Introduction To The Torsion Bar Suspension System In Automobiles

A torsion bar is a type of car suspension system in an automobile that is used in vehicles such as cars, trucks, and vans, A torsion bar suspension system is a significant and acute element of a vehicle’s design. Irrespective of the design, all active suspension systems do the same functions. They keep the tires in contact with the surface of the suburban road, uphold the weight of a vehicle, and absorb the forces produced by the movement and motion of the vehicle.

There are two types of springs that exist in the vehicle market: bending and twisting. Any vehicle suspension that utilizes a torsion bar as its principal weight-bearing spring is known as a torsion bar suspension or torsion spring suspension. The same technique is used in independent torsion bar suspension. However, it is applied to each wheel rather than the complete axle.

What Exactly Is a Torsion?

Torsion is the twisting of a structural member that is subjected to loads (torque) that cause rotation around the member’s longitudinal axis. Torsion is also referred to as rotational twisting. The member is loaded in such a manner that when the stress is applied, it forms a couple around the longitudinal axis and the reaction is a twisting motion around that axis. A push rod or pull rod uses terms like torque, twisting couples, and twisting moments to describe its twisting.

Front Axle

A front axle is the part of the car’s suspension system that connects the wheels to the chassis. There are three types of axles: independent, semi-independent, and full-time. Independent axles have no connection between the steering knuckle and the hub carrier. Semi-independent axles connect the steering knuckle and hub carrier but do not connect them together. Full-time axles connect both parts of the axle together.

Rear Axle

A rear axle is the part of a vehicle’s suspension system that connects its wheels to the chassis. Like the front axle, there are three types of axels: independent, semi-dependent, and full-time dependent. Independent axles have little connection between the steering knuckles and the hubs. Semi-dependent axles connect the steering kinkles and hubs but do not connect the hubs together. Full-time dependent axles connect both parts together.

Torsional Deformations of Cylindrical Bars

A circular shaft’s cross-sections stay flat and undistorted when torsion exposes the shaft. In this situation, people say the bar experiences pure torsion. Because a circular shaft is axi-symmetrical, cross-sections for hollow and solid circular shafts remain plain and undistorted. Noncircular (e.g. square, rectangular) non-axisymmetric shafts deform their cross-sections when exposed to torsion.

Why Are Torsion Bar Suspensions Not Utilized in Two Wheelers?

A specific length restricts the popularity of torsion bars because they require it to function effectively, and space constraints on anything motorcycle-sized prevent installation of a simple and efficient torsion bar suspension.

Which component serves as a spring in a torsion bar suspension?

In vintage Chrysler automobiles, the suspension arm connects to the torsion bar, which the car’s chassis attaches to one end and connects to the suspension arm at the other end via a spline or hex. Compression of the suspension arm attempts to twist the bar, which resists, producing the ‘spring’. A coil spring’s cylindrical material simply becomes a torsion bar tool when straightened out rather than coiled.

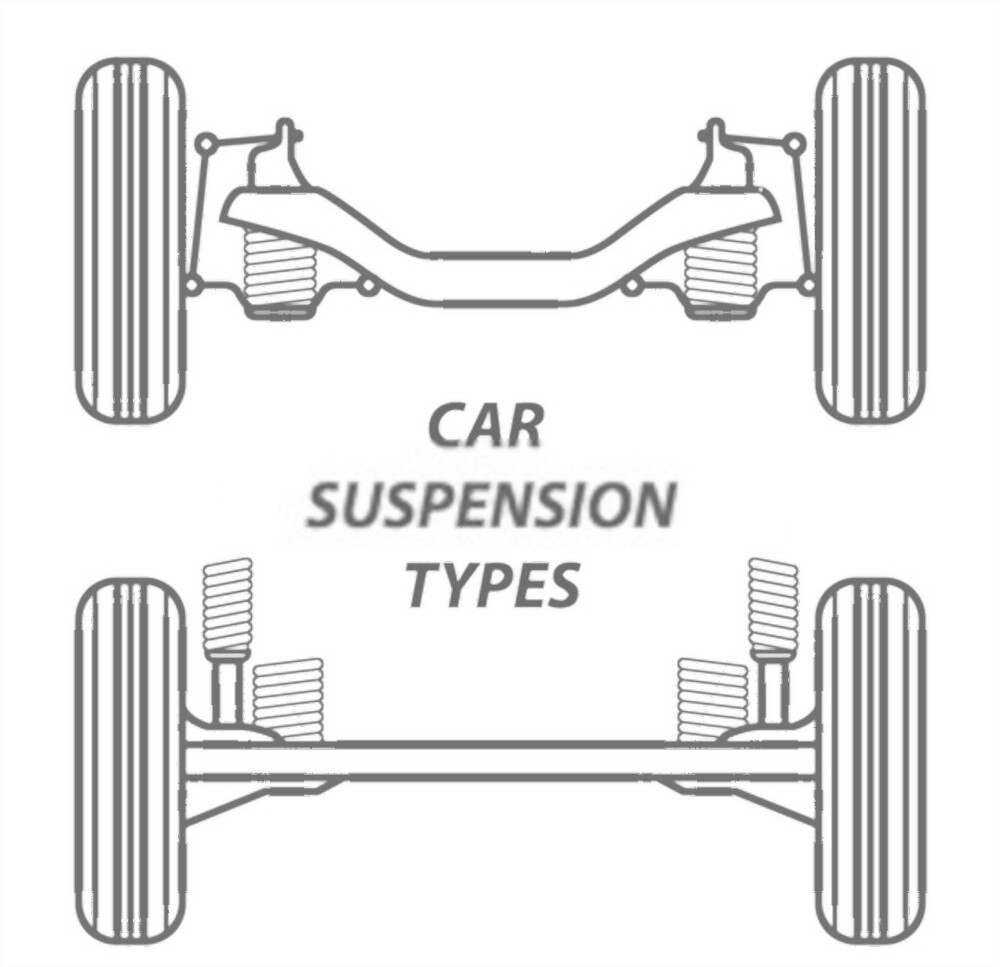

What Is A Dependent Suspension System?

A fundamental and early version of the suspension system has remarkably simple mechanics. This kind features a solid axle connecting both the opposing wheels, which enables them to operate as one unit. Due to dependence, when one wheel experiences an activity, the other will follow. This is widely used in long-haul vehicles.

Examples of a dependent suspension system are: 1. Leaf Spring – is the most traditional one. A series of closely packed plates of steel, connected to the axle, provide the dampening. These plates can be utilized transversely or longitudinally. 2. Beam Axle—Popularly found in front-wheel vehicles. A solid shaft links both the wheels with the inclusion of a track bar. The movement on one wheel produces a response on the other wheel (beam axles may be both “live” and “dead” axles).

What Is An Independent Suspension System?

In an independent suspension system, each wheel and its connections don’t link in a way that every component works independently. Independent Suspension does not really have a single axle linking them, which allows them to react appropriately to the road circumstances, not simply duplicate or alternate the movement of the other wheel.

The independent systems are that they create an experience like you are gliding on the road, smooth and jerk-free. Examples of an Independent Suspension system are: 1. McPherson strut is often referred to as the single wishbone type. In short, there is a wishbone-shaped linkage that gives a mounting point to the axle; A Coil spring is vertically attached to the Chassis of the vehicle. An anti-roll bar is frequently used in such situations to enhance its stiffness. This is a common dampening technique used in today’s vehicles such as in General Motors.

What Is the Semi-Independent Suspension System?

The midway position between the dependent and the independent suspension, as the pseudonym indicates. A wheel functions at some degree of independence, and flexibility of the connections constrains it. This design is used in heavy-duty trucks and similar vehicles.

Popular instances of semi-independent suspension are: 1. Torsion Bar suspension type, also known as Twist Beam Axle type. In the suspension components’ twisting and bending under stress, they produce the dampening effect. A longitudinal crossbeam regulates how each wheel acts. The two wheels respond to deflection independently but yet operate in conjunction, thereby providing themselves with some semi-balance of independence and characterized as semi-independent.

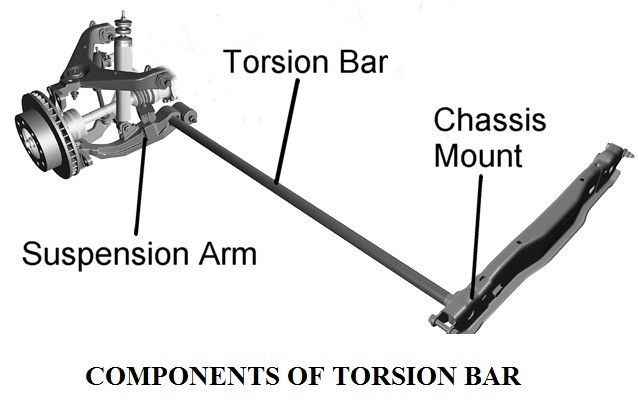

Components of the Torsion Bar suspension system

The key components that constitute the torsion bar suspension system are: Driveshaft or Torsion Bar; lower and upper shoulders or control arms; shock absorber; antiroll bar; front differential; subframe.

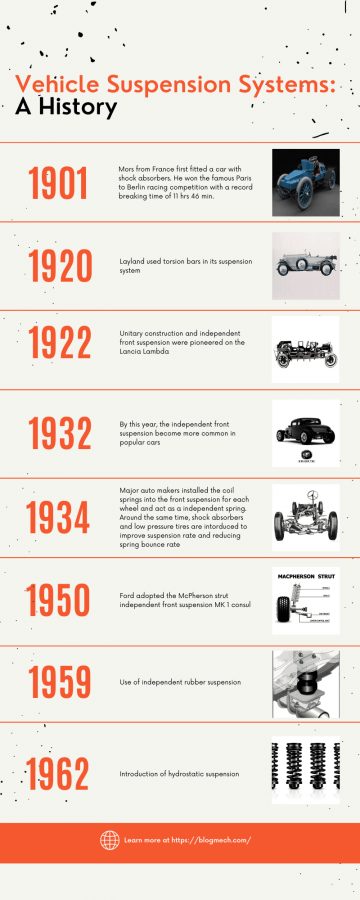

History of the Suspension System

A History Of The Torsion Bar Suspension System

Torsion bar suspension was the first vehicle type to utilize torsion bar suspension, which was introduced in the 1930s. However, this is not completely accurate, since the French fitted a comparable suspension in the Citroen Traction Avant in 1934, which was the first car to do so. Given that the French word for “twisting” is the origin of the word “twisting,” it’s more than clear who will win the title: the one doing the twisting.

Chrysler

The French and Germans introduced torsion bar suspension systems to the international arena, and the Americans quickly began using the most successful torsion bars on Chrysler automobiles as soon as they were introduced.

Porsche

In 1938, the Czech engineer Ledwink updated and refined the torsion bar, and Ferdinand Porsche loved his changes so much that he quickly adopted them in large quantities in his vehicle models.

Porsche appreciates the torsion bar’s biggest benefits, namely, its lightweight and compactness, characteristics that are particularly sought in sports and racing vehicles.

World War II saw extensive use of this kind of suspension in armored vehicles such as the KV-1 and the PANTERA.

Following World War II, virtually all major automobile manufacturers started to include this kind of suspension in some of their models, and the 1950s and 1960s of the twentieth century saw the greatest increase in the use of torsion bar suspensions in automobiles, especially racing cars. Both manufacturers and car customers show a high level of interest for several reasons. They value the compact torsion system’s space-saving design, the affordable installation and maintenance costs, and, most significantly, the long-term reliability of this suspension system.

Jaguar

Jaguar’s E-Type was the first car to utilize a torsion bar as a front suspension system, which debuted in 1961. However, with the passage of time and the introduction of new technologies, the torsion bar system started to lose its appeal and popularity. This kind of suspension becomes much more costly because very complicated, time-consuming, and expensive production processes cause it.

Truck and SUV manufacturers such as Ford, Dodge, Mitsubishi Pajero, General Motors, and others mostly use torsion bar suspension today.

Suspension systems are required in automobiles for the following reasons:

- To absorb shocks and vibrations produced by on and off road imperfections.

- For the purpose of transferring vehicle load to the wheels (supporting the weight),

- For the purpose of ensuring the vehicle’s stability (contact of the wheels with the ground),

- To provide passengers with cushioning and riding comfort throughout their journey.

- To avoid the occurrence of body squats and body dives.

Suspension systems have the following functions:

- To protect people and cargo from the effects of road shocks

- In order to maintain the stability of vehicles in motion (pitching or rolling),

- It is necessary to keep the wheels in constant contact with the road when driving and performing maneuvers such as turning and braking.

- To keep the steering geometry in correct alignment.

- To offer appropriate riding and cushioning characteristics.

- To allow for fast cornering without excessive body roll; and

- To avoid excessive body squats or body dives while cornering.

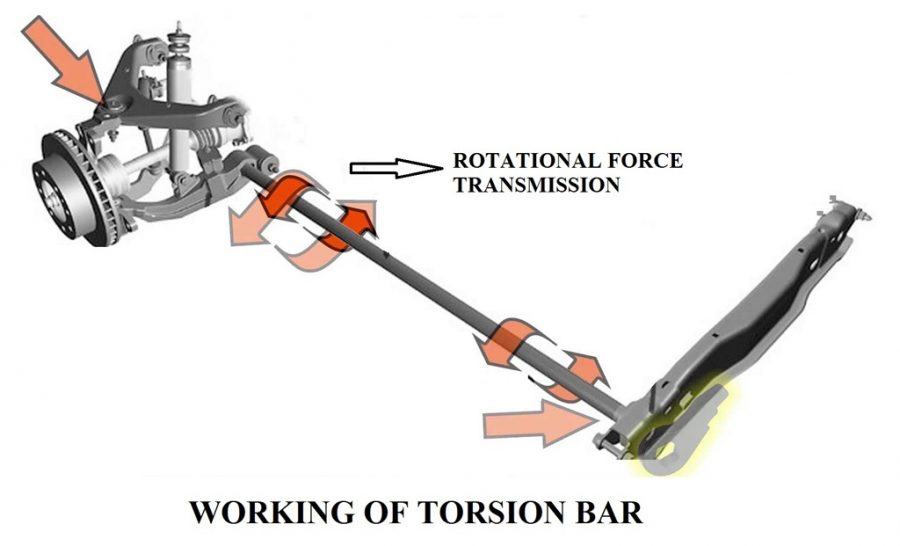

Construction and Working Of A Torsion Bar Suspension System

Torsion bar suspensions are basically metal bars that perform the role of a spring. At one end, the torsion bar mount is rigidly fixed to the vehicle chassis. The last end of the bar may be fastened to the axle, suspension control arm, or a spindle, depending on the vehicle’s design. For instance, when a vehicle travels alongside the road, the forces produced by the motion of the vehicle produce a torque on the bar, which turns it along its axis.

Counteracting the torque is the fact that the torsion bar obviously wants to resist the twisting effect and return to its normal state. By doing so, the suspension supplies a level of resistance to the forces generated by the movement of the vehicle. This resistance is the basic principle behind a torsion bar suspension system, which makes the comfortable ride.

The Working of the Torsion Bar Suspension System

Torsion bars or twist beam suspension use the twisting properties of a steel bar to offer coil-spring-like functions. The technician fixes one end of a bar rigidly to the vehicle frame. They fasten the far end to a wishbone, which acts like a lever that travels perpendicular to the torsion bar. When a stone or projection hits the wheel, the vertical motion shifts to the wishbone. From there, the levering action moves the force to the torsion bar. The torsion bar adjustment then twists sideways on its axis to offer the spring force. European car manufacturers used this system widely, as did Packard and Chrysler in the United States, through the 1950s and 1960s.

Advantages of Torsion Bar Suspension System

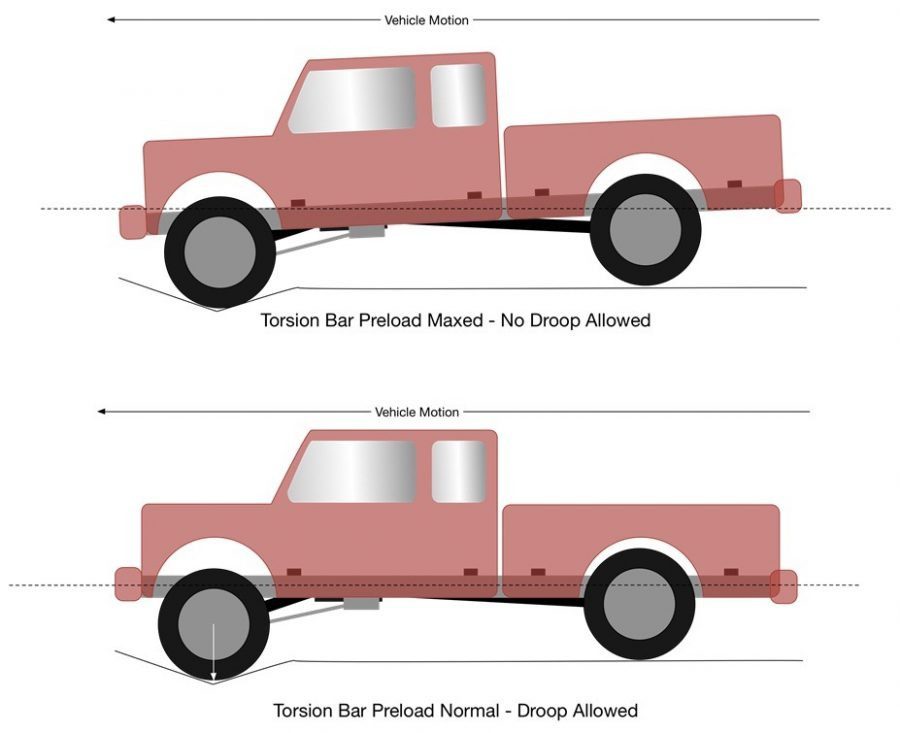

In this system, there are several key advantages. The design of the torsion bar suspension takes up less area than other suspension systems. This forces the vehicle designers to create a more spacious passenger compartment. The elevation of the bars can also be varied more easily than with other suspension systems. They are also extremely durable and usually have a long service life.

Disadvantages Of Torsion Bar Suspension System

There are also several disadvantages to torsion bar suspensions. These bars generally do not offer what’s known as a progressive spring rate. In suspensions with a progressive spring, the design typically spaces the coils of the spring at dissimilar distances from each other. This permits the suspension system to aid braking, firm steering and handling while still providing for a smooth and comfortable journey. Torsion bar tuners repeatedly adjust vehicles to either deliver a more firm driving experience at the expense of ride smoothness, or a smoother ride at the expense of the vehicle’s handling quality.

Torsion Bar Suspension System Application

These Torsion bars were originally developed for military applications. Their unique design allowed for the vehicle to remain stable even if the ground was uneven. Because of this, they became popular in off-road racing and motorcycle riding. Today, torsion bars are commonly used in cars, trucks, SUVs, tanks, and motorcycles.

Recent Trends in Torsion Bar Suspension Systems

Torsion bar suspension systems were once relatively common in passenger vehicles, but today they are used mainly for the air suspension systems of trucks and sport utility vehicles. Some famous automobiles that used this type of air suspension were the original Porsche 356, the Volkswagen Beetle, the Porsche 911 models that utilized an air-cooled engine, and significantly, the Chrysler line-up of cars from the late 1950s through the late 1980s.

Compared to multi-link suspensions, torsion beam suspension is generally mechanically simpler, may be lighter, and are usually easier to package. This is a highly significant advance, especially in the field of cargo space. Torsion beams typically sit lower in a car, something that frequently provides additional trunk space. This is likewise true with the Mazda3 in 2020. The redesigned compartment is deeper and more versatile than before. One of the greatest issues with torsion is unsteady driving while cornering.

Driving a vehicle with torsion in quick bends needs a lot of attention and expertise on the part of the driver. Another drawback is extra vibrations that are conveyed when the vehicle stops. These vibrations are particularly severe towards the back of the vehicle, and this does not help at all with the comfort of passengers in the rear seats. Popular SUVs frequently utilize this type of torsion bar suspension system, and it serves as a front suspension.

FAQs:

The purpose of a suspension damper is to

a. Resist the off road shocks

b. Reduce the bump stroke of the spring

c. Absorb the energy stored in the spring

d. All of the above

Answer d. All of the above

An axle is located on a leaf spring by an

a. U-bolt

b. Spring clip

c. Centre bolt

d. Shackle pin

Answer: c. Center bolt

Why a laminated spring is made up of a series of leaves is to

a. Reduce inter leaf friction

b. Soften the spring action and increase the maximum deflection

c. Allow the leaves to slide during the bump movement.

d. Overcome the weakness at the center of a single leaf spring

Answer: d. Overcome the weakness at the center of a single leaf spring

In the case of the clutch, if the spring becomes weak, the remedy lies in

a. Tightening further the springs

b. Interchanging the springs

c. Retempering the springs

d. Replacing the springs

Answer: d. Replacing the springs

The stabilizer bar reduces the tendency of the vehicle to roll when

a. Taking turns

b. In straight

c. Normal condition

d. High speed

Answer: a. Taking turns

In a wishbone type suspension system, ______________ may vary.

a. Caster angle

b. Toe in

c. Toe out

d. Camber angle

Answer: d. Camber angle

Which of the following is an advantage of an independent suspension system?

a. Elastic strain energy stored in a coil spring is greater

b. Unsprung weight is reduced.

c. A softer spring can be used without increasing the rolling effect.

d. None of these

Answer: a. Elastic strain energy stored in a coil spring is greater

Another name for a shock absorber is:

a. Damper

b. Torsion bar or anti roll bar

c. Spring

d. Independent suspension

Answer: a. Damper

The torsion bar suspension can not take up driving and torque effectively.

a. Braking

b. Accelerating

c. Moving

d. None of these

Answer: b. Accelerating