Interview Questions On Fluid Mechanics

If you are looking for a high-paying job in the mechanical engineering field, then you able to answer the right interview questions on fluid mechanics. Fluid mechanics is one of the most demanding career fields in this industry. You need to have great knowledge about fluids and how they behave under various conditions.

Fluid mechanics is the branch of physics concerned with the behavior of fluids. Fluid mechanics provides insight into many phenomena observed in everyday life, such as weather patterns, ocean currents, waves, and even drinking straws.

Fluid dynamics, which is a subset of fluid mechanics, studies the flow of fluids and the forces on them. Fluid dynamics has multiple applications such as to vehicle design (e.g. wings, fins), airplane design (e.g., wing shape) and NACA ducts in cars. Fluid dynamics also plays a very important role in various other areas such as acoustics, oceanography etc.

What makes fluid mechanics so important to our daily lives? What are some common applications of fluid mechanics? To answer this question, we’ll explore how fluid mechanics is related to several common phenomena.

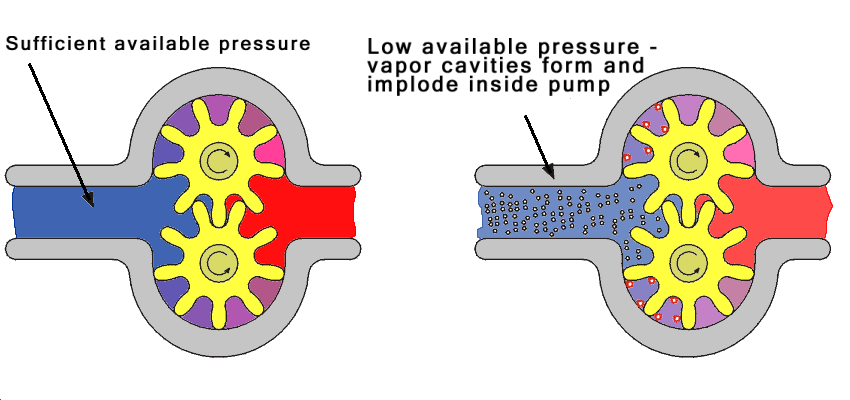

1. How Cavitation can be eliminated in a Pump?

Cavitation means bubbles are forming in the liquid.

· To avoid Cavitation, we have to increase the Pump size to One or Two Inch;

· To increase the pressure of the Suction Head, or

· Decrease the Pump Speed.

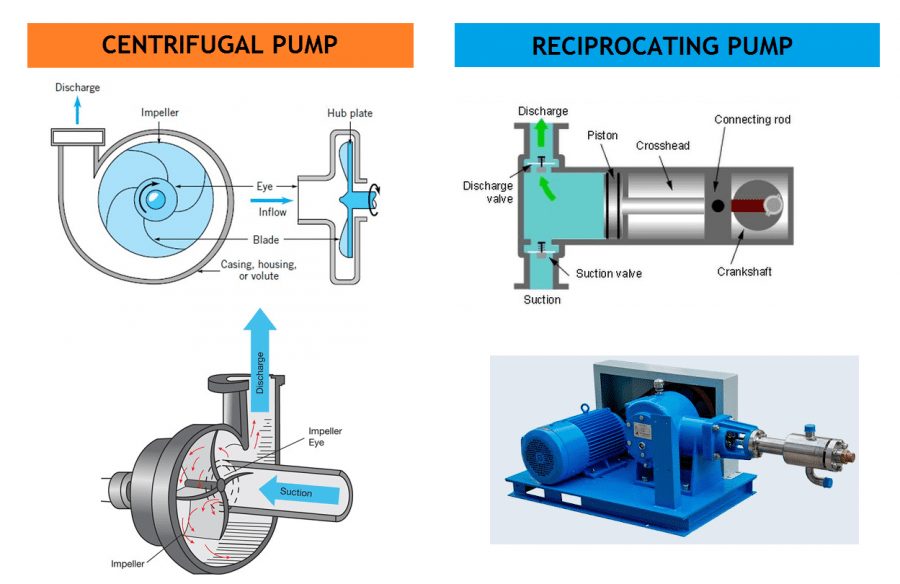

2. Which pump is more efficient Centrifugal pump or Reciprocating pump?

Centrifugal pump.

Because flow rate is higher compared to reciprocating pump. Flow is smooth and it requires less space to install. Lower initial cost and lower maintenance cost.

3. Why Centrifugal Pump is not called as a Positive Displacement Type of Pump?

The centrifugal has varying flow depending on pressure or head, whereas the Positive Displacement pump has more or less constant flow regardless of pressure.

Likewise viscosity is constant for positive displacement pump where centrifugal pump have up and down value because the higher viscosity liquids fill the clearances of the pump causing a higher volumetric efficiency. When there is a viscosity change in supply there is also greater loss in the system. This means change in pump flow affected by the pressure change.

One more example is, positive displacement pump has more or less constant efficiency, where centrifugal pump has varying efficiency rate.

4. Why the centrifugal pump is called high discharge pump?

Centrifugal pump is a kinetic device. The centrifugal pump uses the centrifugal force to push out the fluid. So the liquid entering the pump receives kinetic energy from the rotating impeller. The centrifugal action of the impeller accelerates the liquid to a high velocity, transferring mechanical (rotational) energy to the liquid. So it discharges the liquid in high rate. It is given in the following formulae:

Centrifugal force F= (M*V2)/R.

Where,

M-Mass

V-Velocity

R-Radius

5. Why cavitation will occur in Centrifugal Pumps and not in Displacement pumps?

The formation of cavities (or bubbles) is induced by flow separation, or non-uniform flow velocities, inside a pump casing. In centrifugal pumps the eye of the pump impeller is smaller than the flow area of pipe. This decrease in flow area of pump results in increase in flow rate. So pressure drop happened between pump suction and the vanes of the impeller. Here air bubbles or cavities are formed because of liquid vapour due to increase in temperature in impeller. This air bubbles are transmitted to pump which forms cavitation.

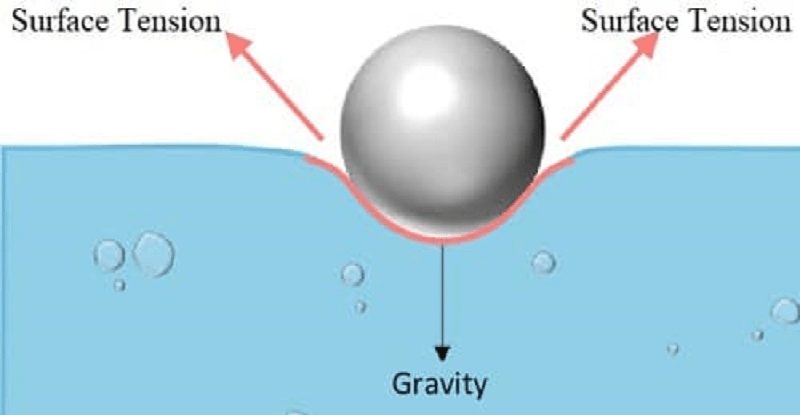

6. Surface tension is due to

- Viscous forces

- Cohesion

- Adhesion

- The difference between adhesive and cohesive forces

Answer:

Cohesion

Explanation:

Surface tension is due to cohesion between liquid particles at the surface, where as capillarity is due to both cohesion and adhesion. The property of cohesion enables a liquid to resist tensile stress, while adhesion enables it to stick to another body.

7. Which property of mercury is the main reason for use in barometers?

- High density

- Negligible capillary effect

- Very low vapour pressure

- Low compressibility

Answer:

Very Low Vapour Pressure

8. When can a piezometer be not used for pressure measurement in pipes?

- The pressure difference is low

- The velocity is high

- The fluid in the pipe is a gas

- The fluid in the pipe is highly viscous

Answer:

The fluid in the pipe is a gas

9. The reading of the pressure gauges fitted on a vessel is 25 bar. The atmospheric pressure is 1.03 bar and the value of g is 9.81 m/s2. The absolute pressure in the vessel is

- 23.97 bar

- 25.00 bar

- 26.03 bar

- 34.84 bar

Answer:

26.03 bar

Explanation:

Absolute pressure = Atmospheric pressure + Gauge pressure

= 25 + 1.03 = 26.03 bar

10. Resultant pressure of the liquid in case of an immersed body acts through which one of the following?

- Centre of gravity

- Centre of pressure

- Metacentre

- Centre of buoyancy

Answer:

Centre of pressure

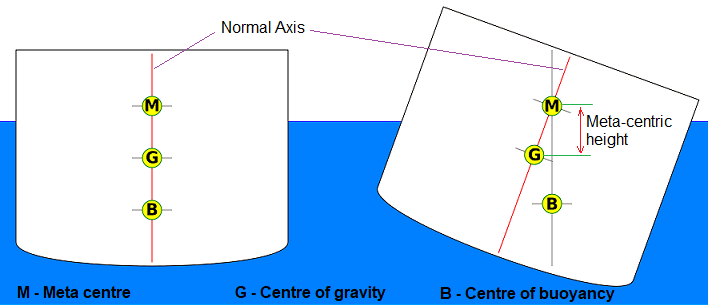

11. Bodies in floatation to be in stable equilibrium, the necessary and sufficient condition is that the centre of gravity is located below the

- Metacentre

- Centre of pressure

- Centre of gravity

- Centre of buoyancy

Answer:

Metacentre

12. What is buoyant force?

- Lateral surface acting on a submerged body

- Resultant force acting on a submerged body

- Resultant hydrostatic force on a body due to fluid surrounding it

- None of the above

Answer:

Resultant hydrostatic force on a body due to fluid surrounding it.

Explanation:

When a body is either wholly or partially immersed in a fluid, a lift is generated due to the net vertical component of hydrostatic pressure forces experienced by the body. This lift is called the buoyant force and the phenomenon is called buoyancy.

13. For floating bodies, how is the metacentric radius defined?

- The distance between centre of gravity and the metacentre

- Second moment of area of plane of flotation about centroidal axis perpendicular to plane of rotation / immersed volume

- The distance between centre of gravity and the centre of buoyancy

- Moment of inertia of the body about its axis of rotation / immersed volume

Answer:

The distance between centre of gravity and the metacentre

Explanation:

Metacentric radius or Metacentric height is the distance between centre of gravity and the metacentre

14. The metacentric height of a passenger ship is kept lower than that of a naval or a cargo ship because

- Apparent weight will increase

- Otherwise it will be in neutral equilibrium

- It will decrease the frequency of rolling

- Otherwise it will sink and be totally immersed

Answer:

It will decrease the frequency of rolling

15. A bucket of water hangs with a spring balance. If an iron piece is suspended into water from another support without touching the sides of the bucket, the spring balance will show

- An increased reading

- A decreased reading

- No change in reading

- Increased or decreased reading depending on the depth of immersion

Answer:

No change in reading

16. What are the forces that influence the problem of fluid static?

- Gravity and viscous forces

- Gravity and pressure forces

- Viscous and surface tension forces

- Gravity and surface tension forces

Answer:

Gravity and pressure forces influence the problem of fluid statics

17. The Euler’s equation of motion is a statement of

- Energy balance

- Conservation of momentum for an inviscid fluid

- Conservation of momentum for an incompressible flow

- Conservation of momentum for real fluid

Answer:

Conservation of momentum for an inviscid fluid

18. A tank containing water has two orifices of the same size at depths of 40 cm and 90 cm below the free surface of water. The ratio of discharge through these orifices is

- 1:1

- 2:3

- 4:9

- 16:81

Answer:

2:3

Explanation:

The ratio of discharges will be proportional to jet velocities, and will be proportional to their square root of water heads at the same size orifices. As a result, Q1 / Q2 = A1V1 / A2V2 ∝ √h1/h2

Q1/Q2 = √40/90 = 2/3.

19. What is the difference between Newtonian and non-Newtonian fluids?

Newtonian fluids are characterized by a linear relationship between shear stress and shear rate. In other words, their viscosity remains constant regardless of the applied force. Examples include water, air, and most gases.

Non-Newtonian fluids, on the other hand, exhibit a non-linear relationship between shear stress and shear rate. Their viscosity changes depending on the applied force or the duration of the force. Examples include:

- Shear-thinning fluids (e.g., ketchup, paint)

- Shear-thickening fluids (e.g., cornstarch in water)

- Bingham plastics (e.g., toothpaste)

Understanding the distinction between these fluid types is crucial in many engineering applications, from designing pumps and pipelines to formulating consumer products.

20. Explain the concept of Reynolds number and its significance in fluid mechanics.

The Reynolds number (Re) is a dimensionless quantity that helps predict flow patterns in different fluid flow situations. It is defined as:

Re = (ρVL) / μ

Where:

- ρ is the fluid density

- V is the fluid velocity

- L is the characteristic length

- μ is the dynamic viscosity of the fluid

The Reynolds number is significant because it indicates whether a flow will be laminar or turbulent:

- Low Reynolds numbers (Re < 2300) typically indicate laminar flow

- High Reynolds numbers (Re > 4000) generally suggest turbulent flow

- The range between 2300 and 4000 is considered transitional

Engineers use the Reynolds number to:

- Design efficient piping systems

- Optimize aerodynamic and hydrodynamic shapes

- Scale fluid flow experiments

- Predict heat transfer and mass transfer rates in various systems

21. What is Bernoulli’s principle, and how is it applied in real-world situations?

Bernoulli’s principle states that in a steady flow, an increase in the speed of a fluid occurs simultaneously with a decrease in pressure or a decrease in the fluid’s potential energy. Mathematically, it is expressed as:

P + (1/2)ρv² + ρgh = constant

Where:

- P is pressure

- ρ is fluid density

- v is fluid velocity

- g is gravitational acceleration

- h is height

This principle has numerous practical applications, including:

- Airfoil Design: The shape of an airplane wing creates a pressure difference that generates lift.

- Venturi Effect: Used in carburetors, spray bottles, and flow measurement devices.

- Pitot Tubes: Measure airspeed in aircraft.

- Hydraulic Systems: Utilized in various industrial and automotive applications.

- Blood Flow: Helps explain the relationship between blood pressure and vessel diameter in the circulatory system.

Understanding Bernoulli’s principle is crucial for engineers working on fluid systems, from designing efficient pumps to optimizing wind turbine blades.

22. Describe the concept of boundary layer and its importance in fluid mechanics.

The boundary layer is a thin region of fluid near a solid surface where viscous forces are significant. This concept, introduced by Ludwig Prandtl in 1904, revolutionized our understanding of fluid dynamics.

Key characteristics of the boundary layer include:

- Velocity Gradient: The fluid velocity changes from zero at the surface (no-slip condition) to the free-stream velocity at the edge of the boundary layer.

- Thickness: The boundary layer thickness grows along the surface in the direction of flow.

- Laminar vs. Turbulent: The boundary layer can be laminar or turbulent, depending on the Reynolds number and surface conditions.

The boundary layer concept is crucial in:

- Drag Reduction: Understanding boundary layers helps in designing more aerodynamic vehicles and reducing energy consumption.

- Heat Transfer: Thermal boundary layers affect heat exchange between fluids and solids.

- Separation: Boundary layer separation can lead to increased drag and reduced lift in aerodynamics.

- Mixing and Diffusion: Boundary layers influence mass transfer processes in chemical engineering applications.

Engineers must consider boundary layer effects when designing anything from airplane wings to heat exchangers and chemical reactors.

23. What is cavitation, and why is it a concern in fluid systems?

Cavitation is a phenomenon that occurs when the local pressure in a liquid drops below its vapor pressure, causing the formation of vapor bubbles. When these bubbles collapse, they can cause significant damage to surrounding surfaces.

Key points about cavitation:

- Causes: Rapid changes in fluid velocity or pressure, often in pumps, propellers, or valves.

- Effects:

- Material erosion and pitting

- Noise and vibration

- Reduced efficiency in pumps and turbines

- Potential for catastrophic failure in extreme cases

- Prevention and Mitigation:

- Proper system design to maintain adequate pressure

- Use of materials resistant to cavitation damage

- Careful control of fluid velocity and pressure gradients

- Implementation of anti-cavitation devices or coatings

Understanding and preventing cavitation is crucial in various industries, including:

- Marine engineering (ship propellers)

- Hydroelectric power generation

- Chemical processing plants

- Water treatment facilities

Engineers must consider cavitation potential when designing any system involving high-speed liquid flow or rapid pressure changes.

Key Concepts in Fluid Mechanics

- Fluid Properties: Understanding the characteristics of fluids, such as density, viscosity, and compressibility.

- Fluid Statics: The study of fluids at rest, including concepts like pressure and buoyancy.

- Fluid Dynamics: The analysis of fluids in motion, covering topics like flow rates, turbulence, and drag.

- Conservation Laws: Applying the principles of conservation of mass, momentum, and energy to fluid systems.

Advanced Topics in Fluid Mechanics

To truly stand out in an interview, it’s beneficial to demonstrate knowledge of more advanced concepts in fluid mechanics. Here are some topics that could set you apart:

1. Computational Fluid Dynamics (CFD)

CFD is a branch of fluid mechanics that uses numerical analysis and data structures to analyze and solve problems involving fluid flows. It’s widely used in:

- Aerospace engineering for aircraft and spacecraft design

- Automotive industry for vehicle aerodynamics

- Weather forecasting and climate modeling

- Biomedical engineering for studying blood flow

Familiarity with CFD software like ANSYS Fluent or OpenFOAM can be a significant advantage in many engineering roles.

2. Multiphase Flows

Multiphase flows involve the simultaneous flow of materials with different states or phases. This complex field is crucial in:

- Oil and gas industry (e.g., pipeline transport)

- Chemical reactors and process equipment

- Environmental engineering (e.g., sediment transport in rivers)

- Nuclear reactor cooling systems

Understanding the challenges and modeling techniques for multiphase flows can demonstrate a deep knowledge of fluid mechanics.

3. Non-Newtonian Fluid Dynamics

While we touched on non-Newtonian fluids earlier, a deeper understanding of their behavior is valuable in many industries:

- Food processing (e.g., designing mixing and pumping systems)

- Polymer processing

- Biomedical applications (e.g., blood flow modeling)

- Drilling fluids in the oil and gas industry

Knowledge of constitutive models for non-Newtonian fluids and their applications can be impressive in an interview setting.

Practical Applications and Case Studies

To truly demonstrate your expertise in fluid mechanics, it’s valuable to discuss real-world applications and case studies. Here are a few examples:

- Microfluidics in Medical Diagnostics: Explain how fluid mechanics principles are applied in designing lab-on-a-chip devices for rapid, point-of-care medical testing.

- Wind Turbine Blade Design: Discuss how computational fluid dynamics is used to optimize wind turbine blade shapes for maximum efficiency.

- Natural Gas Pipeline Network Optimization: Describe how fluid mechanics principles are applied to design and manage complex pipeline networks for efficient gas distribution.

- Aircraft Wing Design: Explain the role of fluid mechanics in developing advanced wing designs, such as winglets, to reduce drag and improve fuel efficiency.

- Hydraulic Fracturing in Oil and Gas Extraction: Discuss how understanding fluid mechanics is crucial for optimizing fracking operations and predicting fluid behavior in porous media.

By relating fluid mechanics principles to these practical applications, you demonstrate not only theoretical knowledge but also an understanding of how these concepts are applied in industry.

Conclusion

Mastering fluid mechanics is essential for success in many engineering fields. By thoroughly understanding the fundamental concepts, being able to solve complex problems, and staying aware of cutting-edge applications, you’ll be well-prepared for any fluid mechanics interview or professional challenge.

Remember, fluid mechanics is a vast and evolving field. Continuous learning and staying updated with the latest research and industry trends will help you maintain and expand your expertise throughout your career.