Introduction to Dampers in Vehicle Suspension System

Dampers in Suspension System is a revolutionary way to improve the performance of your vehicle. Dampers are used to absorb vibration in different types of machines. The dampers are held in position by means of main springs. In a vehicle suspension system, springs alone are not satisfactory and sufficient. It must be remembered that the spring characteristics must be a compromise between flexibility and stiffness.

Spring must be flexible so that it can absorb road shocks. But if it is too flexible, it will flex and rebound excessively and repeatedly, giving a rough ride. A stiff spring will not flex and rebound so much after a bump has been passed. But, it will give a hard ride because it will transmit too much road shock to the vehicle. In practice, by using a relatively flexible or soft spring, and a damper, a satisfactory smooth ride can be achieved.

In a bumpy road and especially on a curve, the oscillations of the vehicle frame might become serious enough to cause the driver to lose control of the vehicle. The damper dampens out the spring oscillations quickly once the wheel has passed the hole or bump in the road. The damper is also called shock absorbed by many.

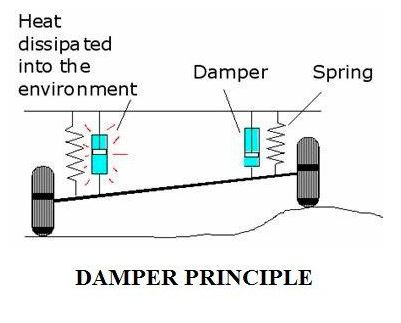

The spring energy is converted to heat which is dissipated partly by the friction of the system, but mostly by the dampers.

What is a Dampers in Suspension System?

Dampers are nothing but a piston in a cylinder filled with oil or gas. The damper’s function is to restrain undesirable bounce of the sprung vehicle mass and to restrain the wheel assembly from losing ground contact by being excited at its natural frequency.

If a compressed spring is released, it will continue to oscillate back and forth through several gradually diminishing cycles until all the energy is dissipated. This process could provide a very disturbing and dumpy ride. A properly tuned damper will allow a compressed spring, when released, to extend slightly beyond its natural length or shape, then return to rest. This is called critical damping.

Types of Suspension Dampers

There are different types of suspension dampers used in automotive applications. In this section, we will discuss the most common types of suspension dampers.

Piston Dampers

Piston dampers, also known as hydraulic dampers, are the most common type of dampers used in suspension systems. They work by forcing oil through a small orifice to create resistance to motion. The resistance generated by the piston damper is proportional to the speed of the suspension movement. Piston dampers are reliable, durable, and cost-effective.

Gas-filled Dampers

Gas-filled dampers, also known as gas shocks or gas struts, use pressurized gas to create resistance to motion. They work by using a piston to compress the gas inside a cylinder. The resistance generated by a gas-filled damper is proportional to the speed of the suspension movement. Gas-filled dampers are more expensive than piston dampers but offer better performance and handling.

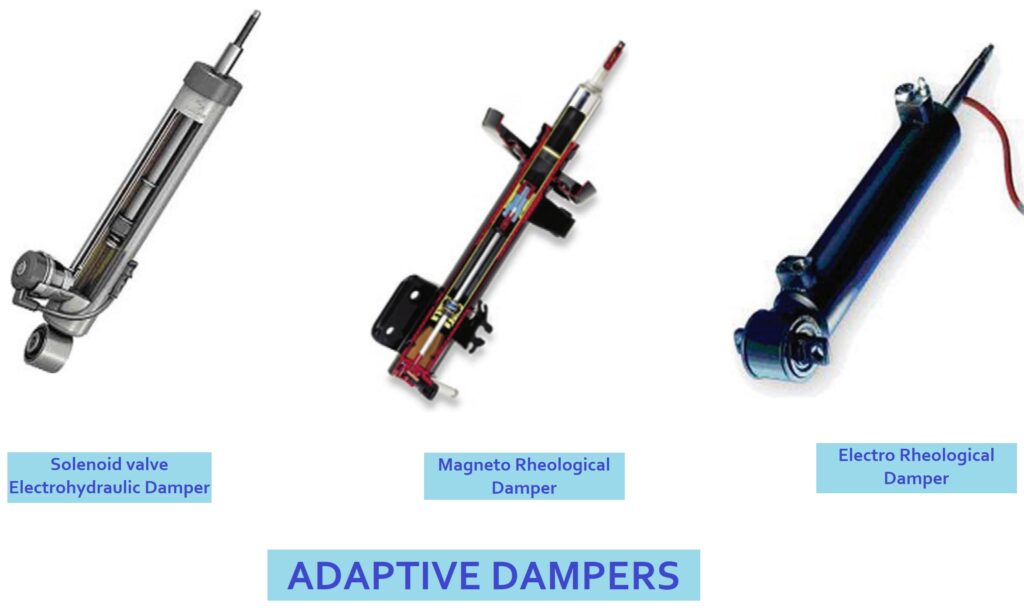

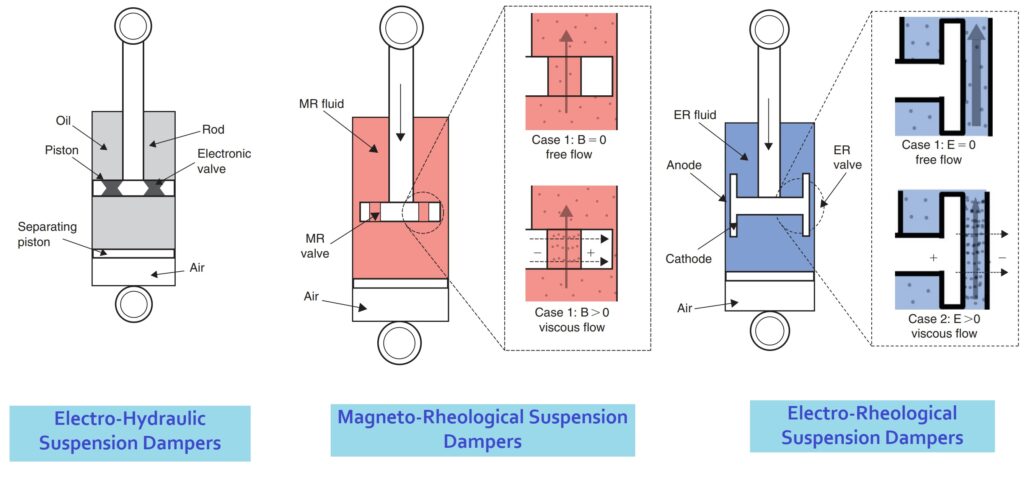

Adaptive Dampers

Adaptive dampers, also known as adjustable dampers or electronic dampers, use electronic sensors and controllers to adjust the damping force in real time. They work by monitoring the suspension movement and adjusting the damping force to optimize ride comfort and handling. Adaptive dampers are the most advanced type of dampers and offer superior performance and handling. However, they are also the most expensive.

In summary, there are different types of suspension dampers available, each with its own advantages and disadvantages. Piston dampers are the most common and cost-effective, while gas-filled dampers offer better performance and handling. Adaptive dampers are the most advanced and offer superior performance but are also the most expensive. The choice of suspension damper depends on the specific application and the desired performance characteristics.

Critical Damping

In most applications, critical damping is far too severe and the best damping for comfort and adequate wheel control falls between 15 and 50 percent of the critical value, depending on the inherent system friction and the required ride qualities.

The typical function of the damper in a modern car is to reduce the amplitude of the deflection over a bump to about a fifth of its initial value, within two cycles of oscillations, at the natural frequency of the system.

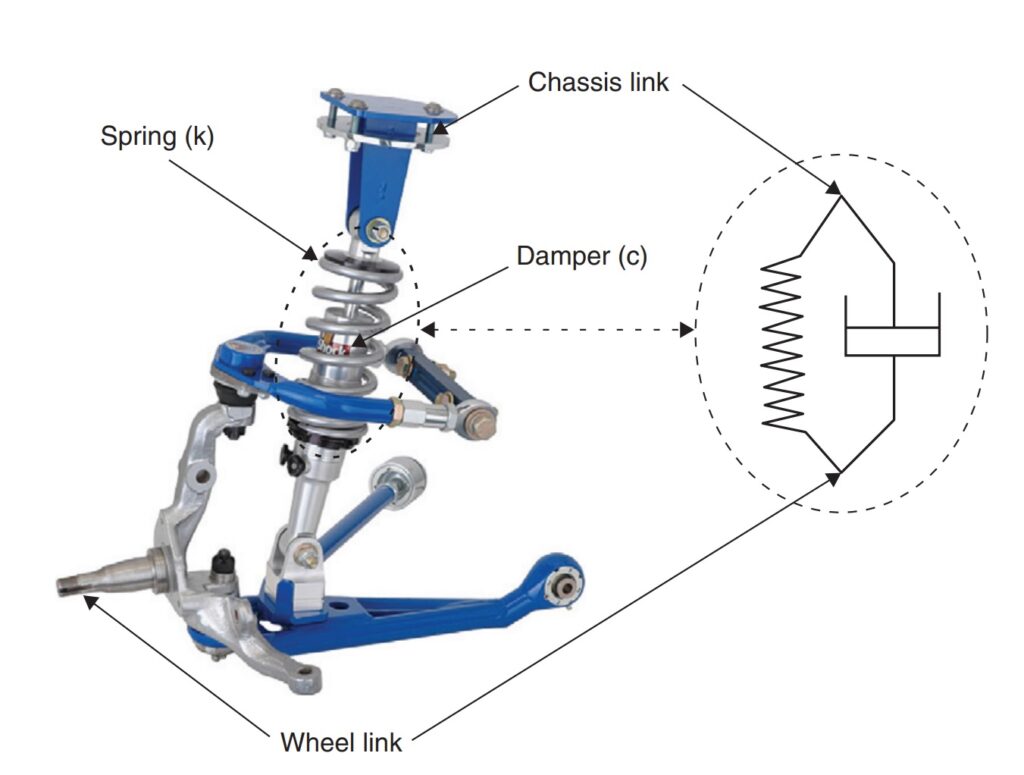

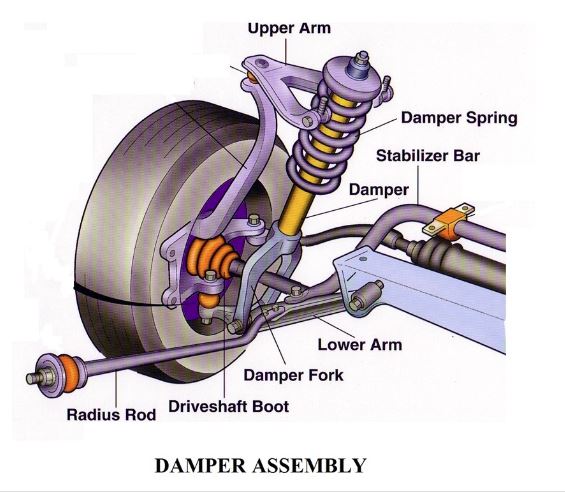

The independent front suspension assembly with a damper in position can be seen with the arrangements can be seen in this picture.

Adaptive Suspension Dampers

There are many types of shock absorbers, operating on friction, on compressed air, and hydraulically. The hydraulic shock absorber is the only type in common use at present. The hydraulic shock absorber contains a fluid that is forced through restricting orifices as the shock absorber is operated by spring flexure. The resistance to the movement of the fluid through the restricting orifices from one compartment to the other compartment in the shock absorber imposes a drag on spring movement. This effect quickly dampens spring oscillations.

Understanding Suspension System Dampers

How do Dampers in Suspension System Work?

Suspension system dampers are devices that help to control the movement of the vehicle’s suspension system. They work by reducing the amount of energy that is transferred between the suspension system’s springs and the vehicle’s body. This is done by converting the kinetic energy of the suspension’s movement into thermal energy, which is then dissipated into the atmosphere.

Dampers in suspension systems are made up of two main components: a piston and a cylinder. The piston is attached to the suspension system’s moving parts, while the cylinder is attached to the vehicle’s body. As the suspension system moves, the piston moves inside the cylinder, compressing the hydraulic fluid that is contained inside. This compression creates resistance, which slows down the movement of the suspension system and reduces the amount of energy that is transferred to the vehicle’s body.

Role of Dampers in Suspension System

The role of dampers in a suspension system is to control the movement of the vehicle’s body and improve its handling characteristics. Without dampers, the vehicle’s body would continue to bounce up and down after hitting a bump, making it difficult to control. Dampers help to prevent this by reducing the amount of energy that is transferred to the vehicle’s body, allowing it to remain stable and in control.

There are several different types of suspension system dampers, including hydraulic, gas, and electronic dampers. Each type has its own unique characteristics and advantages, depending on the application. For example, hydraulic dampers are commonly used in passenger cars because they provide a good balance between comfort and handling, while gas dampers are often used in high-performance vehicles because they offer better control and more precise handling.

In conclusion, understanding the role of dampers in suspension systems is important for anyone who wants to improve their vehicle’s handling and performance. By controlling the movement of the suspension system and reducing the amount of energy that is transferred to the vehicle’s body, dampers help to make the vehicle more stable and easier to control.

Types and Performance of Dampers

Types of Suspension Dampers

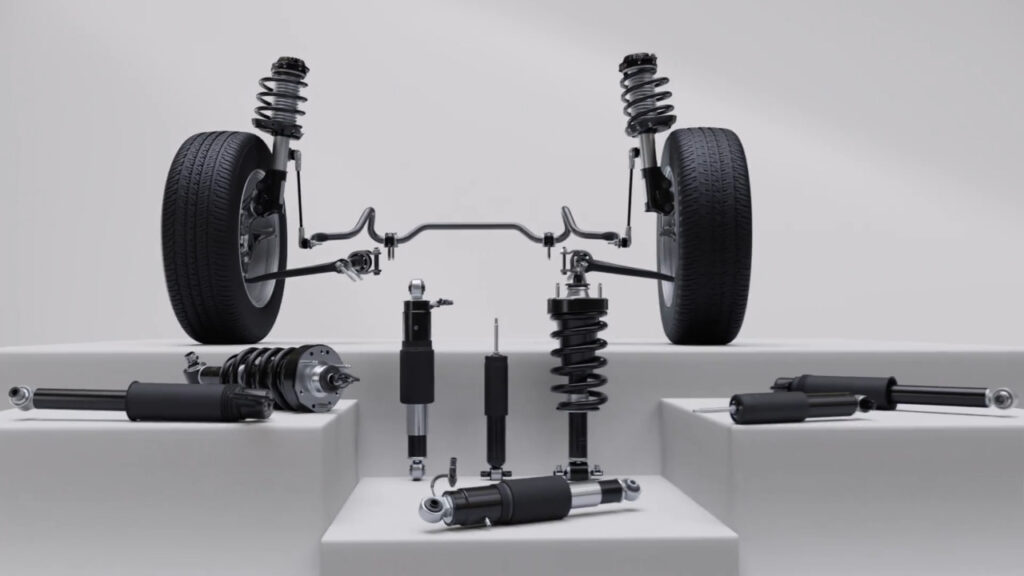

Suspension dampers are an essential component of a vehicle’s suspension system, and they play a crucial role in ensuring a smooth and comfortable ride. There are several types of suspension dampers available, each with its unique characteristics and benefits.

Here are some of the most common types of suspension dampers:

| Type of Dampers | Description |

|---|---|

| Twin-Tube | The most common type of damper, consists of two tubes, an inner and an outer tube. The inner tube houses the piston and oil, while the outer tube provides additional support. |

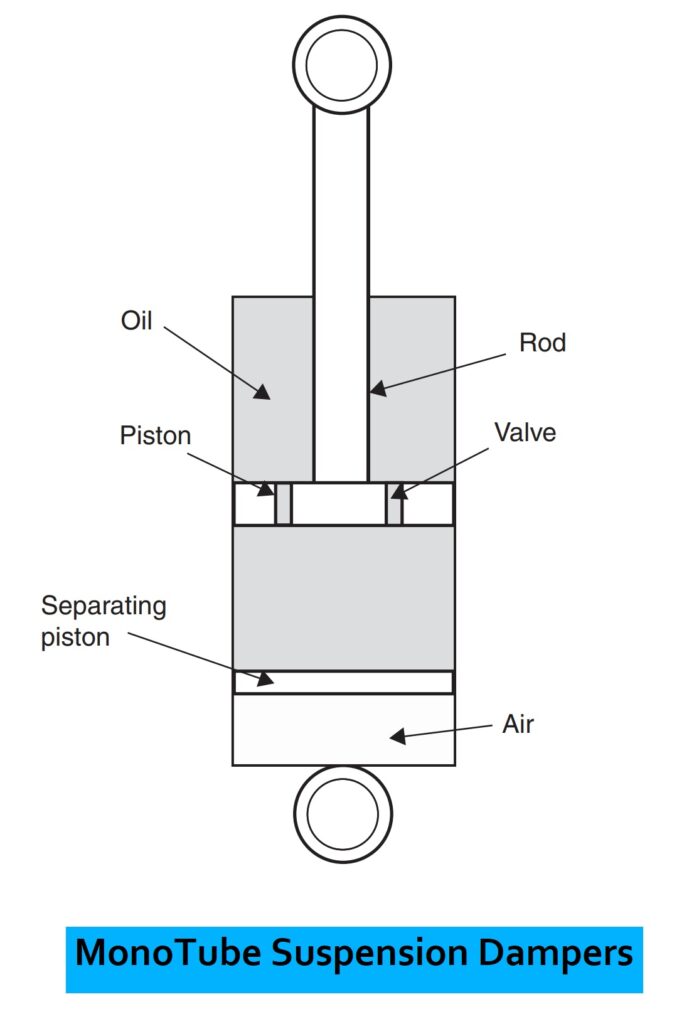

| Mono-Tube | A single-tube damper with a larger diameter than the twin-tube, which provides better heat dissipation and improved performance. |

| Coilover | A combination of a damper and a spring, which allows for more adjustability and customization. |

| Air | Uses compressed air to adjust the damping force, providing a smoother ride and improved handling. |

| Magnetic | Uses an electromagnetic field to adjust the damping force, providing improved performance and adjustability. |

Performance of Suspension Dampers

The performance of suspension dampers is critical to a vehicle’s overall handling, stability, and comfort. The damping force provided by the dampers helps to control the movement of the vehicle’s suspension, reducing oscillation and ensuring a smooth ride.

Here are some of the key performance factors to consider when selecting suspension dampers:

- Damping Force: The force required to move the piston through the oil. A higher damping force provides better stability and handling but may result in a harsher ride.

- Rebound and Compression: The rate at which the damper compresses and rebounds. A well-tuned damper will provide smooth and controlled compression and rebound.

- Adjustability: The ability to adjust the damping force to suit different driving conditions and preferences.

- Heat Dissipation: The ability of the damper to dissipate heat generated during operation, which can affect performance and longevity.

Overall, selecting the right suspension dampers is crucial to achieving optimal vehicle performance and ride comfort. By understanding the different types of dampers and their performance characteristics, you can make an informed decision when selecting the best damper for your vehicle.

Benefits and Importance of Dampers

Benefits of Dampers in Suspension Systems

Dampers are an essential component of a suspension system that provides a smooth ride and handling characteristics to a vehicle. The primary benefit of dampers is their ability to control the movement of the suspension system. By doing so, they help to reduce the amount of vibration and impact that is transmitted to the vehicle’s body, which improves ride comfort and reduces driver fatigue.

In addition to providing a comfortable ride, dampers also play a critical role in improving the handling and stability of a vehicle. They help to control the body roll of the vehicle during cornering and provide better traction by keeping the wheels in contact with the road surface. This leads to improved safety and overall performance of the vehicle.

Importance of Suspension Dampers

The importance of suspension dampers cannot be overstated. They are a critical component of a vehicle’s suspension system, and without them, the vehicle would be virtually undrivable. Dampers help to absorb the energy generated by the movement of the suspension system, which would otherwise be transferred to the vehicle’s body and cause discomfort to the occupants.

Suspension dampers also play a crucial role in preventing the suspension system from oscillating or bouncing after hitting a bump or pothole. Without dampers, the suspension system would continue to oscillate, leading to a loss of control and stability, which could result in an accident.

Moreover, dampers help to improve the lifespan of other suspension components such as springs, tires, and ball joints. By reducing the amount of shock and vibration that is transferred to these components, dampers help to minimize wear and tear, which leads to longer component life and lower maintenance costs.

In conclusion, dampers are an essential component of a vehicle’s suspension system that provides a comfortable ride, improves handling and stability, and increases the lifespan of other suspension components. Without dampers, a vehicle would be virtually undrivable, and its safety and performance would be compromised.

Issues and Troubleshooting

Common Issues with Suspension Dampers

Suspension dampers are critical components of the vehicle suspension system, and they play a crucial role in ensuring a smooth and comfortable ride. However, like any other mechanical component, they are prone to wear and tear, and this can lead to various issues. Some of the common issues with suspension dampers include:

- Leaking Oil: One of the most common issues with suspension dampers is oil leakage. This can happen due to worn-out seals or damaged piston rods. Leaking oil can cause the damper to lose its damping effect, leading to a bouncy ride and reduced stability.

- Excessive Bouncing: Another common issue with suspension dampers is excessive bouncing. This can happen due to worn-out or damaged dampers that are unable to absorb the shocks and vibrations from the road. Excessive bouncing can lead to reduced stability, poor handling, and increased wear and tear on other suspension components.

- Uneven Tire Wear: Worn-out or damaged suspension dampers can also cause uneven tire wear. This happens because the dampers are unable to keep the tires in contact with the road surface, leading to uneven wear patterns.

Troubleshooting Suspension Dampers

If you are experiencing any of the issues mentioned above, it is essential to troubleshoot the suspension dampers to identify the root cause of the problem. Here are some troubleshooting steps that you can follow:

- Visual Inspection: The first step in troubleshooting suspension dampers is to perform a visual inspection. Check for any signs of oil leakage, physical damage, or wear and tear. If you notice any of these issues, it is a sign that the dampers need to be replaced.

- Road Test: The next step is to perform a road test. This will help you identify any issues with the ride quality, stability, and handling of the vehicle. If you notice any excessive bouncing, reduced stability, or poor handling, it is a sign that the dampers are not functioning correctly.

- Compression Test: If you suspect that the suspension dampers are not functioning correctly, you can perform a compression test. This involves compressing the damper and checking the resistance. If the resistance is too low or too high, it is a sign that the damper needs to be replaced.

In conclusion, suspension dampers are critical components of the vehicle suspension system, and they play a crucial role in ensuring a smooth and comfortable ride. However, they are prone to wear and tear, and this can lead to various issues. By following the troubleshooting steps mentioned above, you can identify and address any issues with suspension dampers, ensuring optimal vehicle performance and safety.

Dampers vs Springs in Suspension System

When it comes to vehicle suspension systems, two crucial components are dampers and springs. While both are important, they serve different functions and have unique characteristics. In this section, we will explore the differences between dampers and springs in a suspension system.

Springs in Suspension System

Springs are the primary load-bearing component of a suspension system. They store and release energy as the vehicle moves over rough terrain. The primary function of a spring is to maintain the ride height of the vehicle and absorb the energy from bumps and vibrations.

Springs come in various types, including coil springs, leaf springs, and torsion bars. Coil springs are the most common type of spring used in modern suspension systems. They are made of steel and provide a smooth ride by compressing and expanding as the vehicle moves over uneven terrain.

Dampers in Suspension System

Dampers, also known as shock absorbers, are designed to control the motion of the spring. They work by converting the kinetic energy from the spring into heat, which is then dissipated into the atmosphere. Dampers help to maintain tire contact with the road surface, which is crucial for vehicle handling and stability.

Dampers come in various types, including hydraulic, gas, and electric. Hydraulic dampers are the most common type of damper used in modern suspension systems. They work by forcing hydraulic fluid through a piston, which creates resistance and slows down the motion of the spring.

Dampers vs Springs in Suspension System

In a suspension system, springs and dampers work together to provide a smooth and controlled ride. While springs absorb the energy from bumps and vibrations, dampers control the motion of the spring and prevent the vehicle from bouncing excessively.

The table below summarizes the key differences between dampers and springs in a suspension system:

| Component | Function | Characteristics |

|---|---|---|

| Springs | Load-bearing | Store and release energy, maintain ride height, absorb energy from bumps and vibrations |

| Dampers | Motion control | Convert kinetic energy into heat, maintain tire contact with the road surface, prevent excessive bouncing |

In summary, both dampers and springs are essential components of a suspension system. While springs absorb the energy from bumps and vibrations, dampers control the motion of the spring and maintain tire contact with the road surface. Understanding the differences between dampers and springs is crucial for maintaining optimal vehicle performance.

Maintenance and Upgrading of Suspension Dampers

Maintenance Tips for Suspension Dampers

Regular maintenance of suspension dampers is crucial to ensure optimal vehicle performance and safety. Here are some tips to keep your suspension dampers in top condition:

| Maintenance Tips for Suspension Dampers |

|---|

| * Regularly inspect your suspension dampers for signs of wear and tear, such as leaks, cracks, or damage to the piston rod. |

| * Replace your suspension dampers if they show any signs of damage or wear and tear. |

| * Check your suspension system alignment and tire pressure regularly to prevent excessive wear on your suspension dampers. |

| * Avoid driving over rough terrain or potholes at high speeds, as this can cause damage to your suspension dampers. |

| * Use high-quality suspension dampers that are designed for your specific vehicle make and model. |

Following these maintenance tips will help keep your suspension dampers in good condition and ensure optimal vehicle performance.

Upgrading Suspension Dampers

Upgrading your suspension dampers can significantly improve your vehicle’s handling, stability, and overall performance. When upgrading your suspension dampers, consider the following factors:

| Upgrading Suspension Dampers |

|---|

| * Choose suspension dampers that are specifically designed for your vehicle make and model. |

| * Consider the type of driving you do and choose suspension dampers that are designed for your driving style. For example, if you do a lot of off-road driving, consider upgrading to heavy-duty suspension dampers. |

| * Look for suspension dampers that offer adjustable damping settings, as this can allow you to fine-tune your vehicle’s handling and performance. |

| * Consider upgrading other components of your suspension system, such as springs and sway bars, to ensure optimal performance. |

Upgrading your suspension dampers can be a significant investment, but it can also greatly improve your vehicle’s performance and handling. Make sure to choose high-quality suspension dampers that are designed for your specific vehicle and driving style to ensure optimal results.

By following these maintenance tips and upgrading your suspension dampers when necessary, you can ensure optimal vehicle performance and safety.

Future and Innovations

Future of Suspension Dampers

As technology advances, the future of suspension dampers looks bright. We can expect to see more efficient, durable, and adaptable dampers that can handle a wide range of driving conditions. In the future, we can expect dampers that can adjust to different road surfaces and driving styles, providing a more comfortable and safe ride for passengers.

One of the most exciting developments in the future of suspension dampers is the use of advanced materials. We can expect to see dampers made from lightweight and durable materials that can withstand extreme temperatures and pressures. These materials will help reduce the weight of the vehicle, improve fuel efficiency, and provide better handling.

Another area of focus for the future of suspension dampers is the integration of electronic controls. We can expect to see more advanced electronic systems that can adjust the damping force in real time based on road conditions and driver inputs. These systems will help improve the overall performance of the vehicle and provide a more comfortable and safe ride.

Innovations in Suspension Dampers

In recent years, there have been several innovations in suspension dampers that have improved the performance and reliability of these components. One of the most significant innovations is the use of magnetorheological (MR) fluid dampers. MR fluid dampers use a special fluid that can change its viscosity in response to an external magnetic field. This allows the damping force to be adjusted in real time based on road conditions and driver inputs.

Another innovation in suspension dampers is the use of air suspension systems. Air suspension systems use compressed air to adjust the ride height of the vehicle and provide a smoother ride. These systems are particularly useful for large vehicles such as trucks and buses.

Finally, advancements in suspension dampers have also been made through the use of advanced manufacturing techniques. For example, some manufacturers are now using 3D printing to produce complex damper components that are lighter, stronger, and more durable than traditional components.

| Entity | Description |

|---|---|

| Future of Suspension Dampers | Expectation of more efficient, durable, and adaptable dampers, advanced materials, and integration of electronic controls. |

| Innovations in Suspension Dampers | Use of magnetorheological (MR) fluid dampers, air suspension systems, and advanced manufacturing techniques. |

| Advancements in Suspension Dampers | Improved performance and reliability of suspension dampers. |

Frequently Asked Questions

What is the function of a damper in the vehicle suspension system?

Dampers, also known as shock absorbers, are an essential component of the vehicle suspension system. Their primary function is to control the movement of the suspension system, preventing the vehicle from bouncing excessively after hitting a bump or pothole. Dampers work by converting the kinetic energy of the suspension movement into heat energy, which is then dissipated into the surrounding air.

How do dampers affect handling?

Dampers play a crucial role in the handling of a vehicle. They help to keep the wheels in contact with the road, ensuring that the vehicle remains stable and predictable. Without dampers, the vehicle would bounce excessively, causing the wheels to lose contact with the road. This would lead to a loss of control and could result in an accident.

How does the suspension system affect the performance of a vehicle?

The suspension system is critical to the overall performance of a vehicle. It affects the vehicle’s handling, ride comfort, and stability. A well-designed suspension system can improve the vehicle’s cornering ability, reduce body roll, and provide a smooth ride. On the other hand, a poorly designed suspension system can lead to a harsh ride, poor handling, and unstable driving conditions.

What are the types of dampers used in automobile suspension?

There are several types of dampers used in automobile suspension systems, including hydraulic, gas-charged, and electronic dampers. Hydraulic dampers are the most common and use a piston that moves through a hydraulic fluid to absorb shock. Gas-charged dampers use pressurized gas to improve damping performance, while electronic dampers use and computer-controlled valves to adjust damping rates in real time.

What is damper performance?

Damper performance is a measure of how well the damper is able to control the movement of the suspension system. A high-performance damper will be able to absorb shock quickly and effectively, providing a smooth ride and stable handling. On the other hand, a low-performance damper will be slow to react, leading to a harsh ride and poor handling.

Why is the warning light for suspension dampers important?

The warning light for suspension dampers is an essential safety feature in modern vehicles. It alerts the driver when there is a problem with the suspension system, allowing them to take corrective action before a serious accident occurs. If the warning light comes on, it is essential to have the suspension system inspected by a qualified mechanic as soon as possible.

| FAQ’s | Description |

|---|---|

| What is the function of a damper in the vehicle suspension system? | The function of a damper in the vehicle suspension system is to control the movement of the suspension system. |

| How do dampers affect handling? | Dampers play a crucial role in the handling of a vehicle by keeping the wheels in contact with the road. |

| How does the suspension system affect the performance of a vehicle? | The suspension system affects the vehicle’s handling, ride comfort, and stability. |

| What are the types of dampers used in automobile suspension? | The types of dampers used in automobile suspension systems include hydraulic, gas-charged, and electronic dampers. |

| What is damper performance? | Damper performance is a measure of how well the damper is able to control the movement of the suspension system. |

| Why is the warning light for suspension dampers important? | The warning light for suspension dampers is an essential safety feature in modern vehicles that alerts the driver when there is a problem with the suspension system. |