Components of the Automobile chassis

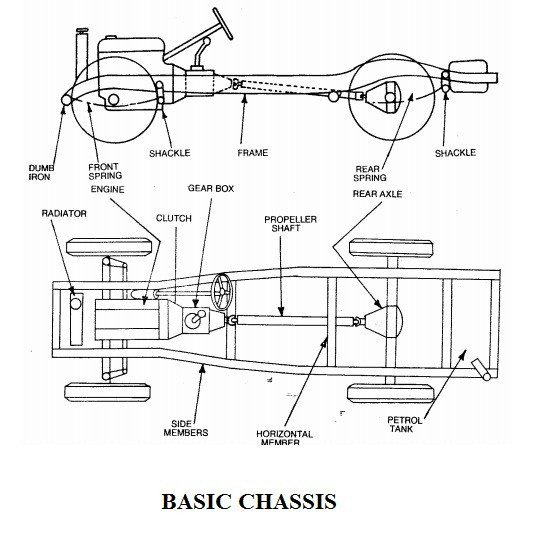

The various components of the Automobile chassis and their location in a vehicle can be seen in this picture. Automobile chassis are the skeletal structure and main load-bearing component of a motor vehicle. In popular usage it often refers to an assembled, finished product rather than a bare bones frame.

Automobile Chassis is the base on which the vehicle is built. It provides a foundation for attachment of other components and acts as a load-bearing structure. The chassis of an automobile serves the purpose of holding together all its parts and making it move by transferring power from engine to wheels. The chassis holds much more than just the drive train; it also holds the electrical system, fuel tank, exhaust system, suspension, brakes and steering gearbox

This article will focus on the components of the automobile chassis and the role each plays in the overall dynamics of a car. The chassis is an integrated system, and it can be difficult to understand how the various parts interact with one another without an in-depth knowledge of all aspects.

The chassis is responsible for holding everything together and distributing forces and loads throughout the vehicle. It also acts as a rigid foundation for all other components in a vehicle like transmission, suspension, axles, etc. As such, it determines the comfort level of passengers.

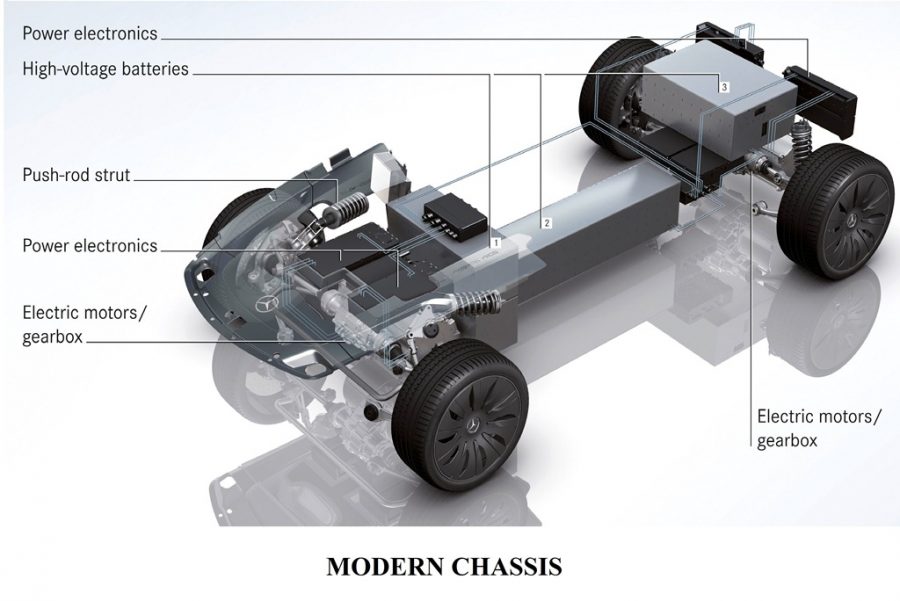

Modern Automobile Chassis construction and Chassis parts list

In the course of automotive development in the 20th century, modern automobile chassis construction and their parts went through a number of changes. The main purpose of these changes was to improve vehicle comfort and safety, as well as fuel economy and engine performance.

The modern automobile chassis is a complex structure that includes many different components. The chassis has multiple parts, including the following:

- Front suspension system;

- Rear suspension system;

- Steering system;

- Braking system;

- Chassis;

- Engine;

- Fuel tank;

- Exhaust system;

- Cooling System;

- Interior of car;

- Electrical systems;

- Body;

Chassis

Chassis – basic parts in automobile chassis system. The name “chassis” comes from the French word “chassis,” which originally meant “frame” or “primary pillar” of a car. All of the main units are used to propel the vehicle, direct its motion, stop it, and allow it to run smoothly over rough surfaces are mounted in the automobile chassis. It serves as the primary mounting point for all parts, including the body. The carrying unit is another name for the automobile chassis system. The main components of the automobile chassis are:

- Engine

- Radiator

- Clutch

- Gearbox

- Universal Joints

- Final Drive

- Differential

- Half axle

- Frame

- Springs and Wheels

- Special dampers

- Electrical system

- Steering system

- Brake system

- Engine control

Engine

Engine produces power required to move the vehicle at the desired speed, overcoming the external resistances. This can be a SI engine or CI engine or gas engine.

Radiator

Radiator is a device used to re-cool the hot engine cooling water for recirculation purpose. The radiator is connected by rubber hoses to the engine, to allow the cooling system water to circulate between them. Other parts of the cooling system are fan, fan belt drive, and water circulating pump.

Clutch

Clutch helps to isolate the engine from the transmission system as and when required. It also permits the vehicle to be started from rest, smoothly and with jerks.

Gearbox

Gearbox provides the torque of the required amount at the driving road wheels. Whenever the resistance to be overcome by the vehicle alters, the gear ratio of the power train is to be changed. The gear box serves precisely this purpose. The gearbox also helps to reverse the vehicle.

Universal Joints

Universal joints cum propeller shaft transmits the torque from the gearbox shaft to the final drive. The gearbox is usually attached to the vehicle frame. The final drive, differential and rear axle are connected to the frame by means of springs. As the tyres of the vehicle hit the bumps in the road, the rear axle moves up and down. The universal joints help the propeller shaft to assume different inclination. The propeller shaft has a sliding arrangement within itself. This helps the shaft to have different lengths when the shaft assumes different inclinations.

Final Drive

Final drive transmits the torque from the longitudinal universal joints cum propeller shaft to the transverse driving half axle shafts and the wheels. The final drive also multiplies the driving torque.

Differential

Differential allows the driving wheels on the two sides of the vehicle to rotate at the same speed when moving over a straight road and at different speeds whenever the vehicle makes a turn.

Half Axle

Half-axle drive shafts transmit the driving torque from the final drive and differential unit to the driving road wheels.

Frame Support

Frame-supports the engine, vehicle body, wheels and other components.

Springs and Wheels

Spring and wheels transmit the vehicle load from the frame to the road. They also damp jerks and shocks when the vehicle wheel hits bumps in the road.

Dampers

Special dampers dampen the resulting oscillations of the springs when the vehicle wheel hits bumps in the road.

Electrical System

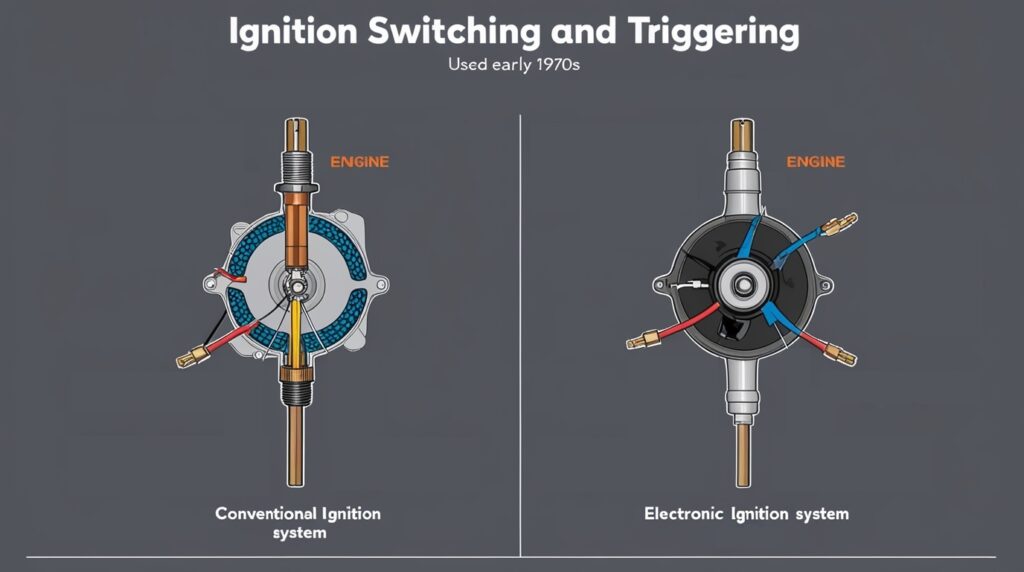

Electrical system in the Automobile chassis consists of a battery, starting motor, generator/alternator, and controls, and in the case of a spark ignition power plant the engine ignition system and lighting arrangement.

Automobile Control System

Controls in a vehicle include steering system, brake system, engine control and power train control.

Steering System

Steering system is used to change the direction of motion of the vehicle by turning the front wheels. The front wheels are linked to the steering wheel which is operated by the driver, by a system of levers and rods.

Brake System

Brake system ensures safe driving of the vehicle. With the brake system, the vehicle can be stopped quickly, or slowed down while going down a slope. The brakes are mounted on all the wheels of a vehicle. The brakes are connected with the brake pedal or lever by means of mechanical, hydraulic or air operated devices.

Engine Control

Engine control refers to the mechanism which permits a variation in the revolutions of the engine crankshaft in accordance with demands. In a vehicle this refers to the accelerator pedal and the connected system.

Power Train

Power train control boils to engaging and disengaging the clutch and the gearbox. These controls, thereby, make the speed and torque variation possible.

Automobile chassis construction can be a very interesting topic for people living in big cities, where the use of automobiles is high. The information about how a automobile chassis is constructed and what parts are used to build it may be of interest to many readers looking for car repair services or those who have no idea how their own automobile works.

Types of Automobile Chassis Frames

An Automobile chassis frames are the backbone of any car. The body of your vehicle, or what you see on the outside, may be pretty but it won’t do anything if the chassis underneath isn’t sturdy enough to support it. Your vehicle’s frame is also one of its most important parts because it holds everything together and makes sure that all of its moving parts are working correctly. A strong frame will prevent your engine from moving around too much while you’re driving, which can lead to premature wear

Automobile Chassis frame sections come in a variety of designs.

1. Channel section

2. Box section

3. Tube section

Non-load supporting frame is another term for traditional frame. The chassis, which is the vehicle’s main skeleton, transfers the vehicle’s loads to the suspension in this kind of frame. Long members use the channel section, while short members use the box section. Three-wheelers, scooters, matadors, and pickup vans all use the tubular section nowadays. The frames must be able to withstand the weight of passengers at abrupt braking and collisions.

Automobile chassis frames support the entire weight of a vehicle and they help to protect the passengers inside from any possible mishaps that could occur on the road. Automobile chassis frames also play a large role in how comfortable a driver feels while he or she is driving.

Conclusion:

The modern automobile is a marvel of engineering. Each vehicle has a complex chassis that consists of the frame, suspension system, and axles. In this article, we will discuss each component in detail so you can understand how they work together to make your vehicle go!

If you are interested in learning more about the components of an automobile chassis, please feel free to comment below.