The fuel tank gravity feed system is a critical component in many petrol engines, playing a vital role in the efficient operation of carburetors. This article will explore the intricacies of gravity feed systems, their advantages and disadvantages, and how they impact engine performance. We’ll also discuss modern alternatives and provide practical tips for maintaining and optimizing these systems.

Understanding Fuel Tank Gravity Feed Systems

Gravity feed systems rely on the simple principle of gravity to deliver fuel from the tank to the carburetor. In this setup, the fuel tank is positioned higher than the carburetor, allowing fuel to flow naturally downward. This arrangement eliminates the need for a fuel pump, reducing complexity and potential points of failure.

How Fuel Tank Gravity Feed Works

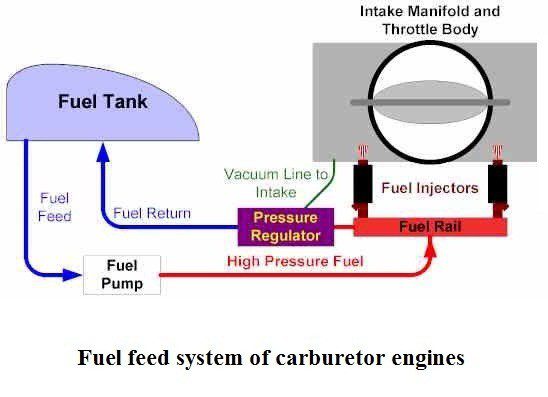

The fuel tank gravity feed system is a simple, yet effective, mechanism that relies on gravity to supply fuel to the carburetor. The system consists of a fuel tank, fuel pump, fuel filter, and fuel lines that connect the tank to the carburetor. When the engine is running, the fuel pump creates a vacuum that draws fuel from the tank, which is then filtered and supplied to the carburetor through the fuel lines. The carburetor, in turn, mixes the fuel with air to create a combustible mixture that powers the engine.

Components of a Gravity Feed System

Fuel Tank:

Typically located above the engine, often in the cowl or behind the firewall.

Fuel Lines:

Tubing that connects the fuel tank to the carburetor.

Fuel Filter:

Removes impurities from the fuel before it reaches the carburetor.

Carburetor:

Mixes fuel with air to create a combustible mixture for the engine. Carburetion in the carburetor is the process of measuring, mixing and supplying to a spark-ignition engine continuously a suitable combustible mixture of fuel and air. This mixture supply must be in accordance with the engine speed and load requirements. The carburetor supplies this mixture to an engine. The carburetor consists basically of a float chamber and a metering cum mixing chamber.

Fuel Tank Gravity Feed-In Carburetor

The preparation of the air-fuel mixture and its supply to the cylinders of the carburetor engine, the adjustment of its quality and quantity are accomplished by the fuel feed system. The feed system operation has a large effect on all the principal engine parameters. Therefore, necessary care must be taken to keep this system in proper working order during the engine use.

The system has a storage tank with a fuel level amount sensing element, fuel gauge, filter, and pump for supplying fuel from tank to carburetor. The fuel tank cap is vented. The atmospheric air enters the carburetor via an air filter which acts at the same time as an intake silencer. From the carburetor, the fuel-air mixture is supplied to the cylinder via the intake duct.

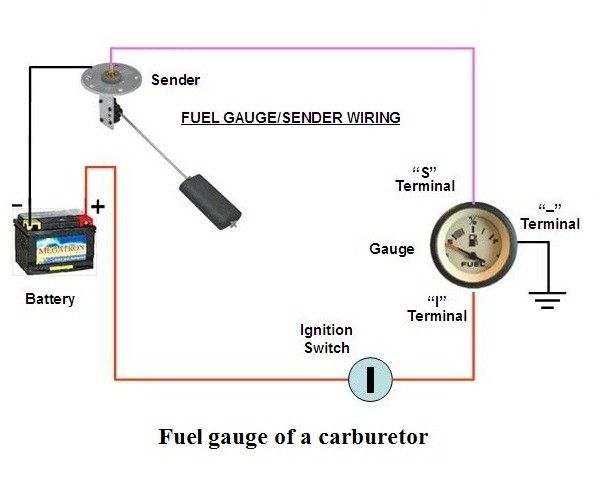

Fuel gauge

An electric gauge with balanced coils is used in many cars for indicating the quantity of fuel available in the fuel tank. The gauge is mounted on the instrument panel in front of the driver. This type of electric fuel gauge consists of two units a dash unit and a tank unit.

Fuel strainer

Some of the fuel tanks include a fuel filter at their exit or a sump at the bottom, to collect dirt and water and prevent them from reaching the pump and carburetor. Some tanks are provided with a drain plug on the bottom for emptying the tank. Fuel tanks are often provided with vertical baffles to prevent the surging of the fuel. An additional fuel strainer is usually placed in the fuel line either before the pump as shown in the picture or after the pump to filter gasoline before it enters the float chamber. The unit serves to catch any water or foreign particles that were not filtered out previously, in the fuel tank filter unit.

One type of filter is shown in the picture. The fuel that enters the glass bowl, passes through a ceramic filter to reach the inside section that is connected with the exit. The water and sediment are collected in the bowl which is made removable for cleaning. Some engines use a disposable fuel filter in the fuel feed system. The entire unit may be replaced whenever it becomes inoperative, simply by loosening snap clamps.

Advantages of Gravity Feed Systems

- Simplicity: With fewer moving parts, these systems are less prone to mechanical failures.

- Cost-Effective: The absence of a fuel pump reduces manufacturing and maintenance costs.

- Reliability: Gravity is a constant force, ensuring consistent fuel delivery in various conditions.

Disadvantages and Limitations

- Height Restrictions: The fuel tank must be positioned above the carburetor, limiting design flexibility.

- Fuel Pressure Variations: Pressure can fluctuate as the fuel level in the tank changes.

- Performance Limitations: May not provide sufficient fuel flow for high-performance applications.

Impact on Engine Performance

The gravity feed system directly influences engine performance through its fuel delivery mechanism. Proper functioning ensures a steady supply of fuel, which is crucial for maintaining optimal air-fuel ratios and engine efficiency.

Fuel Delivery Consistency

Gravity feed systems can provide consistent fuel delivery under normal operating conditions. However, factors such as fuel level, engine load, and vehicle orientation can affect fuel flow, potentially impacting performance.

Fuel Pressure Considerations

Unlike pump-fed systems, gravity feed setups rely solely on the weight of the fuel column to generate pressure. This can lead to variations in fuel pressure, especially as the tank empties, potentially affecting engine performance at different fuel levels.

Modern Alternatives to Gravity Feed Systems

While gravity feed systems remain common in small engines and some classic vehicles, modern automotive design has largely shifted towards electric fuel pumps. These pumps offer several advantages:

- Consistent Fuel Pressure: Electric pumps maintain steady pressure regardless of fuel level or vehicle orientation.

- Design Flexibility: Fuel tanks can be positioned anywhere in the vehicle.

- Higher Performance Capability: Can deliver higher fuel flow rates for more powerful engines.

Maintaining and Optimizing Gravity Feed Systems

Proper maintenance is crucial for ensuring the efficiency and longevity of gravity feed systems. Here are some key considerations:

Regular Inspections

- Check fuel lines for cracks, leaks, or degradation.

- Inspect the fuel tank for corrosion or damage.

- Examine the carburetor for proper function and cleanliness.

Fuel Filter Maintenance

Regularly replace the fuel filter to prevent clogging and ensure clean fuel reaches the carburetor. A clogged filter can significantly restrict fuel flow, impacting engine performance.

Carburetor Tuning

Proper carburetor adjustment is crucial for optimal performance with gravity feed systems. Consider factors such as:

- Float level adjustment

- Jet sizing

- Accelerator pump function

Fuel Quality

Use high-quality fuel and consider fuel stabilizers for long-term storage to prevent degradation and carburetor clogging.

Troubleshooting Common Issues

- Fuel Starvation: If the engine sputters or dies at high RPMs, check for restrictions in the fuel line or a clogged filter.

- Flooding: Excessive fuel in the carburetor can indicate a stuck float or improper float level adjustment.

- Inconsistent Performance: This may be due to variations in fuel pressure as the tank level changes.

Several common issues can affect the fuel tank gravity feed system, including:

- Clogged fuel filters: Clogged fuel filters can restrict fuel flow, leading to poor engine performance and decreased fuel efficiency.

- Faulty fuel pumps: A faulty fuel pump can fail to create the necessary vacuum, leading to fuel starvation and poor engine performance.

- Leaks in the fuel system: Leaks in the fuel system can cause fuel to escape, leading to poor engine performance, decreased fuel efficiency, and safety risks.

Optimizing Fuel Tank Gravity Feed for Improved Engine Performance

To optimize the fuel tank gravity feed system for improved engine performance, follow these actionable tips:

- Regularly clean and replace fuel filters: Regularly cleaning and replacing fuel filters can ensure unrestricted fuel flow and improved engine performance.

- Check and maintain fuel pump performance: Regularly checking and maintaining fuel pump performance can ensure that the necessary vacuum is created, preventing fuel starvation and poor engine performance.

- Inspect and repair fuel system leaks: Regularly inspecting and repairing fuel system leaks can prevent fuel escape, ensuring improved engine performance and decreased safety risks.

Conclusion

In conclusion, the fuel tank gravity feed system is a critical component of many petrol engines, playing a vital role in the efficient operation of carburetors. While these systems offer simplicity, cost-effectiveness, and reliability, they also have limitations and disadvantages. By understanding the intricacies of gravity feed systems, their advantages and disadvantages, and how they impact engine performance, vehicle owners and enthusiasts can make informed decisions about maintenance, optimization, and potential upgrades.