Introduction

Sintering is a thermal treatment process used to bond particles together into a coherent, predominantly solid structure via mass transport events that often occur on the atomic scale. This process is primarily used in powder metallurgy but also finds applications in ceramics and other materials. Sintering is a crucial process in materials science and engineering that has revolutionized the manufacturing of metal, ceramic, and composite materials. This article delves into the intricacies of sintering, exploring its fundamental principles, applications, and recent advancements. By understanding this powerful technique, engineers and researchers can unlock new possibilities in material design and production.

What is Sintering?

Sintering is a thermal treatment process that transforms powdered materials into solid, cohesive structures without fully melting them. This remarkable technique occurs at temperatures below the melting point of the primary constituent, typically ranging from 0.5 to 0.8 times the melting temperature of the material. During sintering, atomic diffusion drives the coalescence of particles, reducing porosity and enhancing the strength and density of the final product. This process is fundamental in powder metallurgy and ceramic production, enabling the creation of complex shapes with precise control over material properties.

The Science Behind Sintering

At its core, sintering involves heating a powder compact to a temperature below its melting point (typically 70-80% of the melting temperature) for a specific time. During this process, atoms in the powder particles diffuse across the boundaries of the particles, fusing them together and creating one solid piece.

Key factors influencing the sintering process include:

- Temperature

- Time

- Particle size

- Composition of the powder

- Atmosphere in the sintering furnace

Driving Forces

The primary driving force behind sintering is the reduction of surface energy within the powder compact. As particles fuse, the total surface area decreases, leading to a more thermodynamically stable state. Additional factors influencing the sintering process include:

- Capillary pressure

- Externally applied pressure

- Chemical reactions

Stages of Sintering

Sintering typically progresses through three distinct stages:

- Initial stage: Neck formation between particles and rapid densification

- Intermediate stage: Pore rounding and slow densification

- Final stage: Pore closure and grain growth

Understanding these stages is crucial for optimizing sintering parameters and achieving desired material properties.

Types of Sintering

Several variations of the sintering process exist, each tailored to specific material requirements and applications:

- Solid-state sintering: The most common form, involving only heat treatment

- Liquid-phase sintering: Utilizes a small amount of liquid to enhance densification

- Transient liquid-phase sintering: Temporary liquid formation that disappears during the process

- Reactive sintering: Involves chemical reactions between components during sintering

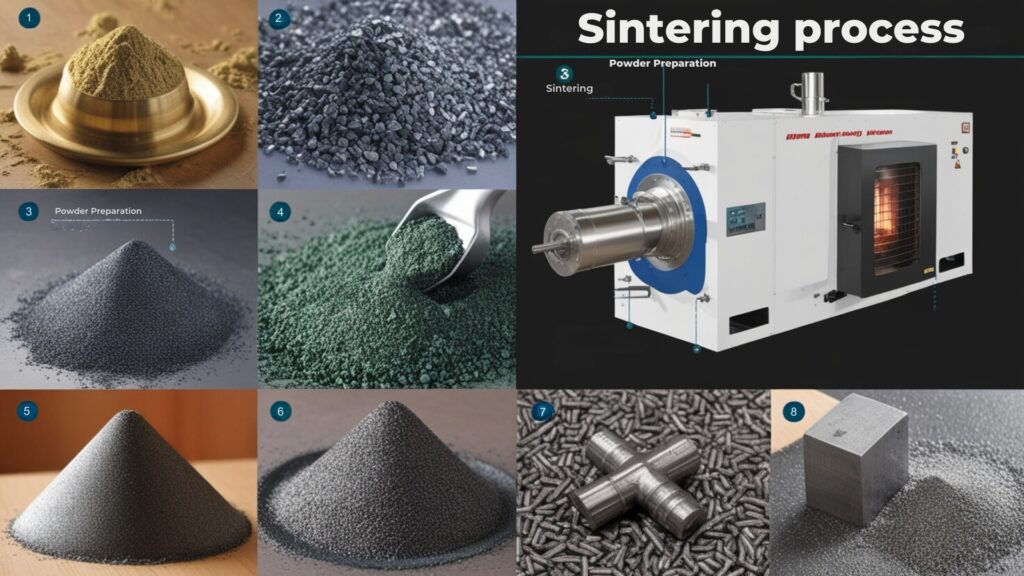

The Sintering Process: Step by Step

1. Powder Preparation

The first step involves selecting and preparing the metal powder. The characteristics of the powder, such as particle size, shape, and distribution, play a crucial role in the final properties of the sintered product.

2. Compaction

The metal powder is then compacted into a desired shape using various techniques such as die compaction, isostatic pressing, or injection molding. This step creates what is known as a “green compact.”

3. Pre-Sintering (Optional)

Some processes include a pre-sintering step where the green compact is heated to a lower temperature. This helps to remove lubricants or binders and initiates the formation of necks between particles.

4. Sintering

The main sintering process occurs in a controlled atmosphere furnace. The temperature is raised to near the melting point of the material, causing the particles to bond together. This step can take several hours, depending on the material and desired properties.

5. Cooling

After sintering, the part is cooled at a controlled rate. The cooling process can significantly affect the final properties of the sintered product.

6. Post-Processing (Optional)

Depending on the application, sintered parts may undergo additional treatments such as machining, heat treatment, or impregnation to enhance specific properties.

Applications of Sintering

Sintering has found its way into numerous industries, revolutionizing manufacturing processes and enabling the creation of complex components that were previously difficult or impossible to produce.

Automotive Industry

In the automotive sector, sintered parts are widely used for:

- Engine components (e.g., connecting rods, camshafts)

- Transmission parts

- Bearings and bushings

These components benefit from the high dimensional accuracy and material efficiency offered by sintering.

Aerospace

The aerospace industry utilizes sintered parts for:

- Turbine engine components

- Structural parts in aircraft

- Heat shields for spacecraft

The ability to create complex geometries and use advanced materials makes sintering invaluable in this high-performance sector.

Medical Devices

Sintering plays a crucial role in the medical field, particularly in:

- Dental implants

- Orthopedic implants

- Surgical instruments

The process allows for the creation of porous structures that promote osseointegration in implants.

Electronics

In the electronics industry, sintering is used for:

- Heat sinks

- Electrical contacts

- Magnetic components

The process enables the production of high-performance materials with specific electrical and thermal properties.

Recent Advancements in Sintering Technology

Spark Plasma Sintering (SPS)

Spark Plasma Sintering, also known as Field Assisted Sintering Technology (FAST), is a cutting-edge technique that combines pulsed direct current with uniaxial pressure. This method offers several advantages over conventional sintering:

- Rapid heating rates (up to 1000°C/min)

- Lower sintering temperatures

- Shorter processing times

- Improved densification

SPS has opened new possibilities for sintering difficult-to-process materials and nanostructured composites.

Microwave Sintering

Microwave sintering utilizes electromagnetic waves to heat materials from the inside out, offering unique benefits:

- Volumetric heating

- Reduced processing times

- Energy efficiency

- Enhanced material properties

This technique has shown promise in ceramic processing and the development of advanced functional materials.

Optimizing the Sintering Process

To achieve optimal results, several factors must be carefully controlled:

- Particle size and distribution: Finer particles generally lead to better densification

- Sintering temperature and time: Higher temperatures and longer times promote densification but may lead to unwanted grain growth

- Atmosphere: Control of the sintering atmosphere can prevent oxidation and influence material properties

- Pressure: Application of external pressure can enhance densification and reduce porosity

Advantages of Sintering

Sintering offers several advantages over traditional manufacturing methods:

- Material Efficiency: Sintering typically results in less material waste compared to subtractive manufacturing processes.

- Complex Geometries: The process allows for the creation of intricate shapes that would be difficult or impossible to achieve with conventional machining.

- Controlled Porosity: Sintering can produce parts with specific levels of porosity, which is beneficial in applications like filters or self-lubricating bearings.

- Cost-Effectiveness: For high-volume production, sintering can be more cost-effective than traditional manufacturing methods.

- Material Versatility: A wide range of materials, including metals, ceramics, and composites, can be processed through sintering.

Challenges and Future Directions

Despite its widespread use, sintering still faces several challenges:

- Control of microstructure: Achieving desired grain size and porosity distribution

- Scalability: Translating laboratory successes to industrial-scale production

- Energy efficiency: Reducing the energy consumption of high-temperature processes

- Novel materials: Developing sintering protocols for emerging materials like high-entropy alloys and metal-matrix nanocomposites

Future research in sintering technology is likely to focus on:

- Advanced simulation and modeling techniques

- In-situ characterization methods

- Integration with additive manufacturing processes

- Development of sustainable and eco-friendly sintering practices

Future Trends in Sintering Technology

As materials science and manufacturing technologies continue to advance, several exciting trends are emerging in the field of sintering:

1. Additive Manufacturing Integration

The combination of 3D printing technologies with sintering is opening up new possibilities for complex geometries and material combinations.

2. Nanomaterials

Sintering of nanoscale powders is an area of active research, promising materials with unprecedented properties.

3. In-Situ Monitoring and Control

Advanced sensors and AI-driven process control are enhancing the precision and reliability of sintering processes.

4. Functional Gradients

Researchers are exploring ways to create materials with gradually changing compositions or properties through sintering.

Conclusion

Sintering remains a cornerstone of materials processing, continually evolving to meet the demands of modern engineering applications. By harnessing the power of atomic diffusion, this versatile technique enables the creation of advanced materials with tailored properties. As research progresses, sintering will undoubtedly play a crucial role in shaping the future of materials science and engineering.

Sintering has established itself as a cornerstone technology in modern manufacturing, enabling the production of high-performance components across a wide range of industries. As research continues and new applications emerge, the importance of sintering in shaping our material world is only set to grow. By understanding the principles, applications, and future trends of sintering, engineers and manufacturers can harness its full potential to create innovative products that meet the demanding requirements of today’s technological landscape.