Introduction

The automobile ignition system is a critical component in internal combustion engines, responsible for generating the spark that ignites the air-fuel mixture and powers the vehicle. Originating in the late 19th century, early ignition technologies, such as the trembler coil, paved the way for significant advancements, including the electric self-starter patented by Charles Kettering in 1912, which revolutionized vehicle operation by eliminating the need for manual cranking.

This innovation not only enhanced accessibility but also marked a turning point in automotive design and functionality, particularly for women in the early 20th century. Modern ignition systems consist of various essential components, including the battery, ignition coil, spark plugs, and electronic controls that optimize spark timing for improved performance and reduced emissions. The evolution from mechanical systems to sophisticated electronic configurations has enabled significant gains in efficiency, making contemporary vehicles more reliable and environmentally friendly.

Notably, advancements such as the distributor-less ignition system (DIS) have further streamlined spark generation, enhancing engine responsiveness and performance. Controversies surrounding ignition systems often arise from issues related to maintenance and reliability. Common problems include failure to start due to faulty components, which can lead to costly repairs and inconveniences for vehicle owners.

Moreover, the shift towards hybrid and electric vehicles poses new challenges and opportunities for ignition technology as the industry adapts to changing regulations and consumer preferences for sustainability. As the automotive landscape continues to evolve, the future of ignition systems is characterized by ongoing innovations, particularly in battery technology and electronic controls. These advancements are crucial for meeting stringent emissions standards and enhancing the overall driving experience, solidifying the ignition system’s role as a foundational element in modern vehicle design.

History

The history of automobile ignition systems traces back to the late 19th century, when early vehicles relied on simple ignition methods. The introduction of the trembler coil revolutionized ignition technology, first used in the 1886 Benz Patent-Motorwagen and later in the Ford Model T, which utilized four coils—one for each cylinder—to generate multiple sparks during each power stroke. The trembler coil operated on the principle of a vibrating interrupter, allowing for high voltage generation crucial for engine ignition.

In 1912, Charles Kettering patented an electric self-starter system that significantly altered the landscape of ignition technology. His system allowed drivers to start their vehicles without the need for hand-cranking, which had been a common method until then. The electric self-starter is credited with making driving more accessible, especially for women, contributing to the societal changes during the Roaring ’20s, a period marked by increased female independence and mobility. Subsequent developments in ignition systems included the introduction of manual spark advance systems by Packard in 1901, which allowed drivers to control the timing of the spark ignition through a lever.

This was further enhanced in the 1930s with Studebaker’s vacuum advance and Chrysler’s combination vacuum and centrifugal advance unit, which automated spark timing adjustments based on engine conditions. As technology advanced, the design of ignition systems continued to evolve. Modern ignition coils have replaced the trembler coil, using a more precise method to generate a single spark per cycle, thus enhancing efficiency and performance. By the 1980s, the introduction of onboard computers revolutionized spark timing with three-dimensional timing maps, making ignition systems more sophisticated and reliable than ever before.

Components

The ignition system of an automobile is a crucial component responsible for starting the engine and ensuring its proper operation. It comprises several essential parts, each playing a specific role in the ignition process.

Main Components

Battery

The battery provides the initial power necessary to start the vehicle. It supplies electrical energy to turn over the engine’s internal combustion process, initiating the car’s operation.

Ignition Switch

The ignition switch controls various electrical components, including headlights, wipers, and the car’s audio system. Modern vehicles often feature electronic ignition switches that can be operated remotely or via a push-start button.

Ignition Coil

The ignition coil transforms low-voltage electrical current from the battery into a high-voltage pulse required to create the spark. It consists of a primary winding, a secondary winding, and a magnetic core, enabling the ignition system to ignite the air-fuel mixture effectively.

Spark Plugs

Spark plugs are threaded into the combustion chamber and generate the spark that ignites the air-fuel mixture. They are designed to withstand extreme conditions within the combustion chamber and must be replaced periodically due to wear.

Spark Plug Wires

Also known as ignition cables or leads, spark plug wires transmit high-voltage electrical current from the ignition coil to the spark plugs. These wires are crafted from high-resistance materials to prevent electrical interference and ensure reliable spark generation.

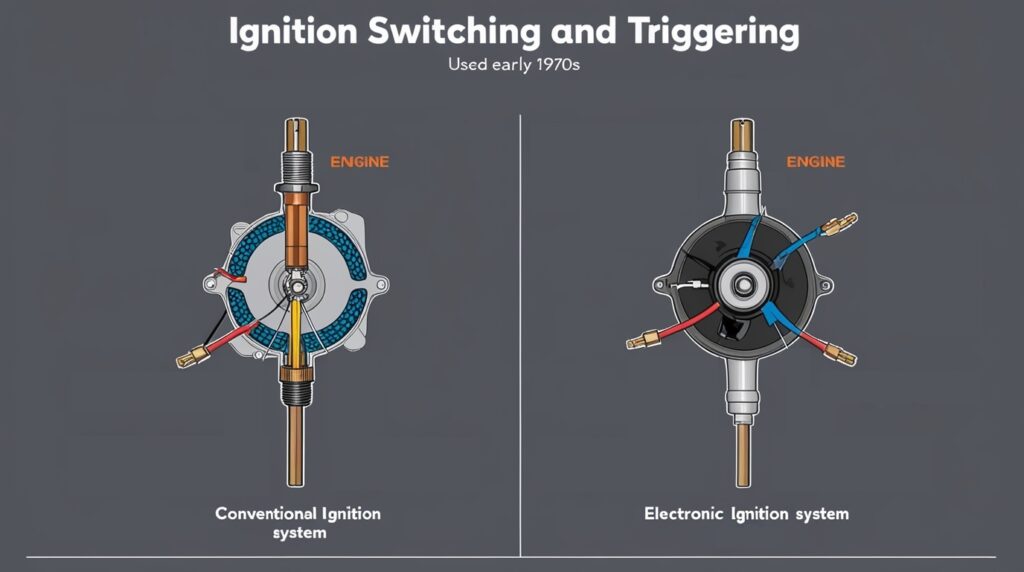

Distributor

In conventional ignition systems, the distributor controls the timing and distribution of the spark to each cylinder. It uses a rotating rotor and either mechanical contact points or electronic sensors to regulate spark timing.

Sensors

Modern electronic ignition systems utilize various sensors, such as the crankshaft position sensor and camshaft position sensor, to gather information about the engine’s operating conditions. This data is essential for controlling ignition timing accurately.

Distributor-less Ignition System

Many contemporary engines employ a distributor-less ignition system (DIS) or direct-ignition system. In these configurations, high-voltage pulses are directly applied to coils positioned atop the spark plugs. This system includes components like a coil pack, ignition module, crankshaft reluctor ring, and electronic control module, allowing for precise ignition timing based on real-time engine data. Together, these components ensure that the ignition system operates efficiently, facilitating reliable engine starts and optimal performance.

Types of Ignition Systems

There are several subtypes of ignition systems, each designed for specific applications:

- Battery Ignition System (Coil Ignition System): Utilizes a 12-volt battery to power the ignition circuit, consisting of primary and secondary circuits that facilitate spark generation.

- Magneto Ignition System: Commonly used in small engines, it generates its own electrical energy through magnetic induction and does not rely on a battery.

- Coil-on-Plug Ignition System: Each spark plug has its own ignition coil, providing direct and efficient spark generation for improved engine performance. This system may also operate in a “wasted spark” mode, where one plug fires during exhaust stroke, ensuring optimal ignition timing.

Operation

The operation of an automotive ignition system is crucial for the effective functioning of internal combustion engines. The ignition system generates a spark that ignites the air-fuel mixture in the engine’s cylinders, initiating the combustion process that powers the vehicle. This process begins when the key is turned in the ignition switch, sending a signal to the vehicle’s computer. The computer processes data from various sensors, such as those monitoring engine position, mass air flow, and RPM, to determine the appropriate spark advance for each cylinder.

Once the spark advance is calculated, the controller signals the ignition driver circuit to produce a high-voltage current. This current travels through the ignition coil, distributor, and high-tension cables to the spark plugs. The spark plugs then generate electric sparks across their gaps, igniting the compressed air-fuel mixture within the combustion chamber. As the air-fuel mixture ignites, it generates pressure that pushes the pistons down, turning the crankshaft and propelling the vehicle forward.

Modern ignition systems often employ electronic controls for enhanced precision and efficiency. Unlike older mechanical systems that used carburetors and distributor points, contemporary electronic ignition systems enable more accurate timing of the spark, which is vital for optimizing engine performance and reducing emissions. These systems can operate multiple spark plugs in pairs through common coils, further improving efficiency.

In contrast, diesel engines utilize compression ignition, which ignites the fuel-air mixture through the heat generated by compression rather than a traditional ignition system. However, they may include glow plugs to preheat the combustion chamber for easier starting in cold conditions. Thus, while the fundamental operation of ignition systems varies across engine types, their primary role remains the initiation of combustion to ensure engine functionality.

Performance

The performance of automobile ignition systems has seen significant advancements, particularly with the introduction of electronic ignition systems. Testimonials from users highlight notable improvements in engine efficiency and operation. For instance, one user reported a significant enhancement in the performance of a ’67 Cessna 206 after installing the Lycoming EIS-61000 electronic ignition system. The user noted that hot starts became much easier, and the engine exhibited smoother operation across various phases, especially at high altitudes, leading to better climb rates and reduced ground roll during take-off.

Moreover, the science behind ignition voltage is crucial to understanding performance. The spark voltage is primarily influenced by the spark plug gap, with higher voltages typically occurring under load conditions, such as wide-open throttle. This operational characteristic is sometimes misrepresented, as the “50,000 volts” often cited refers to peak voltage under specific conditions rather than what is continuously delivered during regular engine operation.

The development of the Lycoming EIS reflects a commitment to performance enhancement, having undergone extensive research and testing to ensure reliability and effectiveness. The system’s implementation in models like the CubCrafters CC-19 XCub demonstrates its practical applications and advantages in modern aviation engines, which parallels advancements in automotive technology. Routine maintenance of ignition systems is essential to sustain performance.

Regular check-ups, clean contacts, and inspection of wiring can help maintain optimal functionality. These measures, coupled with electronic systems that use sensors for precise timing, result in enhanced fuel efficiency and lower emissions, showcasing the evolution of ignition technology from mechanical to electronic systems. As performance expectations continue to rise, understanding and optimizing ignition system capabilities remain critical for both aviation and automotive applications, driving innovations that keep engines operating efficiently and reliably.

Innovations and Future Trends

Technological Advancements in Ignition Systems

The automotive ignition system is evolving rapidly, driven by technological advancements that enhance efficiency, performance, and compliance with stringent emission regulations. The transition from traditional distributor-based systems to electronic ignition systems exemplifies this evolution.

These modern systems utilize electronic controls to optimize the timing of ignition, improving engine performance and reducing emissions significantly. Innovations such as direct ignition systems eliminate the need for a distributor, allowing for better fuel ignition in each cylinder, which further boosts fuel efficiency.

Hybrid Technology and Sustainability

As the automotive industry shifts toward sustainability, hybrid technology is at the forefront of innovation. The integration of advanced ignition systems into hybrid vehicles is crucial for reducing emissions and improving fuel efficiency. Plug-in hybrid vehicles are expected to feature extended electric-only ranges due to advancements in battery technology, enabling drivers to rely more on electric power. Additionally, the focus on streamlined aerodynamics and lightweight materials will contribute to the overall efficiency and performance of hybrid vehicles.

Advanced Battery Technologies

The future of ignition systems also aligns with advancements in battery technologies, particularly the anticipated adoption of solid-state batteries. These batteries promise higher energy density and faster charging times, significantly enhancing the performance of hybrid vehicles. As automotive manufacturers continue to invest in research and development, the integration of smart grids will allow hybrid vehicles to interact dynamically with the electrical grid, optimizing energy management and supporting sustainability efforts.

Market Growth Opportunities

The growing demand for advanced ignition systems is further fueled by increasing environmental consciousness and regulatory requirements. With governments worldwide tightening emission standards, there is a pressing need for ignition systems that ensure compliance while enhancing operational efficiency and fuel economy. As a result, manufacturers are expected to explore opportunities for the development of smart ignition systems that can optimize combustion processes and minimize emissions.

Key Figures and Companies

The automobile ignition system market is characterized by the involvement of several key players and influential figures whose innovations have significantly impacted the industry.

Influential Figures

Charles Kettering

One of the most notable figures in the development of ignition systems is Charles Kettering, an engineer and inventor who served as the head of research and development for General Motors. He is best known for inventing the electric self-starter, which was first introduced in the 1912 Cadillac. This invention not only revolutionized automobile ignition systems but also facilitated greater independence for women in driving during the early 20th century.

Major Companies

Several companies play a pivotal role in the automotive ignition system market, contributing to technological advancements and market dynamics.

- Robert Bosch GmbH (Germany): A leading supplier known for its extensive range of automotive components, including ignition systems.

- Hitachi Ltd. (Japan): A significant player in the automotive sector, focusing on advanced ignition technologies.

- Honeywell International Inc. (U.S.): Offers a variety of ignition solutions and is known for its innovation in automotive components.

- BorgWarner Inc. (U.S.): Provides a broad array of ignition systems and components to various automotive manufacturers.

- Denso Corporation: Renowned for its high-quality ignition parts and systems, contributing significantly to the global market.

- Continental AG: A major supplier of ignition systems and other automotive technologies within the Schaeffler Group. These companies are involved in various aspects of the ignition system supply chain, from manufacturing components like spark plugs and ignition coils to offering advanced technologies aimed at enhancing vehicle performance and efficiency.

Troubleshooting Techniques

Troubleshooting an automobile ignition system can be a complex yet rewarding challenge for car enthusiasts and everyday drivers alike. Understanding common issues and implementing effective diagnostic strategies can help mitigate problems and reduce repair costs.

Common Ignition Issues

One of the primary issues that car owners face is a faulty ignition system, which can lead to difficulties in starting the vehicle or may even cause the engine to stall while driving. Key signs of ignition problems include intermittent starting issues, where the engine may struggle or fail to start altogether. These problems can arise from several sources, including a defective ignition switch, worn-out spark plugs, or a malfunctioning starter motor.

Basic Troubleshooting Steps

To begin troubleshooting, check all components of the ignition system, such as spark plugs, wires, and coils. It’s essential to inspect the starter and solenoid as well, as a faulty part may require replacement. If the ignition system remains unresponsive after checking these elements, consider rewiring the entire system, as it may seem daunting but can often be managed by following the vehicle’s operations manual.

If basic checks do not resolve the issue, consult with a professional mechanic who possesses the necessary skills and tools to diagnose complex problems effectively. Mechanics often utilize diagnostic tools, such as scan tools, to retrieve error codes from the vehicle’s computer system, which provides valuable insights into malfunctioning components.

Advanced Techniques

For more intricate issues, advanced diagnostic techniques may be needed. These can include examining wiring connections for damage or corrosion, as poor connections can often result in ignition switch failure. Additionally, inspecting the ignition rotor for wear and replacing it if necessary can prevent further complications caused by contact surface deterioration.

Hey, I’m Jack. Your blog is a game-changer! The content is insightful, well-researched, and always relevant. Great job!

Somebody essentially lend a hand to make significantly posts I might state That is the very first time I frequented your web page and up to now I surprised with the research you made to create this particular put up amazing Excellent job