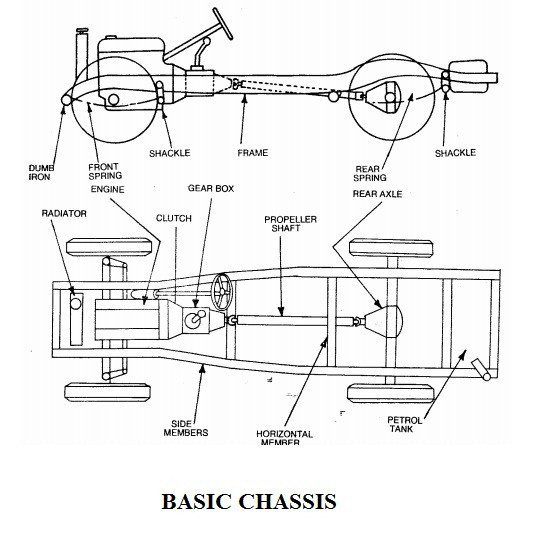

Automobile Chassis | Basic Components of Chassis in an Automobile System

Components of the Automobile chassis The various components of the Automobile chassis and their location in a vehicle can be seen in this picture. Automobile chassis are the skeletal structure and main load-bearing component of a motor vehicle. In popular usage it often refers to an assembled, finished product rather than a bare bones frame. Automobile Chassis is the base on which the vehicle is built. It provides a foundation for attachment of other components and acts as a load-bearing structure. The chassis of an automobile serves the purpose of holding together all its parts and making it move by transferring power from engine to wheels. The chassis holds much […]