Introduction

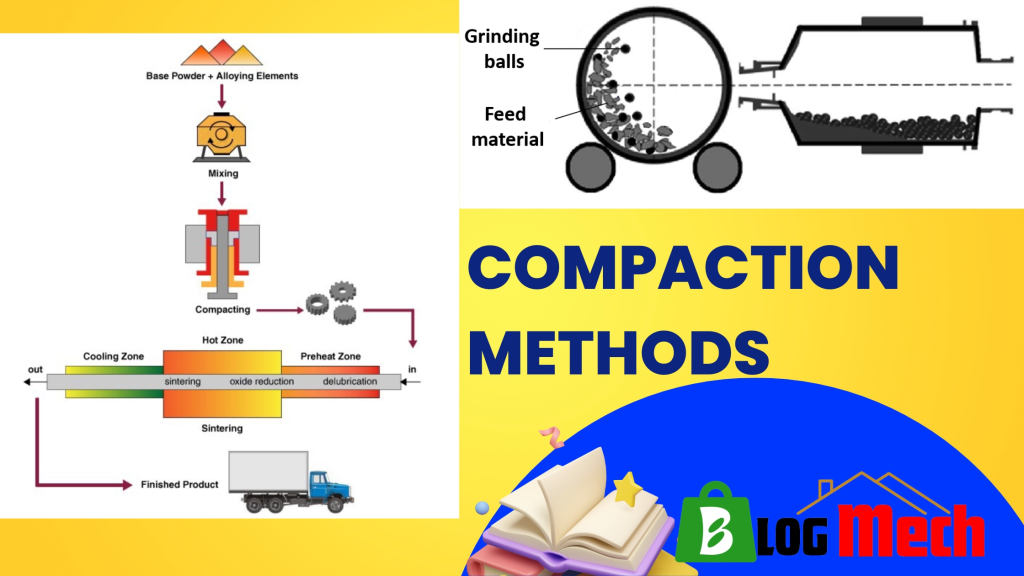

Powder Compaction Methods has revolutionized the manufacturing of complex metal parts, offering unparalleled precision and material efficiency. At the heart of this process lies compaction – a critical step that transforms loose metal powders into solid, usable components. This article delves into the various compaction methods used in powder metallurgy, exploring their principles, applications, and impact on final product quality.

The Fundamentals of Powder Compaction

Compaction in powder metallurgy involves applying pressure to metal powders to create a cohesive “green” part. This process is crucial as it determines the density, strength, and overall quality of the final product. The effectiveness of compaction depends on several factors:

- Powder characteristics (particle size, shape, and distribution)

- Applied pressure

- Die design

- Lubricants and binders used

Understanding Powder Metallurgy Compaction

The Basics of Powder Metallurgy

Powder metallurgy is a manufacturing process that involves the production of metal parts from fine metal powders. The process typically consists of three main steps:

- Powder production

- Compaction

- Sintering

Compaction plays a pivotal role in this process, as it determines the final shape and many of the properties of the finished product.

The Importance of Compaction in Powder Metallurgy

Compaction serves several crucial functions:

- Shaping the powder into the desired form

- Reducing porosity and increasing density

- Enhancing particle-to-particle contact for improved sintering

- Determining the final dimensional accuracy of the part

Traditional Powder Compaction Methods

1. Die Compaction

Die compaction remains the most widely used method in the powder metallurgy industry. It involves filling a die cavity with metal powder and applying pressure using punches.

Die compaction is the most common method used in powder metallurgy. It involves the following steps:

- Filling a die cavity with metal powder

- Applying pressure using punches to compress the powder

- Ejecting the compacted part (known as a “green” part)

Die compaction can be further categorized into:

Single-Action Pressing

In this method, pressure is applied from one direction, typically from the top punch.

Double-Action Pressing

This technique involves applying pressure from both top and bottom punches simultaneously, resulting in more uniform density distribution.

Advantages:

- High production rates

- Excellent dimensional control

- Suitable for a wide range of part sizes

Limitations:

- Density gradients in complex shapes

- Tooling costs for intricate parts

2. Isostatic Pressing

Isostatic pressing applies uniform pressure from all directions, overcoming some limitations of die compaction.

Isostatic pressing involves applying pressure uniformly from all directions. There are two main types:

Cold Isostatic Pressing (CIP)

In CIP, the powder is sealed in a flexible container and then subjected to high pressure via a fluid medium, typically at room temperature.

Hot Isostatic Pressing (HIP)

HIP combines high pressure with elevated temperatures, resulting in fully dense parts with superior mechanical properties. This method is particularly useful for aerospace and medical applications where high performance is critical

Benefits:

- Uniform density distribution

- Ability to produce large, complex shapes

Advantages:

- Near 100% theoretical density

- Improved mechanical properties

- Elimination of internal defects

Advanced Powder Compaction Techniques

1. Warm Compaction

Warm compaction involves heating the powder and tooling to moderate temperatures (typically 130-150°C) during pressing.

Advantages:

- Higher green density

- Improved dimensional stability

- Reduced ejection forces

2. High-Velocity Compaction

This method uses dynamic energy to compact powders in milliseconds.

Benefits:

- Increased density

- Reduced spring-back

- Improved particle bonding

3. Spark Plasma Sintering (SPS)

SPS combines compaction with simultaneous sintering using pulsed electric current.

Advantages:

- Rapid processing times

- Enhanced densification

- Preservation of nanostructures

Specialized Powder Compaction Methods

Metal Injection Molding (MIM)

MIM combines the principles of plastic injection molding with powder metallurgy. The process involves:

- Mixing metal powder with a polymer binder

- Injecting the mixture into a mold

- Removing the binder

- Sintering the part

MIM is particularly advantageous for producing small, complex parts in high volumes.

Additive Manufacturing in Powder Metallurgy

While not a traditional compaction method, additive manufacturing techniques like Selective Laser Sintering (SLS) and Electron Beam Melting (EBM) are increasingly being used in powder metallurgy. These methods offer:

- Unparalleled design freedom

- Ability to produce complex internal structures

- Reduced material waste

Factors Affecting Powder Compaction Quality

Several factors influence the quality of compacted parts:

Powder Characteristics

- Particle size and distribution

- Particle shape

- Flow properties

Compaction Parameters

- Applied pressure

- Dwell time

- Compaction speed

Tooling Design

- Die wall angle

- Punch geometry

- Surface finish of tooling

Lubrication

- Type and amount of lubricant used

- Method of lubrication application

Emerging Trends and Future Outlook in Powder Compaction Methods

1. Additive Manufacturing Integration

The integration of additive manufacturing techniques with traditional powder metallurgy is opening new possibilities for complex geometries and material combinations.

2. Smart Compaction Systems

Advanced sensors and real-time monitoring systems are being developed to optimize compaction parameters on-the-fly, ensuring consistent quality.

3. Sustainable Practices

The powder metallurgy industry is focusing on recycling metal powders and reducing energy consumption in compaction processes.

Applications of Powder Metallurgy Compaction

Powder metallurgy compaction finds applications in various industries:

Automotive Industry

- Connecting rods

- Gears and sprockets

- Valve seats and guides

Aerospace Sector

- Turbine engine components

- Structural parts

- Heat shields

Consumer Electronics

- Heat sinks

- Magnetic cores

- Electrical contacts

Medical Devices

- Dental implants

- Orthopedic implants

- Surgical instruments

Conclusion

Powder Compaction methods in powder metallurgy continue to evolve, driven by the demand for higher performance materials and more efficient manufacturing processes. From traditional die compaction to cutting-edge techniques like spark plasma sintering, each method offers unique advantages for specific applications. As research progresses, we can expect further innovations that will push the boundaries of what’s possible in metal part production.

By understanding and leveraging these advanced powder compaction methods, engineers and manufacturers can create components with superior properties, opening new frontiers in industries ranging from aerospace to medical devices.