Introduction

Ignition Switching and Triggering refers to the mechanisms and technologies used to initiate the combustion process in internal combustion engines, as well as the electrical systems responsible for controlling this process. These systems are essential for the reliable operation of automobiles and have undergone significant evolution from early mechanical designs to modern electronic solutions. Notable figures, such as Charles F. Kettering, played pivotal roles in advancing ignition technology, which has been a key factor in improving engine performance and reducing emissions in the automotive industry.

The evolution of ignition systems is marked by several key developments, including the transition from conventional breaker-point ignition to electronic and distributor-less systems. Each type offers distinct advantages in terms of reliability, maintenance, and performance. For instance, while conventional systems require frequent maintenance, electronic ignition systems significantly reduce these needs and improve fuel efficiency. As a result, modern ignition systems are designed to meet the increasing demands of both traditional and electric vehicles, reflecting broader trends in automotive technology.

In addition to automotive applications, ignition switching and triggering systems are crucial in safety mechanisms such as ignition interlock devices (IIDs), which are designed to prevent impaired driving. IIDs require a breath sample from the driver before allowing the vehicle to start, thereby reducing alcohol-related crashes and enhancing road safety. Research has shown that states with robust IID laws experience lower rates of alcohol-related fatalities compared to those without such regulations.

This illustrates the growing importance of ignition technology in both performance and safety contexts. The ongoing development of ignition systems is influenced by technological advancements, regulatory changes, and market trends. As the automotive landscape shifts towards greater electrification and connectivity, manufacturers are adapting ignition technologies to align with new standards and consumer preferences, making it a dynamic area of innovation within the industry.

History

Early Developments in Ignition Systems

The history of ignition systems can be traced back to the early 20th century when the first points-based systems were developed. These systems utilized mechanical contact points that regulated the flow of current to the ignition coil, generating the spark needed to ignite the fuel-air mixture in internal combustion engines. This mechanical method played a crucial role in the operation of early automobiles, ensuring that engines could start reliably.

The Advent of Electric Ignition

The transition from mechanical points to electric ignition systems marked a significant advancement in automotive technology. Charles F. Kettering, an influential inventor, played a pivotal role in this evolution by developing the electric self-starter and ignition systems in the early 1900s. His innovations greatly improved the convenience and reliability of starting engines, effectively replacing the labor-intensive hand-cranking method. Kettering’s work laid the foundation for modern ignition systems and has had a lasting impact on automotive engineering.

The Rise of Conventional Coil Systems

By the mid-20th century, the introduction of conventional coil ignition systems became prevalent. These systems offered increased efficiency and reliability over their predecessors. The ignition coil’s ability to produce a high-voltage spark allowed for better combustion and performance of engines, particularly as automobile designs became more sophisticated and powerful.

Technological Advancements

With advancements in technology, ignition systems continued to evolve. The incorporation of electronic control units (ECUs) into ignition systems allowed for more precise control of ignition timing, contributing to improved fuel efficiency and reduced emissions. As automotive technology progressed, systems also began to include features like variable ignition timing and improved diagnostics, which further enhanced their performance and reliability.

Modern Innovations

In recent years, the integration of digital technologies and real-time data analytics has transformed ignition systems. Manufacturers are now developing systems that incorporate telematics and smartphone compatibility, leading to enhanced user accessibility and better data management. This shift towards digital solutions has not only improved the monitoring and compliance aspects of ignition systems but has also driven competition and innovation within the industry.

Types of Ignition Switching

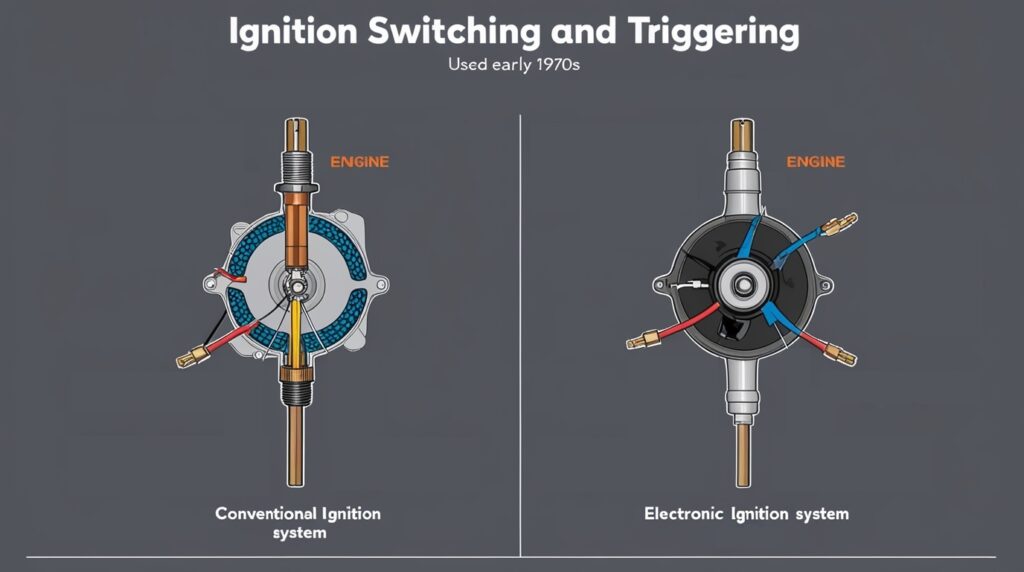

Automotive ignition systems have evolved significantly over the years, with various types designed to meet different performance and reliability needs. Generally, these systems can be classified into three main categories: conventional breaker-point ignition, electronic ignition, and distributor-less ignition systems.

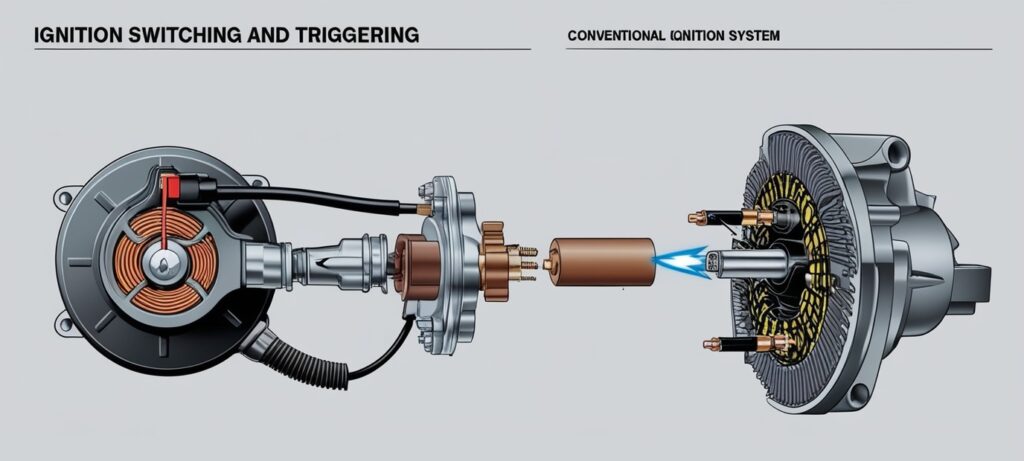

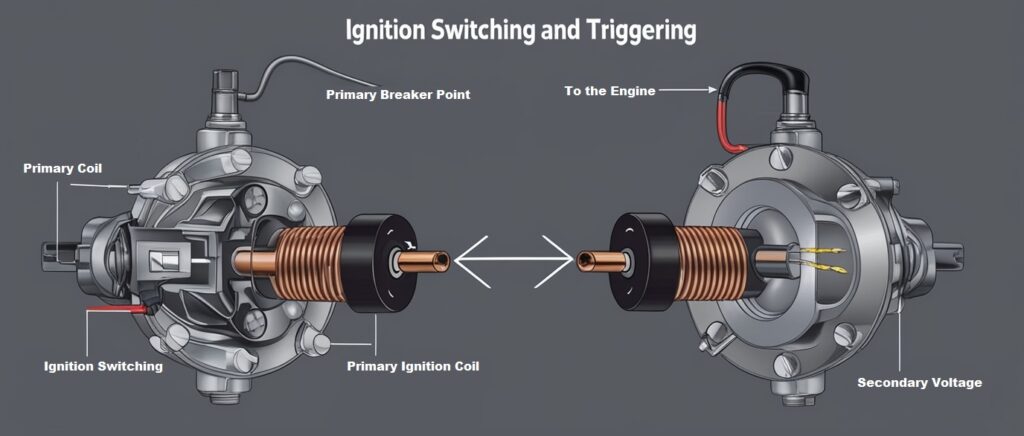

Conventional Ignition System

The conventional ignition system, in use since the early 1900s, is primarily mechanical. It operates with two electrical circuits—the primary and secondary circuits. The primary circuit carries low voltage from the battery and is controlled by breaker points and the ignition switch. When the ignition key is turned on, a low voltage current flows through the primary windings of the ignition coil, creating a magnetic field. As the engine rotates, the distributor shaft mechanically interrupts the current flow, causing a surge of high voltage in the secondary coil that is sent to the spark plugs.

Advantages and Disadvantages

Pros of this system include ease of maintenance due to its mechanical nature. However, it is considered the most unreliable ignition system, often requiring adjustments or component replacements every 12,000 miles. Deterioration over time can lead to engine misfires and other issues.

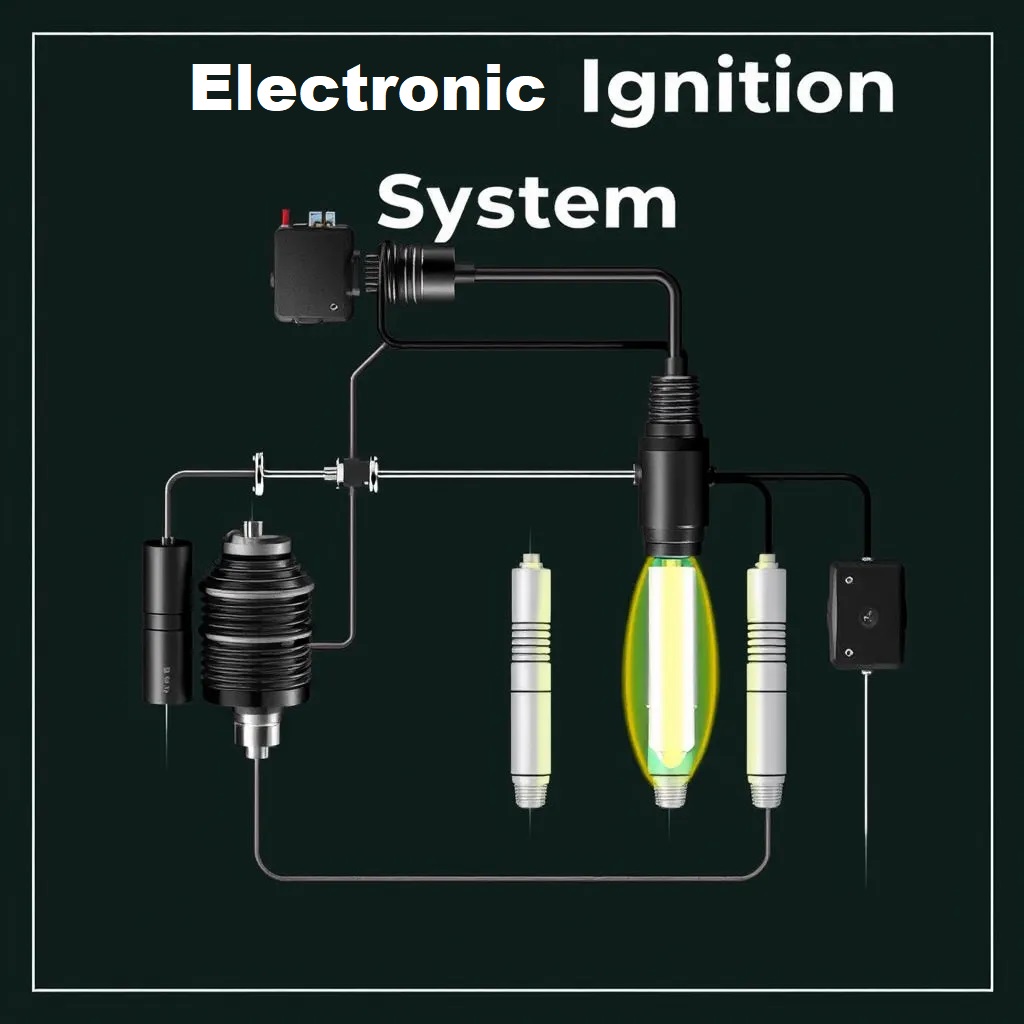

Electronic Ignition System

Emerging in the early 1970s, electronic ignition systems marked a significant advancement in ignition technology. These systems utilize solid-state components to replace mechanical breaker points, which enhances reliability and reduces maintenance requirements. Some versions extend the life of the ignition system by using transistors, allowing a small current in the input circuit to control a much larger current in the output circuit, resulting in more efficient ignition timing and operation.

Distributor-less Ignition System

The distributor-less ignition system (DIS) is the most recent evolution in ignition technology, introduced in the mid-1980s. In this system, coils are mounted directly on top of the spark plugs, eliminating the need for spark plug wires and allowing for completely electronic control by the vehicle’s onboard computer.

This setup is often referred to as a “direct ignition” system. One of the significant advantages of DIS is its minimal maintenance requirement, with many manufacturers specifying up to 100,000 miles between services. Drivers with DIS typically enjoy better fuel efficiency and reduced operational issues compared to older systems.

Benefits of Evolution

The evolution of ignition systems has brought multiple benefits to automotive technology. Newer ignition systems not only provide better fuel efficiency and reliable operation but also contribute to lower maintenance costs. Although they may require more expensive maintenance procedures, the long intervals between services mean that many drivers may never need to incur these costs.

Ignition Triggering Mechanisms

Ignition triggering mechanisms are critical components in the ignition systems of internal combustion engines, enabling the precise timing necessary for optimal engine performance. The triggering mechanism is responsible for initiating the spark that ignites the fuel-air mixture at the appropriate moment during the engine’s combustion cycle.

Basic Functionality

The ignition system operates on the principle of electromagnetic induction, which is essential for generating the spark needed to ignite the fuel-air mixture in the combustion chamber. When the ignition switch is activated, a low-voltage electrical current from the battery flows into the primary winding of the ignition coil. This action generates a magnetic field around the coil.

Once the ignition control module or distributor determines the right moment for spark generation, it interrupts the current flow in the primary winding. This sudden interruption causes the magnetic field to collapse, inducing a high-voltage current in the secondary winding of the ignition coil, which then travels to the spark plugs to create a spark that ignites the air-fuel mixture.

Timing and Control

The timing of the ignition spark is vital for efficient engine operation. Ignition timing can be static or dynamic. Static ignition timing is a manufacturer-set parameter, optimized for average operating conditions and does not adapt to changes in engine load or speed. In contrast, dynamic ignition timing adjusts based on real-time engine parameters, such as load and speed, allowing the engine control unit (ECU) to optimize performance and efficiency. This adjustment is critical for maximizing power output, improving fuel efficiency, and reducing harmful emissions by ensuring complete combustion of the air-fuel mixture.

Types of Ignition Systems

There are several types of ignition systems that utilize different triggering mechanisms:

Spark Ignition Systems

Used primarily in petrol engines, spark ignition systems create a spark to ignite the air-fuel mixture just before each combustion stroke. These systems have evolved from early magneto and trembler coil systems to modern electronic ignition systems, which became prevalent in the late 20th century.

Compression Ignition Systems

In diesel engines, ignition is achieved through compression rather than an ignition spark. The heat generated from compressing the air-fuel mixture ignites it, eliminating the need for a traditional ignition system. Diesel engines may utilize glow plugs to preheat the combustion chamber, facilitating starting in cold conditions.

Electronic Ignition Systems

Modern vehicles often employ electronic ignition systems that use sensors to monitor various engine parameters and adjust ignition timing accordingly. This enables improved fuel economy, reduced emissions, and enhanced overall engine performance.

Applications

Automotive Industry

Ignition switching and triggering systems play a critical role in the automotive industry, particularly with the increasing shift towards electric vehicles (EVs). The rising demand for EVs, driven by environmental concerns and government incentives, is fostering the development of innovative ignition system technologies tailored specifically for electric drivetrains. High-voltage ignition systems are gaining traction as they effectively manage the high-voltage requirements essential for reliable performance in electric vehicles.

Ignition Interlock Devices

Another significant application is in the realm of ignition interlock devices (IIDs), which are installed in vehicles to prevent impaired driving. These devices require users to submit a breath sample to assess their Blood Alcohol Content (BrAC) before allowing the engine to start. The user-friendly design of modern IIDs, such as those from Intoxalock, simplifies the process by utilizing a one-button operating system, enhancing compliance and ease of use. Collaborative efforts among automotive manufacturers, insurance companies, and tech firms are promoting IID integration, thereby decreasing drunk driving incidents through broader adoption and streamlined installation processes.

Technological Advancements

The automotive sector is experiencing continuous technical advancements, with innovations such as electronic ignition systems and distributor-less ignition systems enhancing overall vehicle performance. Manufacturers are adapting to these advancements to meet the demands of new vehicle types, including passenger, light commercial, and off-road vehicles. The advent of connected technologies, such as smartphone integration for real-time monitoring, is also influencing the design and functionality of ignition systems, particularly in IIDs.

Future Trends

The Ignition Interlock Device (IID) market is poised for significant transformation driven by technological advancements and evolving regulatory landscapes. As the market integrates advanced analytics, machine learning, and real-time data collection, stakeholders are gaining enhanced insights into consumer behaviors and regulatory impacts, which are crucial for shaping future market trends.

Technological Advancements

One of the most notable trends is the increasing adoption of sophisticated technologies that enable better monitoring and analysis of IID performance. These innovations not only improve the efficiency of device operation but also enhance user experience, thus driving greater acceptance among consumers. The implementation of data-driven strategies is expected to support the development of more reliable and user-friendly devices, potentially increasing market penetration.

Market Growth

The IID market is projected to grow at a compound annual growth rate (CAGR) of 14.7% from 2024 to 2031. This growth underscores the increasing emphasis on road safety and compliance with emerging regulations. As governments worldwide continue to enforce stricter measures to curb impaired driving, the demand for IIDs is anticipated to rise sharply, propelling industry players to innovate and adapt accordingly.

Regulatory Changes

With the introduction of new legislation in various regions, manufacturers are being compelled to modify their product offerings. Regulatory bodies are focusing on enhancing safety measures, which will likely create opportunities for companies that can swiftly adapt their technologies to meet these standards. In regions such as California and New York, where stringent zero-emission mandates are being implemented, the IID market will have to align with these regulatory frameworks while remaining viable and accessible to consumers.

Customer-Centric Strategies

Market strategies are increasingly prioritizing customer-centric approaches. Companies are focusing on understanding consumer preferences and adapting their products accordingly, which is critical for fostering loyalty and enhancing user satisfaction. This trend emphasizes the need for ongoing engagement with users to gather feedback and insights that can drive future developments in IID technology.

Safety Considerations

Alcohol-Related Crashes

Driving under the influence of alcohol significantly increases the risk of motor vehicle crashes, leading to numerous fatalities and injuries each year. To combat this pressing public safety issue, various states have implemented ignition interlock programs. These programs mandate the installation of ignition interlock devices in vehicles operated by individuals convicted of driving under the influence (DUI). These devices function by requiring the driver to blow into a breathalyzer before starting the vehicle; if alcohol is detected above a predetermined limit, the vehicle will not start, thereby preventing impaired driving incidents.

Effectiveness of Ignition Interlocks

Research indicates that ignition interlock devices are effective in reducing alcohol-impaired driving and alcohol-related crashes. Systematic reviews have shown that states with strong ignition interlock laws experience fewer fatal motor vehicle crashes related to alcohol compared to states without such laws. The National Highway Traffic Safety Administration (NHTSA) provides critical support to states in implementing these programs, emphasizing the need for evidence-based strategies to enhance their effectiveness.

Operator Safety in Vehicle Operation

In addition to DUI prevention, general operator safety is paramount in vehicle operation. The use of safety features, such as interlocks and redundancies, can significantly mitigate risks associated with operator error. For instance, machinery equipped with dual-button controls for activation can help prevent accidental operations that may endanger the operator. This principle applies similarly to vehicle safety systems aimed at preventing alcohol-related crashes, where user compliance with safety mechanisms is essential for optimal function.

Redundancy and Reliability

The reliability of ignition systems, especially electronic ignition systems, plays a crucial role in overall vehicle safety. Traditional systems often suffer from wear and tear, leading to issues such as misfires, which can compromise safety and increase harmful emissions. In contrast, electronic ignition systems offer improved reliability through precise timing and reduced maintenance needs, which not only prolongs engine life but also enhances the safety of vehicle operation. Therefore, integrating advanced ignition technologies can further bolster vehicle safety in conjunction with DUI prevention strategies.