Introduction

Disc brakes are a crucial component of modern vehicle safety systems, providing reliable and efficient stopping power. This comprehensive guide delves into the intricacies of disc brake construction, operation, and maintenance, offering valuable insights for automotive enthusiasts, mechanics, and everyday drivers alike.

The Evolution of Braking Systems

Before we dive into the specifics of disc brakes, it’s essential to understand their place in the evolution of automotive braking systems:

- Early Drum Brakes: The first automobiles used simple drum brake systems, which were prone to overheating and fading during prolonged use.

- Introduction of Disc Brakes: Disc brakes were first patented in 1902 but didn’t see widespread automotive use until the 1950s.

- Modern Advancements: Today’s disc brakes incorporate advanced materials, computer-controlled systems, and regenerative braking in electric vehicles.

Mechanical Braking System – Disk Brakes

Internal expanding shoe brakes i.e. disk brakes, are the generally used braking system in automobiles. In an automobile, the wheel is fitted on a wheel drum. The brake shoes are fitted in contact with inner surface of this drum to apply brakes.

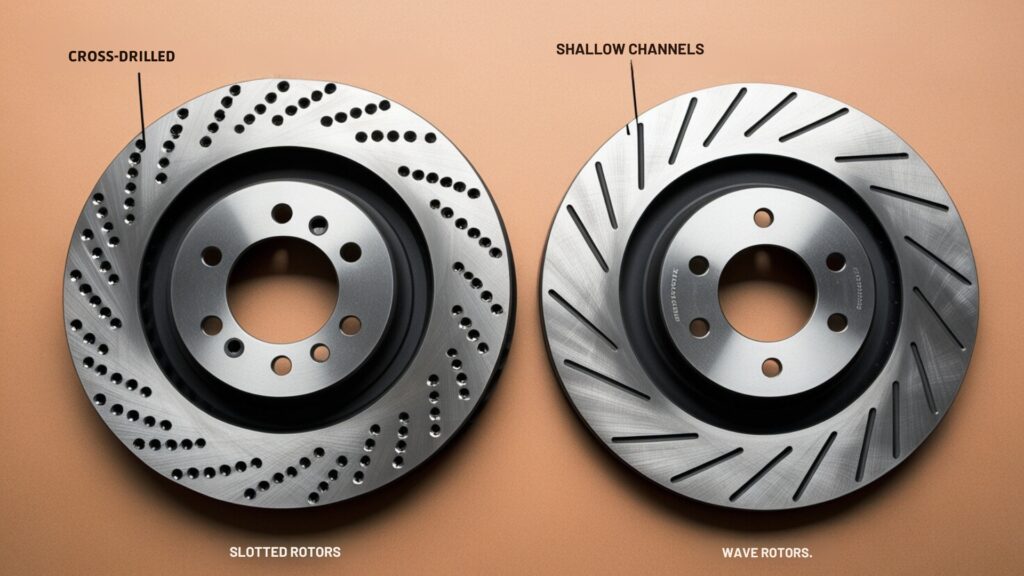

Types of Disc Brake

Several variations of disc brakes exist, each with specific applications:

- Cross-Drilled Rotors: Feature holes drilled through the rotor to improve cooling and reduce weight.

- Slotted Rotors: Have shallow channels cut into the surface to improve pad bite and gas evacuation.

- Wave Rotors: Have a wavy outer edge to reduce weight and improve cooling.

- Carbon-Ceramic Rotors: Used in high-performance vehicles for their lightweight properties and heat resistance.

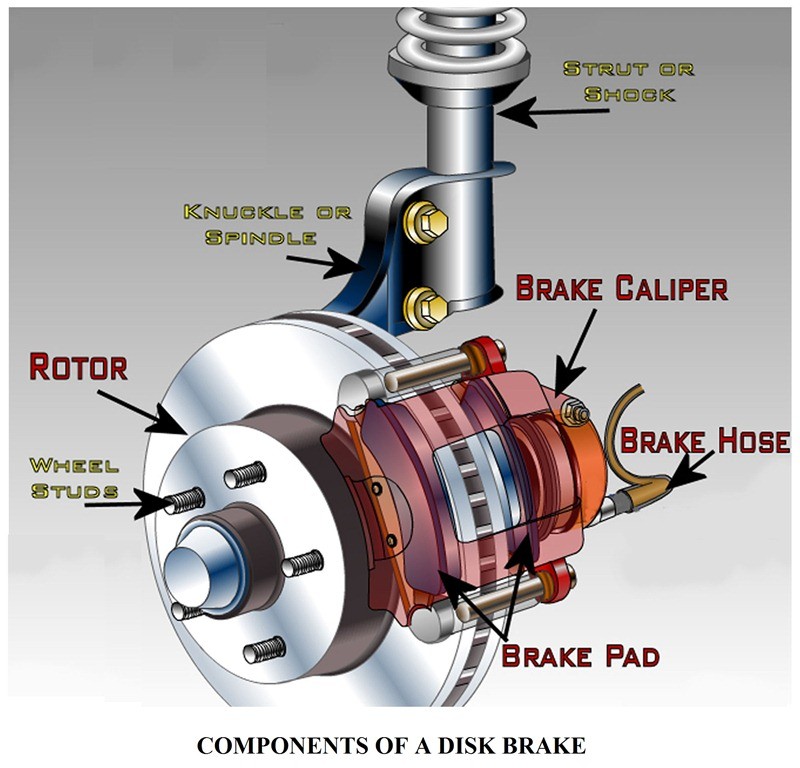

Construction and Working of Disk Brakes in an Automobile

The construction of mechanical disk brake is shown in picture. The whole assembly contains of a pair of brake shoes with brake linings, two anchor pins and retractor spring, a cam and a brake drum. Brake linings are attached on outer surface of each brake shoe.

The brake shoes are hinged at one end by means of anchor pins. Last end of brake shoe is functioned by a cam to expand it out counter direction to brake drum. Retracting springs provided are used for bringing the shoes to their original position when brakes are not applied. The brake drum closes inside it the entire mechanism to protect it from dust and sand. A plate holds the total assembly and fits to car axle. It also acts as a base to fasten the brake shoes and other operating mechanism.

How Disc Brakes are Applied and Released

When brake pedal is pressed, the cam turns through brake linkages. Brake shoes expand towards brake drum due to turning of cam. The brake linings, rub against brake drum and therefore motion of wheels is stopped. The pedal force is transmitted to the brake shoes through a mechanical linage. This device also multiplies the force to apply the brakes effectively. When force on brake pedal is removed, the retractor spring brings the shoes back to original position and brakes are released.

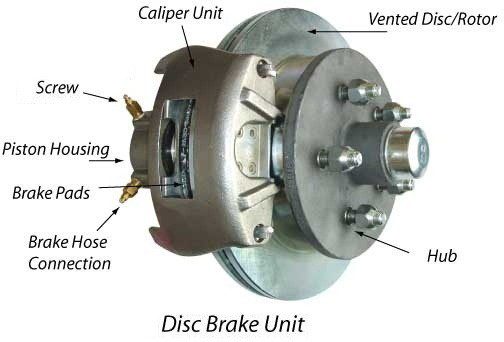

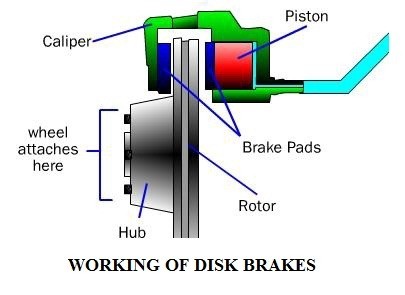

Construction and Working of disk brakes

Modern motor cars are fitted with disc brakes instead of conventional drum type brakes. Front wheels are generally has disc brakes whereas rear wheel are provided with drum brakes. A disc brake contains a rotating disc and two friction pads which are actuated by hydraulic braking system as described earlier. The friction pads stay free on each side of disc when brakes are not applied. When brakes are applied they rub in contradiction to the disc to stop the vehicle. The working of this brake is the same method as that of hydraulic brakes. But the way of stopping the vehicle is not the same as that of drum brakes.

Brake Rotor Design

- Material: Most rotors are made from cast iron, which offers good heat dissipation and wear resistance. Some high-performance vehicles use carbon-ceramic rotors for improved performance and reduced weight.

- Ventilation: Many rotors feature internal vanes to improve cooling. These vented rotors have better heat dissipation capabilities compared to solid rotors.

- Surface Finish: The rotor’s surface is machined to precise specifications to ensure smooth operation and even pad wear.

Brake Pad Construction

- Friction Material: The composition of brake pads varies, with options including metallic, semi-metallic, ceramic, and organic materials. Each type offers different performance characteristics.

- Backing Plate: This metal plate provides structural support for the friction material and attaches the pad to the caliper.

- Shims: These thin metal or rubber components are often added to reduce noise and vibration.

Caliper Design

- Fixed Calipers: These have pistons on both sides of the rotor and are typically used in high-performance applications.

- Floating Calipers: More common in passenger vehicles, these have pistons on one side and move laterally to apply force to both sides of the rotor.

- Materials: Calipers are usually made from cast iron or aluminum alloys, balancing strength, weight, and cost considerations.

Working of disk brakes

In a disc brake, the fluid from the master cylinder is forced into a caliper where it presses against a piston. The piston in turn crushes two brake pads against the disc, that is being attached to wheel, making it to stop or slow down.

Working Principles of Disc Brakes

Understanding how disc brakes operate is crucial for appreciating their efficiency:

- Hydraulic Pressure: When the brake pedal is pressed, it creates hydraulic pressure in the brake lines.

- Piston Movement: This pressure causes the pistons in the brake calipers to extend.

- Pad Compression: The pistons push the brake pads against the rotating disc.

- Friction and Heat: The friction between the pads and the disc slows the rotation of the wheel, converting kinetic energy into heat.

- Heat Dissipation: The rotor’s design allows for rapid heat dissipation, preventing brake fade during prolonged use.

Advantage of Disc Brakes

- Main advantage of disc brakes is their resistance to wear as the discs remain cool even after repeated brake applications.

- Brake pads are easily replaceable.

- The condition of brake pads can be checked without much dismantling of brake system.

- Superior Heat Dissipation: The exposed disc allows for better cooling, reducing the risk of brake fade.

- Improved Performance: Disc brakes provide more consistent stopping power and better modulation.

- Self-Cleaning: The centrifugal force of the spinning disc helps keep the braking surface clean.

- Simplified Maintenance: Disc brakes are generally easier to inspect and service than drum brakes.

- Weight Reduction: In many cases, disc brake systems are lighter than equivalent drum brake systems.

Disadvantage of Disc Brakes

- More force is needed be applied as the brakes are not self-emerging.

- Pad wear is more.

- Hand brakes are not much effective if disc brakes are used in rear wheels also.

Maintenance and Care of Disc Brakes

Proper maintenance is crucial for ensuring the longevity and performance of disc brakes:

- Regular Inspections: Check brake pads, rotors, and calipers for wear or damage.

- Pad Replacement: Replace brake pads when they reach the minimum thickness specified by the vehicle manufacturer.

- Rotor Resurfacing or Replacement: Resurface or replace rotors when they become excessively worn or warped.

- Brake Fluid Maintenance: Regularly check and replace brake fluid as it can absorb moisture over time, reducing its effectiveness.

- Caliper Maintenance: Ensure caliper slides are clean and well-lubricated for smooth operation.

Common Disc Brake Issues and Troubleshooting

Familiarity with common disc brake problems can help in early diagnosis and resolution:

- Squealing or Squeaking: Often indicates worn brake pads or the need for anti-squeal shims.

- Pulsating Brake Pedal: Usually a sign of warped rotors, requiring resurfacing or replacement.

- Soft or Spongy Brake Pedal: May indicate air in the brake lines or deteriorating brake fluid.

- Pulling to One Side When Braking: Could be caused by a stuck caliper or uneven pad wear.

- Grinding Noise: Often signals that brake pads have worn down completely and are damaging the rotors.

Advancements in Disc Brake Technology

The field of disc brake technology continues to evolve:

- Electric Parking Brakes: Replace traditional hand or foot-operated parking brakes with electronic actuation.

- Brake-By-Wire Systems: Use electronic signals instead of hydraulic pressure to activate brakes, offering more precise control.

- Regenerative Braking: Used in hybrid and electric vehicles to recover energy during braking.

- Adaptive Brake Systems: Adjust braking force based on driving conditions and vehicle load.

- Autonomous Emergency Braking (AEB): Automatically applies brakes to prevent or mitigate collisions.

Choosing the Right Disc Brakes for Your Vehicle

When upgrading or replacing disc brakes, consider the following factors:

- Vehicle Type and Use: Performance cars, daily drivers, and heavy-duty vehicles have different braking requirements.

- Driving Conditions: Consider factors like climate, terrain, and typical driving patterns.

- Budget: Balance performance needs with cost considerations.

- Compatibility: Ensure any aftermarket components are compatible with your vehicle’s existing systems.

- Legal Considerations: Be aware of any regulations regarding brake modifications in your area.

Conclusion

Disc brakes are a critical safety component in modern vehicles, providing reliable and efficient stopping power. By understanding their construction, working principles, and maintenance requirements, vehicle owners can ensure optimal brake performance and longevity. As automotive technology continues to advance, we can expect further innovations in disc brake design, leading to even safer and more efficient braking systems in the future.

Regular maintenance and prompt attention to any brake-related issues are essential for ensuring your vehicle’s safety on the road. Whether you’re a DIY enthusiast or prefer professional servicing, staying informed about your vehicle’s braking system is crucial for safe and confident driving.