Introduction

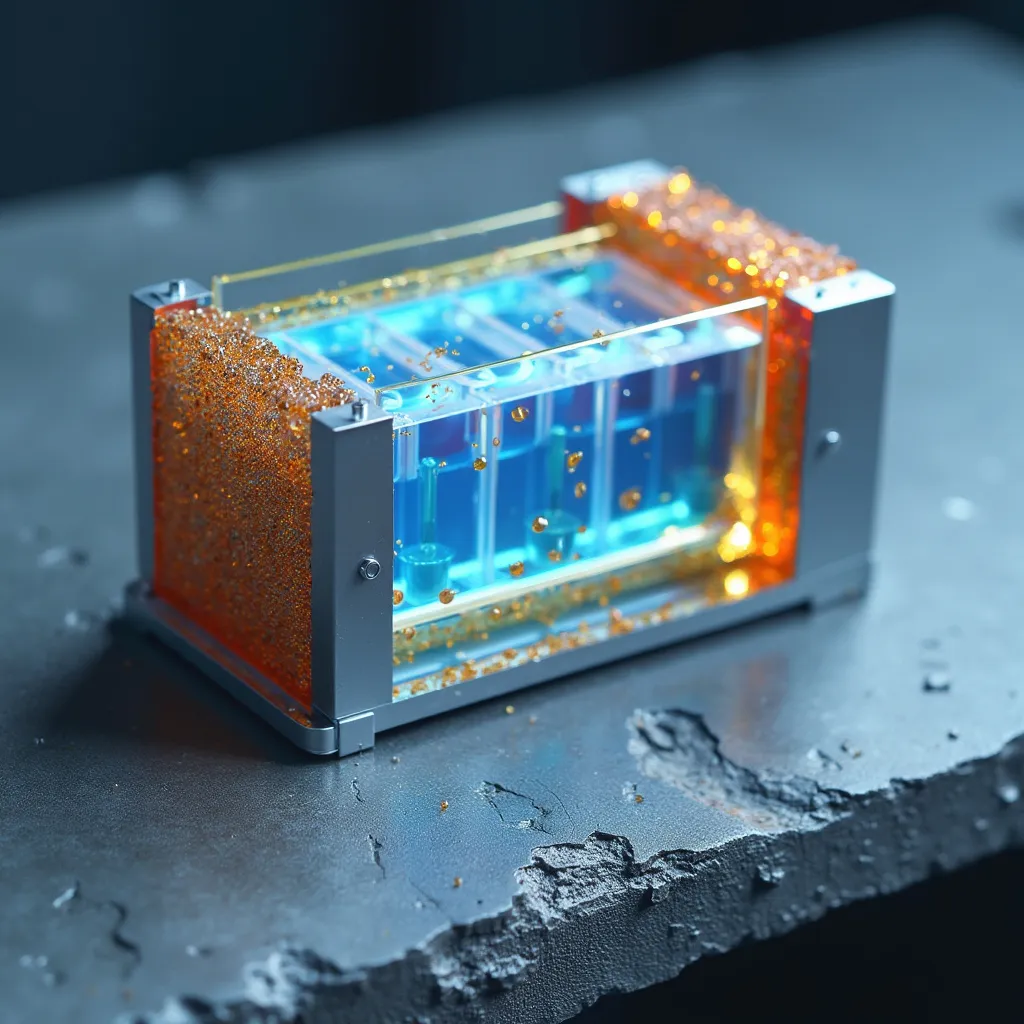

Direct-Ammonia Solid Oxide Fuel Cells (DA-SOFCs) are an innovative type of fuel cell that directly utilize ammonia as a fuel source, offering a promising solution for sustainable energy generation. Emerging from the evolution of solid oxide fuel cells (SOFCs), DA-SOFCs capitalize on ammonia’s potential as a carbon-free hydrogen carrier, which is crucial in the quest to reduce greenhouse gas emissions associated with traditional fossil fuels.

This technology is notable for its ability to improve efficiency and environmental outcomes, thereby attracting significant interest from both academic research and industry applications in recent years. The operation of DA-SOFCs involves the electrochemical conversion of ammonia into nitrogen and hydrogen, facilitating electricity generation while minimizing harmful emissions. This operational principle not only enhances the efficiency of the fuel cell but also allows for flexible fuel utilization without extensive reforming processes.

The potential applications of DA-SOFC technology span various sectors, including power generation, transportation, and industrial processes, reflecting its versatility in meeting energy needs sustainably. Despite their advantages, DA-SOFCs face challenges related to performance optimization, material durability, and commercial scalability. Researchers are focused on overcoming these hurdles, aiming to enhance the operational stability and longevity of these fuel cells.

Additionally, concerns surrounding ammonia’s environmental impact, particularly regarding nitrogen oxides (NOx) emissions, necessitate careful consideration in deployment strategies to fully realize the benefits of DA-SOFC technology. As global energy demands evolve, and with the push towards carbon neutrality intensifying, DA-SOFCs are increasingly positioned as a viable alternative in the clean energy landscape. Their successful integration could significantly contribute to cleaner power generation and a more sustainable energy future, making them a focal point in the ongoing research and development of advanced fuel cell technologies.

History

Early Developments in Fuel Cell Technology

The concept of fuel cells has its roots in the early 19th century, with the first working prototype created by Sir William Grove in 1839. Grove’s invention, known as the “gas battery,” utilized hydrogen and oxygen to produce electricity and water, laying the groundwork for future fuel cell technology. However, it wasn’t until the mid-20th century that significant advancements were made, particularly for space applications during the 1960s, when the U.S. space program adopted hydrogen-oxygen fuel cells for missions, including the Apollo program

.

Transition to Solid Oxide Fuel Cells

By the 1970s, research shifted towards solid oxide fuel cells (SOFCs) due to their higher efficiency and versatility compared to traditional liquid electrolyte systems. SOFCs employ a solid ceramic electrolyte to facilitate the electrochemical reaction, enabling operation at high temperatures and broad fuel flexibility. This shift marked a significant evolution in fuel cell technology, which paved the way for various applications, including stationary power generation and portable energy solutions.

Emergence of Direct-Ammonia Solid Oxide Fuel Cells (DA-SOFCs)

In the late 20th and early 21st centuries, researchers began exploring direct-ammonia solid oxide fuel cells (DA-SOFCs) as a promising alternative. Ammonia, being a carbon-free hydrogen carrier, presents a viable option for reducing greenhouse gas emissions associated with conventional fossil fuels. The advent of DA-SOFC technology capitalizes on the ability to directly utilize ammonia as fuel, simplifying the system and enhancing efficiency. This innovation attracted significant attention from both academia and industry as a potential game-changer in the pursuit of sustainable energy solutions.

Recent Advancements and Future Prospects

In recent years, there has been a resurgence of interest in DA-SOFCs driven by advances in materials science and engineering. Research initiatives focus on optimizing performance, durability, and operational stability of these fuel cells. As the world increasingly turns to renewable energy sources and strives for carbon neutrality, DA-SOFCs are positioned as a viable option in the energy landscape, potentially contributing to cleaner power generation in various applications ranging from industrial to residential.

Principle of Operation

Direct-Ammonia Solid Oxide Fuel Cells (DA-SOFCs) operate through a unique electrochemical process that directly utilizes ammonia as fuel. This system is characterized by several key operational principles that influence its efficiency and performance.

Electrochemical Reactions

The fundamental operation of DA-SOFCs involves the ionization of ammonia and its subsequent reactions at the electrodes. The ammonia is fed into the fuel cell where it is split into nitrogen and hydrogen through a process that occurs at the anode. The hydrogen then participates in electrochemical reactions, contributing to the production of electricity and water as by-products. The thermal neutral voltage is a critical parameter in this context, as operating at this voltage allows the fuel cell to maintain efficiency without excess heat generation, thereby preventing thermal degradation of cell components.

The overall reaction is:

NH3 + O2 → N2 + H2O + electricity

The thermal neutral voltage is the voltage at which the fuel cell operates without generating excess heat. Operating at this voltage is crucial to maintaining efficiency and preventing thermal degradation of the cell components.

Fuel-Rich Conditions

For optimal performance, DA-SOFCs often operate under fuel-rich conditions, characterized by an equivalence ratio greater than 1.0. This approach leads to an excess of ammonia in the fuel blend, which has been shown to mitigate NOx emissions and stabilize flame characteristics during combustion processes. A typical equivalence ratio, such as 1.2, signifies this fuel surplus, enhancing the overall efficiency and environmental benefits of the fuel cell.

Temperature Effects

Temperature plays a significant role in the performance of DA-SOFCs. Higher operational temperatures allow for better fuel utilization and enhanced ion conductivity, which is crucial for effective electrochemical reactions. However, maintaining an optimal temperature is essential, as fluctuations can negatively impact the reaction rates and overall performance of the cell. Research has indicated that the decrease in oxygen concentration within the cell is initially rapid but slows as reaction kinetics dictate, emphasizing the need for adequate oxygen supply to support high reaction rates.

Hydrogen Composition Influence

The efficiency of DA-SOFCs is also highly dependent on the composition of the gas mixture, particularly the hydrogen content. As hydrogen is a primary reactant, its concentration directly influences the energy density and output of the fuel cell. Thus, careful management of the gas composition is essential for maximizing performance and ensuring the stability of the fuel cell during operation.

Modular Design and Applications

One of the advantages of DA-SOFCs is their ability to be configured in a modular design, which enhances flexibility in installation and maintenance. This design approach facilitates the integration of DA-SOFC technology into various applications, including ship-based power systems, where compactness and efficiency are critical. The ability to generate hydrogen on-site further supports the commercialization of these fuel cells, addressing safety and efficiency challenges associated with hydrogen transport and storage.

Materials Used

The effectiveness of Direct-Ammonia Solid Oxide Fuel Cells (DA-SOFCs) is significantly influenced by the materials utilized in their construction, particularly the electrolyte and electrode materials. Various innovative materials have been developed to optimize performance and enhance the efficiency of these fuel cells.

Electrolyte Materials

Electrolytes in DA-SOFCs are crucial for ion conduction and overall cell performance. Traditionally, yttria-stabilized zirconia (YSZ) has been used due to its high ionic conductivity at elevated temperatures. However, recent advancements have introduced new classes of electrolyte materials that offer improved properties. Among these, ceria-doped electrolytes such as samaria-doped ceria (SDC) and gadolinium-doped ceria (GDC) have garnered interest for their enhanced ionic conductivity, particularly at lower temperatures (300-600 °C) compared to YSZ, which requires higher operational temperatures (1,000 °C) for optimal performance.

Furthermore, recent developments have focused on semiconductor-based electrolytes, such as those using apatite structures, which exhibit promising oxide ionic conductivity. The introduction of novel materials such as carbonates and composite structures has further expanded the range of options for efficient ionic conduction, allowing for the potential integration of low-temperature applications in DA-SOFCs.

Electrode Materials

Electrode materials in DA-SOFCs must efficiently facilitate the electrochemical reactions occurring at the anode and cathode. Perovskite oxides, known for their mixed ionic and electronic conductivity, are often employed in electrode applications. These materials, with the general formula ABO3, have unique structural properties that allow them to efficiently transfer charge under various operating conditions. Recent studies have indicated that the combination of p-type and n-type semiconductor materials can create heterojunctions that improve charge separation and transport at the electrode interfaces.

For example, the use of lanthanum strontium cobalt iron oxide (LSCF) as a cathode material, paired with a suitable anode material, can enhance the overall performance of the DA-SOFC by optimizing charge transfer during the redox reactions. Moreover, innovative approaches such as using carbon fiber composites for electrodes are being explored to reduce weight while maintaining structural integrity and performance under operational stresses. These advancements in materials not only aim to improve efficiency but also focus on enhancing durability and reducing degradation over time.

Advantages

Direct-Ammonia Solid Oxide Fuel Cells (DA-SOFCs) offer a range of advantages, particularly in terms of efficiency, environmental impact, and operational flexibility.

High Efficiency and Low Emissions

DA-SOFCs are known for their high efficiency in converting chemical energy into electrical energy, with operational efficiencies often exceeding those of traditional fuel cells. The use of ammonia as a fuel contributes to lower emissions of nitrogen oxides (NOx), particularly under specific combustion conditions. Studies indicate that increasing the fuel equivalence ratio can significantly reduce NOx emissions, leading to a decrease in both aquatic and terrestrial acidification. For instance, at an equivalence ratio of approximately 1.2, the emission levels reach a threshold where ammonia fuel options have a markedly lower environmental impact compared to conventional fuels.

Reduced Environmental Impact

The environmental advantages of DA-SOFCs are notable, especially when compared to other energy generation methods. The combination of ammonia with biogas, for example, results in lower impacts on ionizing radiation, ozone layer depletion, and aquatic ecotoxicity compared to nuclear-generated ammonia. Additionally, the DA-SOFC technology presents a lower environmental footprint regarding non-renewable energy usage, making it a more sustainable option in the long run.

Versatility and Adaptability

DA-SOFCs exhibit versatility in fuel usage, being capable of utilizing ammonia directly without the need for extensive reforming processes. This operational flexibility allows for on-site hydrogen generation, which is particularly advantageous for applications in maritime and portable power systems. The ability to operate at higher temperatures compared to proton exchange membrane fuel cells (PEMFCs) further enhances their adaptability, enabling efficient waste heat recovery and improved fuel utilization.

Economic Viability

The implementation of DA-SOFC technology may also yield economic benefits. The reduced reliance on precious metals for catalysts, as seen in some ammonia fuel cell designs, could lower production costs and improve the economic viability of hydrogen infrastructure. Additionally, advances in materials and manufacturing techniques are expected to enhance the durability and longevity of DA-SOFCs, resulting in lower lifecycle costs and improved return on investment.

Challenges

The development of Direct-Ammonia Solid Oxide Fuel Cells (DA-SOFCs) faces several significant challenges that must be addressed to enhance their performance and viability for commercial use.

Applications

Direct-ammonia solid oxide fuel cells (DA-SOFC) have emerged as a promising technology in various applications due to their unique ability to utilize ammonia directly as a fuel source. This section explores the diverse use cases and benefits of DA-SOFC systems.

Power Generation

The use of DA-SOFC in power generation is particularly noteworthy. Systems fueled by ammonia can deliver lower global warming impacts compared to their petroleum counterparts. Bicer and Dincer (2018a) reported that ammonia-fed power generation systems possess considerable advantages, although they also highlighted potential trade-offs in terms of higher acidification from NOx emissions. This indicates the need for careful consideration in deployment scenarios to optimize environmental benefits.

Transportation

DA-SOFC technology is being explored for use in transportation, particularly in vehicles powered by ammonia derived from renewable sources. Research indicates that internal combustion engine vehicles fueled by biomass-based ammonia can achieve lower carbon footprints compared to traditional gasoline or diesel engines, despite higher nitrogen footprints associated with ammonia usage. Moreover, life cycle assessments suggest that city transport systems utilizing ammonia from electrolytic processes powered by nuclear energy may offer significantly reduced global warming potentials.

Industrial Applications

In industrial settings, DA-SOFCs can play a crucial role in creating sustainable energy solutions. The integration of DA-SOFC with existing infrastructure can facilitate cleaner energy production while leveraging ammonia’s availability from renewable sources. Additionally, the adoption of ammonia as a fuel aligns with the growing trend towards reducing carbon footprints in manufacturing processes.

Energy Storage and Flexibility

With the increasing demand for flexible and sustainable energy sources, DA-SOFCs can act as energy storage systems. As the global energy landscape shifts towards renewables, the ability to convert ammonia back into electricity provides a reliable method for balancing supply and demand. This application can mitigate the challenges posed by intermittent renewable energy sources, thereby enhancing overall grid stability.

Future Prospects

The future of Direct-Ammonia Solid Oxide Fuel Cells (DA-SOFCs) holds significant potential, particularly as interest in alternative energy sources and sustainable technologies continues to grow. While there are notable challenges that remain, there are also promising opportunities that could catalyze advancements in this technology.

Opportunities

Investments in energy technologies have shown resilience, with over $1 trillion being invested across various tech trends in 2022 alone, indicating robust confidence in their long-term value potential. Within this landscape, DA-SOFCs are positioned to benefit from the growing emphasis on security, privacy, and resilience across industries. Moreover, as applied AI and advanced connectivity technologies mature, they could play a crucial role in optimizing DA-SOFC operations and efficiency. This integration of AI could lead to more effective management of fuel cells and enhance their scalability, potentially paving the way for widespread adoption.

Challenges

Despite the promising outlook, DA-SOFCs face several challenges that need to be addressed. The technology has not yet seen the level of application that other fuel cell types have achieved, and substantial research is required to overcome existing barriers to implementation. This includes addressing the complexities of ammonia as a fuel source, which presents unique technical hurdles related to efficiency and safety.

Future Recommendations

To fully harness the potential of DA-SOFCs, further investigations into their design and operational methodologies are essential. This includes exploring novel techniques that have not yet been employed within this specific technology. Additionally, fostering partnerships between industries, academia, and government could facilitate the research needed to drive innovation in DA-SOFCs.

As businesses increasingly prioritize sustainable energy solutions, the demand for efficient and effective fuel cell technologies is likely to grow, encouraging further investment and development in the DA-SOFC space. By focusing on these areas, stakeholders can position DA-SOFCs as a key player in the transition toward cleaner energy sources, ultimately contributing to global sustainability goals.