Drum Brake

The details of the drum brake, a type of manually operated mechanical brake system, can be seen in the picture. The friction is caused by a set of shoes or pads pushed outward against a rotating cylinder-shaped piece known as the drum brakes. Drum brakes have been used on Maybach vehicles since 1900, though Louis Renault didn’t patent the invention until 1902. On the other hand, drum brakes are prone to heat buildup, which can compromise braking performance.

Drum brakes refer to a braking system in which shoes press on the inner surface of the drum. A clasp brake happens when the shoes push on the drum’s exterior. Pinch drum brakes are similar to standard disc brakes in that the drum is pressed between two shoes. Validation brakes are uncommon. A flexible belt or “band” wraps around the outside of the drum in a band brake, for example. Drum brakes are commonly seen on the rear axles of small and compact cars.

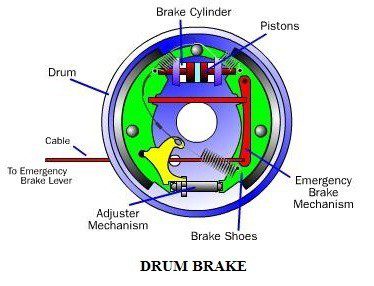

In a motor vehicle, the wheel is attached to a drum. The drum encloses the entire brake mechanism and keeps out dust and moisture. The inner side of the drum is open. The backing plate at the open side of the brake drum completes the brake enclosure and holds the brake assembly. The backing plate is attached to the vehicle axle housing. The backing plate acts as the base for fastening the brake shoes and the operating mechanism. The wheel attaching bolts on the brake drum connects the wheel and the drum. The front coil spring suspension and the drum-type brake mechanism are partly disassembled and can be seen in the picture.

Functions of drum brakes

Drum brakes have been used in automobiles for almost as long as the automobile itself, and they are still used in current cars in a modified and more advanced form. The design principle, which is enclosed cylindrical construction, is referred to as a drum brake.

How The Car Drum Brakes Work

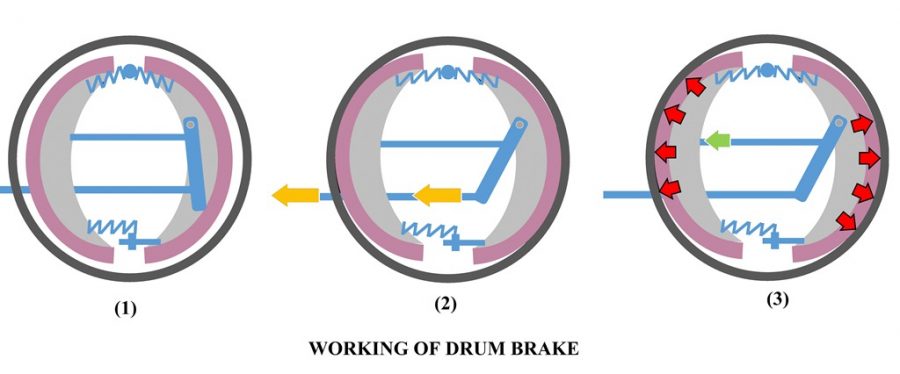

To identify drum brakes in your automobile, you must first understand how they function. You can quickly do maintenance or repairs if you understand how it operates. Drum brakes will function when friction turns into rotational energy or motion energy. The wheel will automatically halt as a result of the movement.

Drum Brake Components

Backing Plate

The backing plate is a relatively thin metal-based band that is put on the rear of the drum brake system and is one of the drum brake components. Other drum brake components are protected by this component. The backing plate is shaped like a circular with numerous holes and protrusions. The major function of the number of holes in the backing plate is to match the drum brake’s standard component.

Wheel Cylinders

Drum brake components are made up of wheel cylinders that transform fluid pressure into mechanical action. In drum braking systems, numerous types of wheel cylinders are often encountered or employed. Because it is frequently employed to complement leading and trailing drum types, the dual-piston wheel cylinder is the most common. The twin-piston-type to the backing plate is best fastened by bolts. The wheel cylinder is made up of various components, including the bleeder nut, piston boot, spring, and piston. The total performance of the drum brakes will be affected if one of the wheel cylinders fails.

Brake Shoes and Pads

Drum brake components such as brake shoes and pads are also common. On a drum brake system, a brake shoe or brake pad is utilized to apply the brake. The brake pad is the location where the brake pads are placed in the disc brake components. Brake shoes are commonly shaped like a circle, with two shoes connected by a semicircle. Because the brake shoe is situated in one location of the drum brake, it will not touch or directly contact the drum. Brake pads are components that are directly applied to the brake shoe’s surface. The material used to make brake pads is an organic ceramic that can be changed or replaced if they get thin or worn out.

Return Spring

The return spring is an important drum brake component that returns the brake shoe to its original position before the brake lever or pedal pressure is applied. The higher spring and the lower spring make form the return spring in the drum brake work system. An upper spring is one that is located on the upper side or beneath the cylinder wheel. The upper spring’s main job is to restore the brake shoe to its original position. The lower spring is positioned on the adjuster’s side and serves a different purpose than the top spring. The bottom spring keeps the two drum brake shoes in place so they may push on the adjuster.

Brake Shoe Holder

The brake shoes will, of course, be put or stored attached to the backing plate in a car drum braking system. The brake shoe holder is mobile or dynamic. As a result, the drum brakes will be adequately supported by the holding mechanism. The brake shoe holder additionally includes a pressure plate and a series of pins with spring or spring locks. When the three pieces are placed together, they form an important portion that connects to the backing plate.

Brake Shoe Adjuster

The brake shoe adjuster is a drum brake component that is placed at the bottom of the drum brake and has a form similar to the adjuster screw. In drum brakes, a brake shoe adjuster is an important component. The brake shoe adjuster adjusts the space between the drum brake pads and the drum surface as the brake pedal moves, whether it’s a small or large movement.

Parking Brake Lever

The parking brake lever is one of the drum brake components found solely in vehicles because it is not utilized on motorcycles. The drum brake structure will appear more sophisticated with the parking brake lever. The park brake lever and the brake shoe link are the two levers that make up the parking brake lever system. The parking brake lever has a hinge on one end that is attached to the brake shoe on the top side, and it is connected to the brake cable at the other end. The brake shoe link, on the other hand, will connect the park brake lever to the opposite brake shoe.

Drum Brake

The drum brake is an important component in the drum brake system’s operation. Because this component is constructed of cast steel, it has a strong texture and a drum-like form. The major function of the drum brake is to provide a medium for friction with the brake pads so that the wheels can stop on the road. This component is likewise directly attached to the wheel bolts, allowing the drum to follow the wheel bolts as they revolve.

Parking Brake Cable

The parking brake cable is a steel cable that is typically used to draw the drum brake system. The steel wire utilized is quite similar to other types of steel cables. The principal function of the parking brake cable is to link the parking brake lever action to the parking brake lever in the drum brake system.

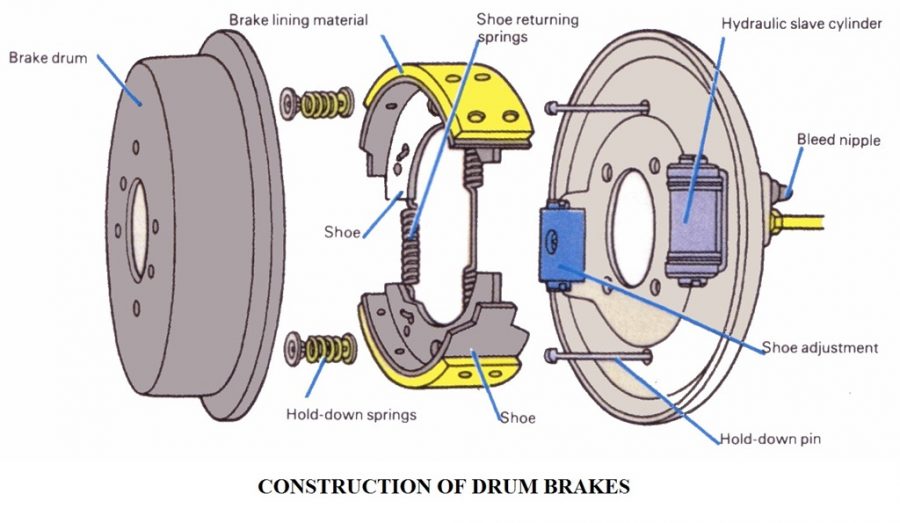

Construction and working of a drum brake system

The details of the drum brake system can be seen in the picture. The brake shoes, which are roughly semicircular, are made to contact the inside surface of the brake drum. In most designs, two shoes are used with each drum to form a complete brake mechanism at each wheel. The brake shoes have brake linings on their outer surfaces. Each brake shoe is hinged at one end by an anchor pin. The anchor pin is fixed to the backing plate. The other end of each shoe rests on a cam. This can be turned by the camshaft, which passes through a hole in the backing plate. The camshaft can be operated by the brake pedal through suitable linkages.

When the cam is turned, the brake shoes expand outward, and the brake linings come into contact with the brake drum. Brake lining increases the coefficient of friction and also prevents the wearing away of the metal. The force of friction is opposite to the direction of drum rotation. The friction between the drum surface and the shoe linings serves to stop or slow down the drum rotation, and hence the wheel rotation.

Working of a drum brake

The friction force that comes into action also tends to make the shoes revolve with the drum. The latter action is prevented by the pin and the cam. The pin is therefore called the anchorage pin.

The magnitude of the friction force, multiplied by the radius of the drum brake, gives the torque tending to stop the drum, that is, the braking torque. The entire mechanical linkage between the brake pedal and the shoes operates to transmit pedal force to the brake shoes and to multiply. The pedal force, through leverage, produces an effective braking force against the drum. The retracting spring is held between the brake shoes. These retracting springs draw the shoes away from the drum when the cam is turned and moved to the release position.

This system, in which the shoes are mounted to rub against the inside surface of the brake drum, is called an internal expanding brake. In this system, each part of the linkage must be free to move. The joints must be properly lubricated to reduce friction and wear. Otherwise, erratic and unequal braking action may result.

Types of drum brakes

Mechanical, hydraulic, and pneumatic assisted drum brakes are the three main types.

Mechanical drum brake

The brake shoes of a mechanical drum brake system, such as on a two-wheeler or an auto-rickshaw, are activated by a cam linked to the brake linkage and pedal. The cam spins when you push the brake pedal. As a result, the brake shoes extend outwards, rubbing on the drum. Because of the friction between the brake linings and the drum, the drum stops rotating, and the wheel comes to a halt. The retracting springs return the brake shoes to their original position when you release the brake pedal. This creates a space between them and the drum, allowing it to spin freely once again.

Hydraulic drum brake

A hydraulic drum brake system, such as that seen in automobiles, is somewhat preferable to a mechanical one. The cam is replaced with a hydraulic wheel cylinder in this configuration. Instead of a cam, the wheel cylinder pistons in the hydraulic system force the brake shoes outwards. The anchor, or braking plate, is where the brake shoes connect. It secures the braking system’s components to the car’s axle.

When you press the brake pedal, the hydraulic energy transmitted to the wheel cylinders is multiplied by the oil in the brake master cylinder. As a result, its pistons push outwards. The brake shoes expand and rub on the drum as a result of the pistons. Because of the friction between the brake linings and the drum, the drum stops rotating, and the wheel comes to a halt.

Pneumatic assisted drum brake:

The pneumatic-assisted drum-brake system, which is operated by air pressure and works on the same principle as the mechanical drum brake system, is the third type. It is also known as the “S-Cam” braking system since it is actuated by a larger size cam or an “S-shaped cam.” However, high-pressure compressed air spins the cam by actuating a pneumatic piston. Drum brakes are used on most medium-to-heavy commercial trucks.

Based on principle, drum brakes are classified as:

Leading/trailing shoe type drum brake

The phrase “leading (or primary) shoe” refers to the shoe that travels in the rotational direction when placed on the drum. The “trailing (secondary) shoe” is the other shoe. The leading shoe is pushed in the same direction as the drums’ rotation, which aids in pressing the shoes against the drum with more force for a larger braking force. The tremendous braking forces of drum brakes are realized through the servo effect (self-boosting effect). It features a wheel cylinder with a piston that generates hydraulic pressure to drive the two shoes against the inner surface of the drum.

The two shoes work in such a way that, depending on whether the vehicle is moving forward or backward, they become the trailing or leading shoe. Whether the vehicle is moving forward or backward, drum brakes provide continuous braking force. Drum brakes produce the same amount of braking force in both directions. This type of brake is often seen on passenger automobiles’ rear brakes.

Twin leading shoe type drum brake

This type of drum brake has two-wheel cylinders and two leading shoes. When the vehicle travels ahead, each wheel cylinder presses on one shoe, causing both shoes to behave as leading ones, delivering stronger braking force.

When the car is in reverse, each of the pistons contained in the wheel cylinders displaces in one direction, so both shoes operate as trailing ones. The front brakes of small to medium-sized trucks often employ this kind.

The pistons of the dual twin leading shoe type displace in both directions, allowing both shoes to operate as the leading ones independent of travel direction. The rear brakes of small to mid-sized trucks often employ this kind.

Duo-servo type drum brake

The duo-servo type has a framework that connects two brake shoes, the primary and secondary shoes, through an adjuster. The main shoe’s servo effect (self-boosting effect) transmits a lot of pressure to the connected secondary shoe, resulting in a lot of braking force.

Parking brakes, truck center brakes, and forklift brakes are all examples of this sort of brake.

Advantages and disadvantages of drum brakes

Advantages of the drum brake system:

- Simple parts and design

- Manufacturing is simple and inexpensive.

- Low-cost maintenance

- Longer life expectancy

Disadvantages of the drum brake system:

- Lower braking force than disc brakes

- When brakes are engaged for an extended period of time, they ‘fade.’

- Asbestos brake shoe lining is hazardous to people.

- Braking grip is significantly reduced when wet.

- Non-asbestos linings absorb moisture and cause drum brakes to unexpectedly grip.

What are the differences between brake pads and brake shoes?

The following are the primary distinctions between brake pads and brake shoes:

Positioning

In their braking system, brake pads and brake shoes are positioned differently. Brake pads are contained within a caliper that surrounds the brake disc, whereas brake shoes are contained within the brake drum.

Wear

Brake shoes have a substantially longer lifespan than brake pads. They are usually mounted on the back axle and provide a significantly smaller percentage of the braking effort.

Do I require brake pads or shoes?

On the same wheel, you cannot mix and match brake pads with drum brakes or brake shoes with disc brakes, but you may have both brake pads and shoes on the same vehicle. In reality, many cars, especially smaller ones, employ a mix of the two, with disc brakes on the front axle and drum brakes on the rear axle.

The direction of the braking force

The force direction is the primary difference between brake shoes and brake pads. The car is pushed outward by brake shoes, while the car is pushed inward by brake pads. Instead of being within a braking drum, brake pads are wrapped around a disc called a rotor. The brake pads are squeezed together by a caliper and pressed on the rotor disc, slowing and halting the vehicle.

Amount of stopping power

The amount of force necessary to bring the vehicle to a complete stop is another contrast between brake shoes and brake pads. Despite the fact that brake shoes contain bigger regions of rough-surfaced material to assist provide the friction needed to stop the automobile, they often lack the stopping strength of brake pads on a disc braking system. When all other parameters are equal, disc brakes give far more stopping force than drum brakes, allowing the vehicle to come to a complete stop faster and across shorter distances.

Life expectancy

Because of their placement within the system, brake shoes may surpass brake pads. Brake shoes may last longer since they are located at the back of the car and are not subjected to as much braking force.

Furthermore, brake shoes are protected from rust, filth, and corrosion by being placed inside the braking drum. However, if dirt or debris gets into the brake drum, it might become stuck, causing the brake shoes to wear out much more quickly. On the other hand, brake pads are more exposed to the environment, driving conditions, and potential dirt and debris. However, because the brake pads basically clean the rotors by wiping dirt and debris off when the brakes are applied, this exposure can help the brake pads and rotors survive longer.

Drum vs Disc Brakes

All four wheels of many modern automobiles feature disc brakes. Disc brakes on the front axle and drum brakes on the rear axle are still used on some versions. Why are there discs on the front? It’s because of weight issues. Because of the engine, an empty vehicle is around 10% heavier in front. When you apply the brakes, the car’s weight shifts to the front. As a result, greater braking force is required upfront, making disc brakes the ideal choice.

Disc vs Drum Brakes: Servicing

It is critical to maintaining disc and drum brakes. Drum brakes feature more hardware and might be more difficult to service when it comes to maintenance. The materials, on the other hand, are less costly than disc brake pads, calipers, and rotors. Disc brakes are easier to repair since they have fewer components. The automobile is one of those vehicles with several constituent components, each with its own set of functions. Brakes are an important part of an automobile since they may slow or stop it while traveling forward or backward. Cars have two types of brakes: disc brakes and drum brakes, which are the most common.

Both types of brakes have the same goal: to stop the car, but disc brakes are built differently from drum brakes. The operating system is also distinct due to the many components it transports. Many individuals who own automobiles are still unaware of the concept of drum brakes. Drum brakes are made up of several parts. Drum brakes typically have at least some components.

Which is better: drum or disc brakes on a scooter?

Riding at greater speeds has become the new normal, thanks to smoother and broader roads and improvements in bike power. With such high travel speeds and a rapid tempo of travel, braking power must be improved. What if you’re riding at a fast pace and an impediment appears in your path? All you need at that point is hard braking and a short stopping distance. Traditional drum brakes were replaced by disc brakes at this point.

Even the majority of the front wheels on scooters now have disc brakes. According to studies, the front wheels are 70 percent more efficient than the rear wheels at controlling speed. Disc brakes don’t have all of the benefits that drum brakes have. Drum brakes offer their own set of benefits, and the rider is free to choose his preferred braking system. Disc brakes don’t have all of the benefits that drum brakes have. Drum brakes offer their own set of benefits, and the rider is free to choose his preferred braking system.

How to Adjust Drum Brakes

Have you ever experienced a delay in deceleration after using the brakes? This is a strong indication that your drum brakes need to be adjusted or replaced. Despite their durability, drum brakes can begin to drag after extended usage, resulting in grinding sounds. The noise indicates that the brake shoes have been worn out. Bad brake shoes can cause serious damage to the wheel drum if not addressed, which will cost more money to repair. Regular adjustment of these brakes, on the other hand, ensures that they respond swiftly whenever you apply them. Because your life is on the line, you must always double-check your brakes before hitting the road.

Step 1: Suspend your back wheels by jacking them up.

Use the parking brakes to correctly park your car. Locate a jacking position near the back wheels and use it to lift one side of the car off the ground. To keep the automobile in position, use a jack stand. Repeat the procedure on the opposite side of the wheel.

Step 2: Take off the tyres.

Remove the tyres after raising your car. Remove the lug nuts from the wheels gently. Keep the nuts in a secure location where you can readily get them.

Step 3: Adjust the drum brakes.

Locate the drum brake adjustment first and foremost. The brake adjuster is located at the back base of the brake drum and is easily accessible. Using a flat screwdriver, remove the dust cover. To determine where you need to turn the brake adjustment, spin it clockwise or anticlockwise. It’s worth noting that the majority of drum brake adjustments are made in a clockwise manner. The brake adjustment rises upward as you apply downward pressure to the screwdriver, bringing the brake shoes closer to the drum.

Make sure there’s little drag so you can stop quickly. The brake will not operate correctly if the drag is excessive. You should do the same on the opposite wheel once the tyre can spin with a little drag (not freely or aggressively). To observe how it is, drag the hand brake lever. Add extra tweaks if it’s too loose.

Step 4: Review your work.

Reinstall the dust cover to its original place once the brake has been set to your satisfaction. Make sure everything is in place and secure.

Step 5: Set up your tyres.

Replace the automobile tyres that were previously removed. After that, use a ratchet and socket or wheel spanners to tighten the lug nuts until they are tightly installed.

Step 6: Lower the vehicle

Place your jack on the jacking area and lift the automobile until the jack stand can be securely removed. Lower the car and repeat on the opposite side of the steering wheel.

Step 7: Vehicle evaluation

Before driving, pump the brake pedal a few times. Then, drive to a safe spot and check to see whether the brakes are working correctly. If your brakes are working, you’re good to go! Whether you’re hauling a trailer and your brakes fail, you should inspect your braking system components to determine if they need to be adjusted. The preceding instructions are comparable to how to adjust trailer drum brakes.

FAQs:

Q: Drum brakes are adjusted in which direction?

Adjusting your drum brakes is rather simple. You must, however, understand which way to press the adjuster. The appropriate way to spin the adjuster in most automobiles is clockwise, although a few others are built to function anti-clockwise. The adjustment wheel goes upwards or clockwise when you press the adjuster lower with your screwdriver.

Q: Will the drum brakes adjust themselves?

When there is a large gap between the brake and the drum, most current automobiles include an automated adjuster that detects the problem and resets itself when the emergency brakes are applied.

The automatic adjuster, on the other hand, will not adjust if you don’t use the emergency brake for a long period.

Q: In reverse, do drum brakes self-adjust?

Yes, the automatic adjuster adjusts itself anytime you engage your brakes when reversing.

When you back off, a lever adjusts the brake system and slightly adjusts the wheel. However, this does not apply to all automobiles, and it is not a complete solution for adjusting your brakes when they are malfunctioning.

Q: How often should the drum brakes be adjusted?

A drum brake requires adjustment every 10,000 miles or sooner until it needs to be replaced. However, there are a few signals that your brake shoes need to be adjusted. So, if you’re wondering how to determine whether your drum brakes need to be adjusted, keep an eye out for these signs.

- The back wheels are making a strange or grinding noise.

- The parking brake lever is missing.

- While using hand brakes, the automobile travels smoothly.

When your brakes are malfunctioning, the ABS light illuminates. When you notice the light come on, pull over to a safe location and inspect your braking system components.

Drum Brake Self-Adjusters: What They Mean

When the shoes are seated to the drum in a disc/drum installation, the automatic adjusters are critical for ensuring appropriate brake balance. Premium replacement shoes have eccentrically ground linings to provide space at the heel and toe. The adjustment will be the most active for the first 100 miles or so, keeping the brake pedal at the optimum height. The adjuster will turn the notched wheel in small amounts once the shoes have been inserted. The adjusters should be replaced to guarantee adequate brake application and pedal height.