Introduction

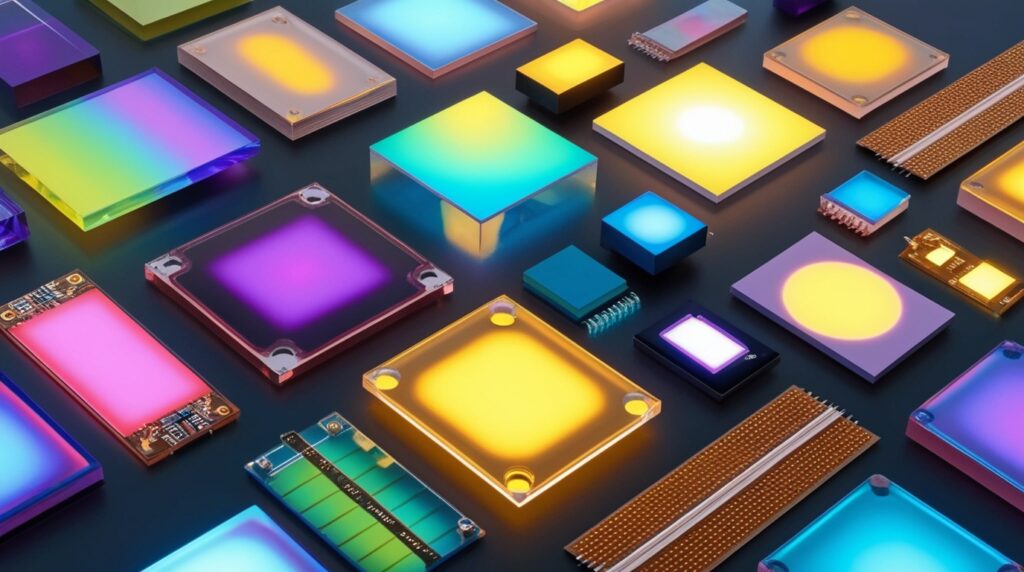

Perovskite light-emitting diodes (PeLEDs) represent a groundbreaking advancement in optoelectronics, leveraging the unique properties of perovskite materials to produce highly efficient light-emitting devices. Emerging in the early 2010s, PeLEDs have gained attention due to their remarkable luminescence and tunable emission spectra, leading to their potential application in next-generation displays, lighting, and flexible electronics. Their significance is underscored by a rapid increase in research and development, which positions PeLEDs as a promising alternative to traditional light-emitting technologies like organic LEDs (OLEDs) and inorganic semiconductors.

The notable advantages of PeLEDs include their high photoluminescence quantum yields (PLQY), ease of fabrication through solution-based processes, and the capability to produce vibrant colors across a wide range of wavelengths. However, the commercialization of PeLEDs is not without challenges. Significant issues, such as operational stability, longevity, and the toxicity of some precursor materials, have sparked ongoing debates within the scientific community regarding their practical applications and environmental impact. These concerns are particularly pertinent as researchers explore alternative, less toxic materials for the development of PeLEDs.

Despite these challenges, the ongoing pursuit of enhanced stability and performance has led to substantial innovations in device architecture and material engineering. Recent breakthroughs indicate that with continued research, PeLEDs could transform the landscape of optoelectronics, possibly heralding a new era characterized by flexible and efficient lighting solutions. The field is now poised for significant advancements, as projections suggest a rapid escalation in the adoption of PeLED technology over the coming decade, potentially marking it as the “decade of perovskite optoelectronics.”

The evolving narrative of PeLEDs reflects a broader trend towards sustainable and efficient lighting technologies, balancing the promise of advanced materials with pressing concerns over environmental sustainability and health impacts. As the field progresses, addressing these controversies and fostering responsible development will be essential for ensuring the long-term viability of perovskite-based devices in commercial applications.

History

The development of perovskite light-emitting diodes (PeLEDs) is relatively recent, building on the groundwork laid by earlier research into perovskite materials for photovoltaic applications. The initial interest in perovskites as optoelectronic materials was sparked by their unique photophysical properties, which demonstrated promise in solar cells since the first successful demonstration in 2009 by Kojima et al. In the following years, researchers began exploring the potential of perovskites in light-emitting applications, leading to significant advancements in device efficiency and performance.

By around 2014, PeLEDs had started to emerge as a new category of light-emitting devices, leveraging the inherent advantages of perovskite materials, such as high luminescence and tunable emission wavelengths. Despite the initial excitement, the commercialization of PeLEDs has faced significant hurdles, primarily due to challenges associated with operational stability and efficiency. The pursuit of improved performance and longevity in PeLEDs has driven extensive research, focusing on strategies such as optimizing material properties and integrating advanced photonic structures to enhance light outcoupling.

As of recent developments, the field has garnered substantial attention, with predictions suggesting that the next decade may see a rapid escalation in the adoption of PeLED technology, potentially marking the onset of what could be called the “decade of perovskite optoelectronics.

Structure

Overview of Perovskite Materials

Perovskites are a significant class of crystalline compounds characterized by the general formula ABX3, where A and B are cations, and X represents an anion, typically a halide or oxide. The B-site cation forms octahedral structures with anions, while the A-site cations are coordinated in a 12-fold manner. This three-dimensional network can be modified to create lower-dimensional frameworks, such as layered two-dimensional (2D) perovskites, by incorporating larger organic cations at the A-site, leading to a rich variety of optoelectronic properties.

Three-Dimensional Bulk Perovskites

The three-dimensional bulk perovskite structure, particularly lead halide perovskites, demonstrates a strong influence on optoelectronic properties. The valence band comprises the s2 lone pair of Pb2+ and halide p-orbitals, while the conduction band is formed by lead 6p and halide p-orbitals. The connectivity and geometry of the metal-halide framework can be adjusted through the choice of A-site cations, leading to octahedral tilting that affects the electronic structure near the band edges. These materials exhibit low formation energies, allowing for facile growth and processing from lower purity starting materials, along with a high tolerance to defects compared to conventional semiconductors such as GaAs.

Two-Dimensional Perovskites

Two-dimensional (2D) perovskites have emerged as promising candidates in optoelectronics, leveraging their structural versatility and unique properties. By utilizing large organic A-site cations, researchers have developed layered structures that incorporate interlayers of organic material. These 2D perovskites exhibit significantly higher exciton binding energies (hundreds of millielectronvolts) compared to their 3D counterparts, along with impressive photoluminescence quantum yields (PLQY) of approximately 88% for certain blue light-emitting diodes (LEDs). The general formula for these structures is L2An−1PbnX3n−1, indicating a configuration where [PbX6]4− octahedral units are separated by organic chain barrier layers.

Implications for Light-Emitting Diodes

The structural characteristics of perovskites play a crucial role in the performance of perovskite light-emitting diodes (PeLEDs). The tunable bandgap resulting from compositional engineering allows for efficient emission across a range of wavelengths, making perovskites particularly advantageous for LED applications. Additionally, the use of solution-based processes facilitates the fabrication of thin films and devices, contributing to their rising popularity in electronic systems. Despite their promising optoelectronic properties, challenges related to durability and operational efficiency remain, necessitating ongoing research and development to enhance their practicality for commercial applications.

Working Principle

Perovskite light-emitting diodes (PeLEDs) operate based on the unique properties of perovskite materials, which exhibit high photoluminescence quantum yields (PLQY) and tunable emission characteristics. The foundational mechanism involves the excitation of charge carriers (electrons and holes) within the perovskite layer, followed by their recombination to produce light.

Charge Carrier Dynamics

The interaction of charge carriers with the crystal lattice is crucial for determining the efficiency of light emission. As charge carriers move through the material, they can induce localized lattice deformations, which help to spatially localize these carriers, thereby preventing non-radiative recombination. Munson et al. demonstrated that large polarons, formed at elevated temperatures, increase electron–phonon coupling, which correlates with longer charge recombination lifetimes in perovskite films. This prolonged recombination time enhances light emission efficiency, allowing for high performance in PeLEDs.

Energy Funneling

An essential aspect of PeLEDs is the energy funneling process, where charge carriers injected into larger bandgap domains are quickly transferred to energetically favorable lower bandgap regions. This transfer occurs so rapidly that it outpaces non-radiative recombination processes, effectively concentrating charge carriers in the emitting domains. This mechanism not only minimizes non-radiative losses but also shifts the recombination dynamics to a bimolecular regime, promoting higher localized charge densities necessary for effective light emission.

Device Configuration

The architecture of PeLEDs is vital for optimizing their performance. The integration of photonic structures with the device stack can enhance light outcoupling and prevent device degradation. Systematic studies are focusing on the careful selection and seamless integration of these photonic elements, which are critical for achieving desired efficiencies and stabilities in light emission.

Role of Dimensionality

Recent advancements in perovskite nanostructures have leveraged reduced dimensions, such as one-dimensional and zero-dimensional systems, which show promise for producing high-quality emission. These lower-dimensional materials benefit from improved exciton self-trapping, leading to efficient light emission while also demonstrating enhanced environmental stability. The geometrical reduction of emitters, such as through the fabrication of nanocrystals or quantum dots, provides a pathway for tunable, color-pure emissions, further augmenting the performance of PeLEDs.

Fabrication Methods

Perovskite light-emitting diodes (PeLEDs) can be produced using various fabrication methods, each with its unique advantages and limitations. The primary methods include vapor deposition technologies, solution-based techniques, and emerging printing methods.

Vapor Deposition Technologies

Vapor deposition methods, such as chemical vapor deposition (CVD) and physical vapor deposition (PVD), are often favored for their ability to produce high-quality perovskite thin films. These techniques generally allow for a reduction in intermediate processing steps, such as anti-solvent usage and annealing, which are commonly required in other methods. However, these techniques typically require a high vacuum atmosphere, classifying them as vacuum thermal evaporation (VTE) methods. VTE methods are increasingly adopted for industrial applications, particularly in the fabrication of OLED displays, and they promise a pathway to develop efficient PeLEDs.

The CVD process involves several elementary steps, including the sublimation of solid precursors, which are then evaporated or co-evaporated under high vacuum conditions. This method efficiently transports precursor vapors to a cooler substrate, facilitating the formation of perovskite thin films without the need for extensive post-treatment annealing. This is particularly beneficial as it allows for deposition on flexible and uneven substrates, although the requirement for expensive vacuum equipment can hinder scalability.

Solution-Based Techniques

Among the most common techniques for PeLED fabrication is spin coating, noted for its simplicity and cost-effectiveness. Spin coating allows for rapid evaporation of the solvent, which initiates the nucleation of perovskite crystals while offering control over the crystallization kinetics on the substrate. However, this method generates considerable waste of precursor ink and is not ideal for large-scale production due to potential non-uniform film thickness and morphology.

Another solution-based approach is spray coating, where atomized droplets are directed onto a target surface, forming a wet film. The crystallization of the material occurs as the solvent evaporates. Key parameters such as precursor concentration, droplet size, and substrate temperature significantly affect the final film properties, requiring careful control to achieve the desired thickness and uniformity.

Emerging Printing Methods

Emerging methods like inkjet printing, slot die coating, and blade-coating show promise for cost-effective large-scale fabrication of PeLEDs. While these methods can enhance material utilization and reduce waste compared to spin coating, challenges remain in achieving the desired homogeneity and film quality.

Challenges and Future Directions

Despite the advancements in fabrication techniques, PeLEDs face significant challenges, particularly regarding operational lifetime. Current PeLEDs struggle to match the longevity of conventional LEDs and OLEDs, with operational lifetimes measured in minutes to hours, contrasting starkly with the thousands of hours achieved by traditional counterparts. Continued research is focused on enhancing device stability and exploring novel fabrication methods that can balance quality, scalability, and cost-effectiveness, aiming for commercial viability in the future.

Performance Characteristics

Stability Challenges

The stability of perovskite light-emitting diodes (PeLEDs) is a critical factor that affects their performance and commercial viability. Current challenges stem from both passive (ambient storage) and active (device operation) environments, which can lead to significant degradation. Specifically, ion migration and operational stability can result in color changes over time when the device operates under a constant voltage, thereby impacting color stability and overall efficiency. The degradation mechanisms are influenced by various external stresses, including light illumination, heat, moisture, and oxygen exposure, which must be managed to improve the longevity of PeLEDs.

Device Configuration and Efficiency

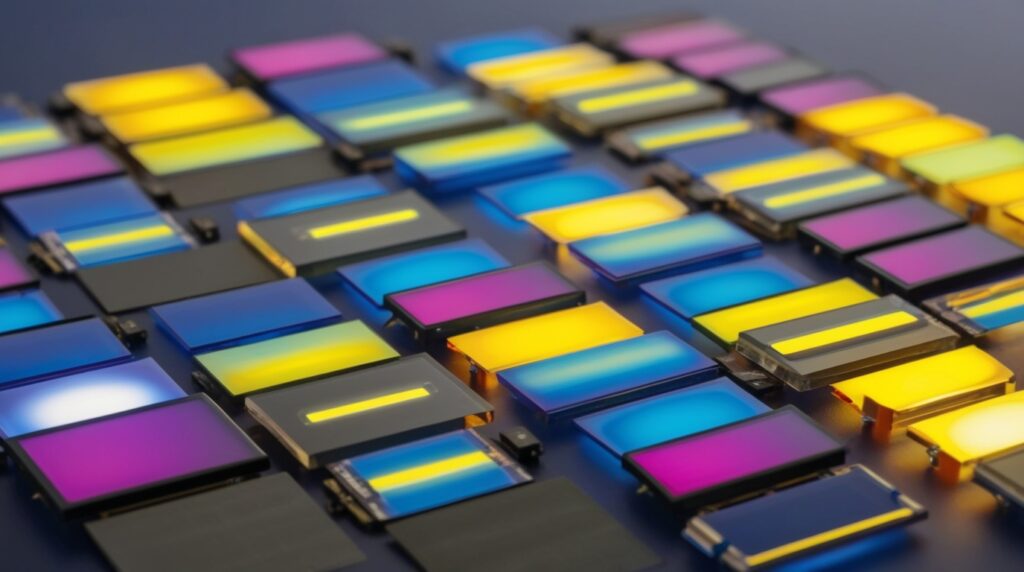

Achieving high efficiency in PeLEDs requires careful selection of materials and device architecture. The most promising configurations utilize indium tin oxide (ITO) as the transparent conducting oxide (TCO) electrode, along with materials like PEDOT:PSS as the hole transport material (HTM) and TPBi or ZnO as the electron transport material (ETM). These combinations have shown significant potential, yet the efficiency remains challenged by the intrinsic brittleness of ITO and its high production costs.

Color Purity and Emission Efficiency

The efficiency of PeLEDs is also tied to the color purity of emitted light. Innovations in nanostructured emitters, such as quantum dots and nanocrystals, have provided pathways to achieve tuneable and color-pure emissions. These materials demonstrate luminous efficiencies that can match or exceed traditional organic emitters, showcasing a promising avenue for enhancing PeLED performance.

Integration of Photonic Structures

Further improvement in efficiency can be obtained through the integration of photonic structures within the device stack. Enhancements in light outcoupling efficiency—achieved through precise control of nanostructures—have resulted in substantial increases in the internal quantum efficiency (IQE) of PeLEDs. Such innovations are essential not only for boosting performance but also for addressing the operational stability that currently lags behind that of commercial organic LEDs (OLEDs), with the longest reported lifetime of PeLEDs being in the hundreds of hours compared to thousands for OLEDs.

Applications

Display Technologies

Perovskite light-emitting diodes (PeLEDs) have emerged as a promising alternative to traditional display technologies due to their high brightness and color tunability. Reports indicate that PeLEDs can achieve sufficiently high luminance levels, making them suitable for various display applications, including ultrahigh-definition screens. Their unique properties, such as narrow emission linewidth and relatively low toxicity, position them favorably against commercial technologies like colloidal chalcogenide quantum dots and organic materials.

Nevertheless, the primary challenges of reproducibility and stability in perovskite films remain significant bottlenecks that researchers are actively addressing through improved deposition methods. Recent advancements have demonstrated the successful implementation of PeLEDs in digital displays, showcasing their potential in next-generation screens. Notably, a collaborative effort among researchers resulted in efficient and color-stable red-emitting PeLEDs, achieving peak external quantum efficiency of 28.7% at 638 nm, highlighting their commercial viability for various applications in lighting and displays.

Flexible Electronics

The rise of portable electronic devices and wearable technology has increased the demand for flexible power sources. PeLEDs offer a significant advantage in this area due to their compatibility with printing techniques on ultra-flexible substrates, enabling their integration into flexible power supply units. This compatibility makes them an attractive solution for powering devices in the Internet of Things (IoT), where reliable and lightweight energy sources are critical.

Photovoltaics

Perovskite solar cells (PSCs), closely related to PeLEDs, are also gaining attention for their application in space photovoltaics due to their ultrahigh power-to-weight ratio and low manufacturing costs. The operational stability of PSCs has been enhanced through research aimed at mitigating the effects of environmental stresses, allowing them to perform effectively even in challenging conditions, such as those found in space.

The potential for tandem solar cells, which combine PSCs with traditional silicon cells, offers a pathway for improving efficiency and market competitiveness. Studies have shown that perovskite-silicon tandem solar cells can achieve a power conversion efficiency of up to 33.9%, further underscoring the commercial prospects of perovskite technologies in the renewable energy sector.

Challenges and Limitations

Stability Issues

Beyond toxicity and environmental considerations, stability issues complicate the use of alternative materials. Tin-based solar cells, for instance, suffer from intrinsic instability due to spontaneous oxidation from Sn(II) to Sn(IV). This instability can hinder their performance and longevity, making them less reliable compared to traditional Pb-based options.

Environmental Impact of Alternatives

The exploration of alternatives to lead (Pb) in perovskite light-emitting diodes has raised significant concerns regarding their environmental impact. For instance, tin (Sn), often proposed as a less toxic substitute, exhibits a life cycle analysis (LCA) indicating that its environmental impact is 7 to 8 times higher than that of Pb. Furthermore, Sn’s price has surged, being currently ten times more expensive than Pb due to the concentrated production in countries like Peru, China, and Indonesia. The extraction and processing of Sn also contribute to global warming and terrestrial ecotoxicity, which are reported to be more than ten times greater than those associated with Pb.

Toxicity of Proposed Alternatives

Many alternative materials to Pb, such as indium (In) and bismuth (Bi), carry their own toxicity risks. Indium, extensively used in indium-doped tin oxide (ITO), has been linked to severe pulmonary damage and increased cancer rates among exposed workers. Chronic exposure to bismuth compounds may lead to serious health issues like encephalopathy and renal failure, although some studies suggest its low toxicity under certain conditions. The conflicting information regarding Bi’s safety necessitates further research to ascertain its viability as a Pb substitute in light-emitting diodes.

Scarcity and Economic Viability

The scarcity of some proposed alternatives also poses significant challenges. For example, germanium (Ge) and silver (Ag) are both expensive and not abundantly available. Ge, while exhibiting low toxicity, is rare in the Earth’s crust, making its extraction and processing economically unfeasible for large-scale applications. Similarly, Ag’s high cost and its environmental impact, particularly in the context of the photovoltaic industry, raise concerns about its future use in perovskite technologies.

Future Directions

Advancements in Lead-Trapping Materials

Future developments in perovskite light-emitting diodes (PeLEDs) should prioritize the innovation of advanced lead-trapping materials that offer multi-functional properties. These materials are expected to provide anti-reflection, self-cleaning capabilities, and defect passivation, all while demonstrating high robustness against environmental factors such as UV irradiation, heat, and moisture. Additionally, the materials must be cost-effective, reusable, and scalable for industrial applications to facilitate technology commercialization.

Integration with Flexible Power Supplies

As wearable electronics and portable devices gain prominence, flexible power supply units will become increasingly important for their integration with PeLEDs. The use of photovoltaic conversion technology as an external backup power source presents a promising avenue for enhancing the operational capabilities of these devices. Flexible perovskite solar cells (PSCs) can meet the demands of modern civilian portable equipment, although challenges remain regarding their chemical stability and the permeability of flexible polymer substrates to oxygen and moisture. Developing more stable encapsulation methods will be essential for achieving long-term reliability in these applications.

Enhancing Stability and Efficiency

Improving the bendability of all functional layers and enhancing interfacial adhesion in flexible perovskite solar cells (F-PSCs) are crucial for boosting both efficiency and stability. Notable advancements have been made, such as the introduction of iodine-terminated self-assembled monolayers at the electron transport layer/perovskite interface, which has successfully increased the power conversion efficiency (PCE) from 20.2% to 21.4% while also enhancing operational stability. Continued research should focus on optimizing these interfacial properties to further enhance the performance of PeLEDs.

Environmental and Economic Considerations

The sustainability of perovskite-based technologies is increasingly coming under scrutiny. As the photovoltaic (PV) industry expands, it will be necessary to address concerns regarding the environmental impact and economic viability of lead and other materials used in the production of PeLEDs. With projections suggesting a significant increase in silver demand for photovoltaics, alternatives must be explored to reduce reliance on scarce materials while maintaining device efficiency. The focus should be on ensuring that the production of PeLEDs remains environmentally safe and economically feasible, meeting both current and future energy needs.