Spark plugs are essential components in internal combustion engines, playing a crucial role in the ignition process. This comprehensive guide will explore the intricacies of spark plugs, their function, types, maintenance, and impact on engine performance. Whether you’re a car enthusiast or simply looking to understand your vehicle better, this article will provide valuable insights into these small but mighty engine parts.

What is a Spark Plug?

A spark plug is a device designed to fit into the cylinder head of an internal combustion engine. Its primary function is to deliver an electric current from the ignition system to the combustion chamber, igniting the compressed fuel-air mixture with a spark. This controlled explosion drives the engine’s pistons, converting chemical energy into mechanical power.

The Anatomy of a Spark Plug

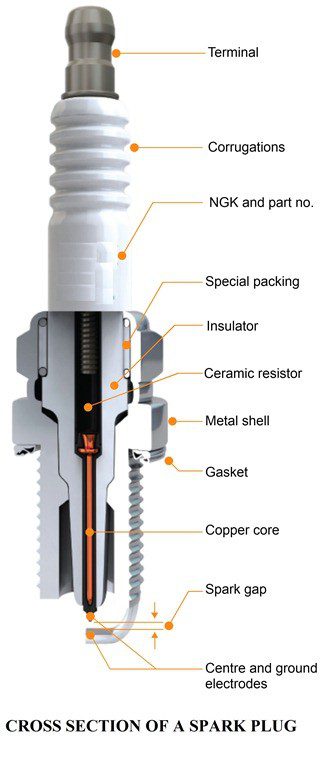

Understanding the structure of a spark plug is crucial to appreciating its function. Let’s break down its key components:

a) Terminal:

The top part of the spark plug that connects to the ignition system.

b) Insulator:

A ceramic material that surrounds the central electrode, providing electrical insulation.

c) Shell:

The metal casing that houses the internal components and threads into the engine.

d) Central Electrode:

The metal conductor that carries the high-voltage current.

e) Ground Electrode:

The bent metal piece attached to the shell, creating the spark gap.

f) Spark Gap:

The space between the central and ground electrodes where the spark occurs.

How Spark Plugs Work

The operation of a spark plug is a precise and rapid process:

- The ignition system generates a high-voltage electric current.

- This current travels through the spark plug’s terminal and down the central electrode.

- When the voltage overcomes the resistance of the spark gap, it arcs across to the ground electrode.

- This arc ignites the compressed fuel-air mixture in the combustion chamber.

- The resulting explosion forces the piston downward, turning the crankshaft.

This process occurs hundreds of times per minute in each cylinder, highlighting the spark plug’s critical role in engine operation.

The steel shell assembly houses the core insulator unit. The lower portion of the shell is threaded. The ground electrode is welded to the lower portion of the threaded section. The upper portion of the shell is hexagonal is shape, like a bolt head. This hexagonal portion provides a surface for the spark plug spanner. With the help of the spanner, the plug can be screwed into and out of the threaded hole in the cylinder head.

The core insulator is designed to withstand high voltages, pressures as high as 45 kscm and temperatures approximating 2000°C.

The center electrode is housed within the insulator. This is so made without causing distortion, shrinkage or cracking. The electrode is cemented or screwed into the insulator. Sometime, the electrode is secured within the insulator by a fused vitreous seal. This seal ensures perfect sealing under expansion and contraction. The upper end of the center electrode is connected to the terminal of the spark plug wire. The lower end of the center electrode projects beyond the insulator. This end forms a small gap with the ground electrode.

Sealing gaskets are incorporated between the insulator and the shell of the spark plug. These gaskets prevent the escape of gases under various temperature and pressure conditions. A copper gasket is incorporated between the plug shell and the cylinder head. This gasket provides a seal between the two units and helps in the conduction of heat.

The size of the electrode must be fairly substantial to resist burning. The size of the electrode also determines heat transfer. The electrode temperature must be sufficiently high to burn off rapidly any sooty or oily deposit. A compromise is made in deciding the size of the electrodes. As such, the electrode size will vary for different types of engines.

Types of Spark Plugs

There are several types of spark plugs, each designed for specific engine requirements:

a) Copper Core Spark Plugs:

The most common and affordable option, suitable for older vehicles.

b) Platinum Spark Plugs:

More durable than copper, with a longer lifespan.

c) Iridium Spark Plugs:

Offer superior performance and longevity, ideal for high-performance engines.

d) Double Platinum or Iridium Spark Plugs:

Feature precious metals on both electrodes for enhanced durability.

e) Silver Spark Plugs:

Less common, but offer excellent thermal conductivity.

In the past, porcelain or mica were generally used for the spark plug insulator. Presently, oxides of aluminium and silicon are used. The insulator is glazed with a silica coating, expect near the tip. This coating resists adherence of carbon on the surfaces exposed to the combustion gases.

Factors Affecting Spark Plug Performance

Several factors can influence the effectiveness of spark plugs:

a) Heat Range:

The ability of a spark plug to dissipate heat affects its performance and lifespan.

b) Electrode Gap:

The correct gap is crucial for optimal spark generation and engine efficiency.

c) Engine Condition:

Worn engines may require different spark plugs than those in good condition.

d) Fuel Type:

Different fuels may necessitate specific spark plug designs.

e) Driving Conditions:

Frequent short trips or extreme temperatures can impact spark plug wear.

Spark Plug Maintenance and Replacement

Proper maintenance is key to ensuring optimal spark plug performance:

a) Inspection:

Regularly check spark plugs for signs of wear, deposits, or damage.

b) Cleaning:

In some cases, spark plugs can be cleaned to extend their life.

c) Gap Adjustment:

Ensure the electrode gap meets manufacturer specifications.

d) Replacement:

Follow the vehicle manufacturer’s recommendations for spark plug replacement intervals.

Signs of Failing Spark Plugs

Recognizing the symptoms of failing spark plugs can prevent more serious engine issues:

a) Difficulty starting the engine

b) Rough idle or engine misfires

c) Decreased fuel efficiency

d) Loss of acceleration power

e) Engine surge or hesitation

The Impact of Spark Plugs on Engine Performance and Efficiency

a) Smoother Engine Operation:

Consistent spark generation ensures a more stable engine idle and smoother acceleration.

b) Extended Engine Life:

Proper spark plug maintenance helps prevent engine damage and prolongs its lifespan.

Common Spark Plug-Related Issues and Solutions

Addressing common problems associated with spark plugs can help prevent more severe engine damage:

a) Fouled Spark Plugs:

Cleaning or replacing spark plugs can resolve issues caused by fuel deposits or oil contamination.

b) Worn Out Spark Plugs:

Replacing spark plugs at the recommended interval can prevent engine misfires and poor performance.

c) Incorrect Spark Plug Gap:

Adjusting the electrode gap to the manufacturer’s specifications can resolve issues with spark generation.

Conclusion

In conclusion, spark plugs play a vital role in the operation and performance of internal combustion engines. Understanding their function, types, and maintenance requirements can help car owners and enthusiasts optimize engine performance, improve fuel efficiency, and reduce emissions. By recognizing the signs of failing spark plugs and addressing common issues, drivers can prevent more severe engine problems and ensure a smoother, more efficient ride.